Waterproof encapsulation structure and its integrated molding process

A technology of packaging structure and processing technology, which is applied in gas/waterproof devices, lighting devices, semiconductor devices, etc., can solve the problems of inability to resist pressure, sealing failure, etc., and achieve good sealing effect and high-grade sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The waterproof encapsulation structure of the present invention will be described below with reference to the drawings and specific embodiments of the present invention, and the integrated molding process for completing the waterproof encapsulation structure will be further described in detail in conjunction with the mold diagram.

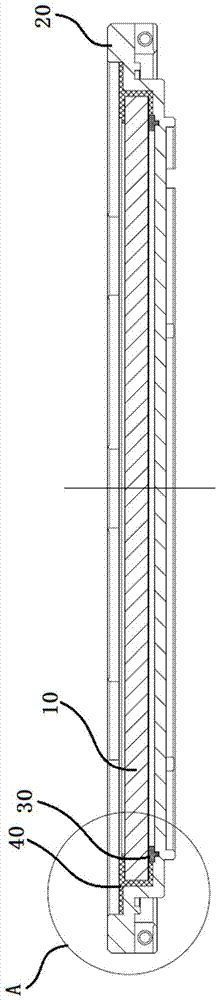

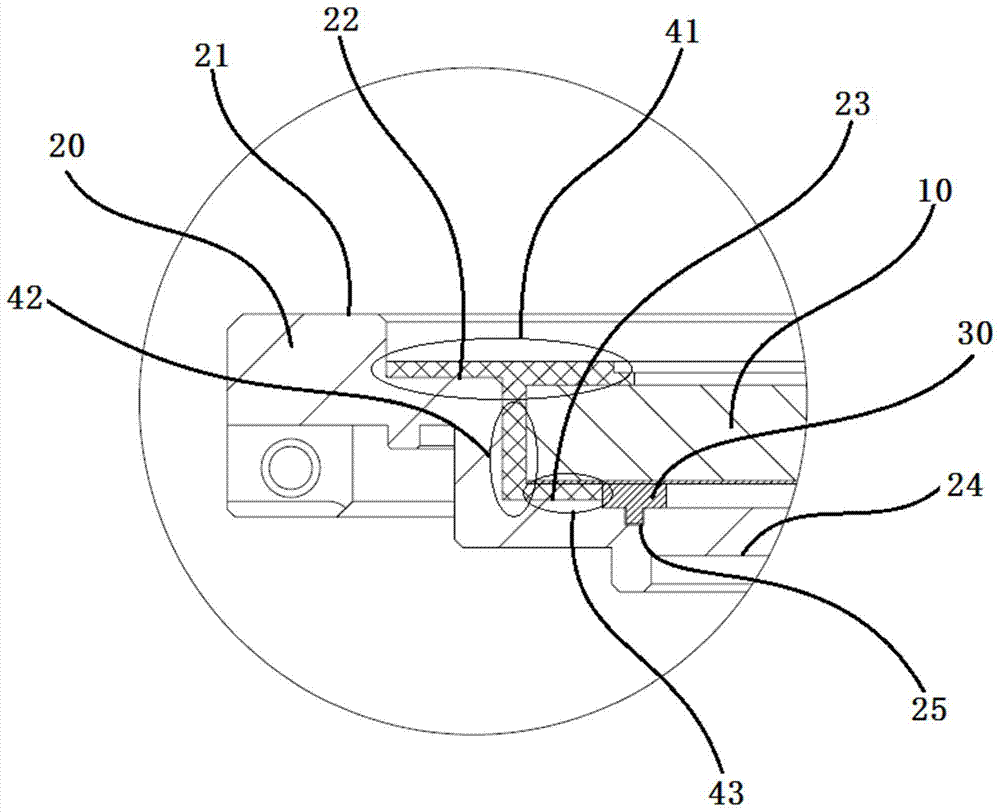

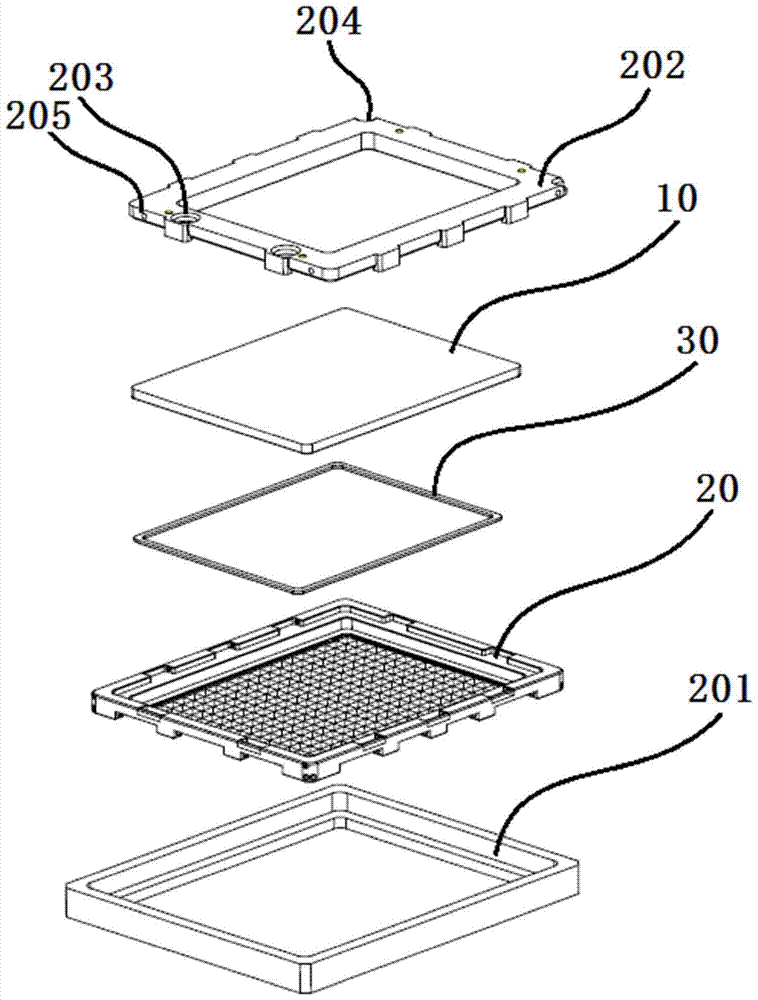

[0031] Please refer to the attached figure 1 : It shows the completed structure of the waterproof encapsulation structure, and it can be seen from the figure that the waterproof encapsulation structure includes a transparent cover sheet 10, a grid 20 and a T-shaped sealing rubber ring 30. In fact, the T-shaped sealing rubber ring 30 is directly installed on the grid, and the transparent cover is directly pressed on the T-shaped sealing rubber ring, and the cover is set above the grid. Sealed space, that is, a waterproof sealing system that can accommodate heat transfer oil inside the grid as the main body.

[0032] The grid 20 includes a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com