Forming construction method of long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall

A technology of long auger drilling and pile slabs, which is applied in sheet pile walls, artificial islands, water conservancy projects, etc., can solve the problems of long construction period, large equipment investment, and large cement slurry loss, so as to reduce material input and expand development Significant effects of space and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

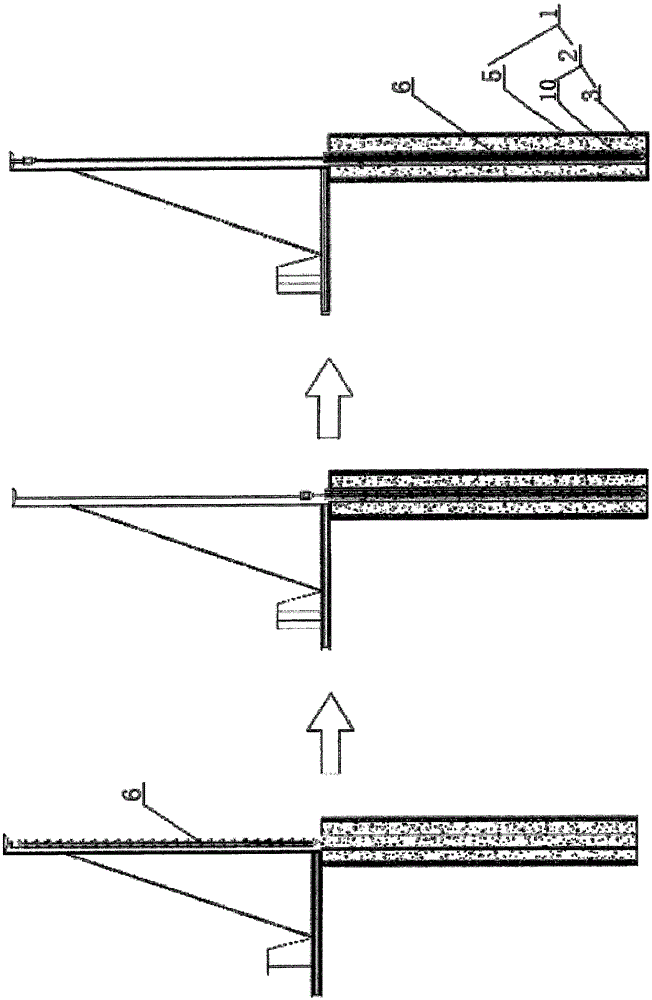

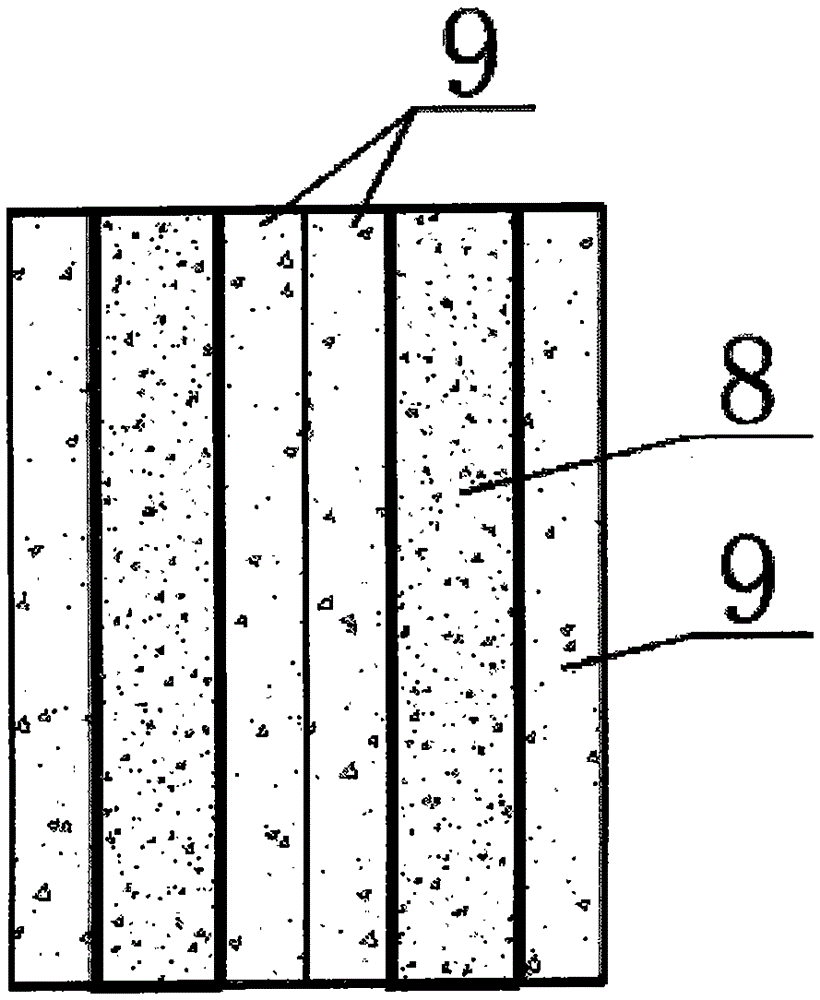

[0031] Such as figure 1 , image 3 and Figure 5 The shown long helical drilled high-spray cement-soil composite plain concrete pile-slab composite pile includes a plurality of plain concrete pile-slabs; A pile 5 is formed; a high-pressure rib cavity 7 is formed between the cement-soil pile 5 and the pile body 2; the high-pressure rib cavity 7 and the pile body 2 form an enlarged rib concrete body 3 through concrete pressure filling; The concrete body 3 of the expanded diameter rib plate is arranged along the depth direction of the pile body; the plain concrete pile 8 is arranged inside the pile body 1; the plain concrete pile 8 is composed of a concrete pouring pile plate and a cement-soil pile; Plain concrete ribs 9 are arranged between the plain concrete piles 8 .

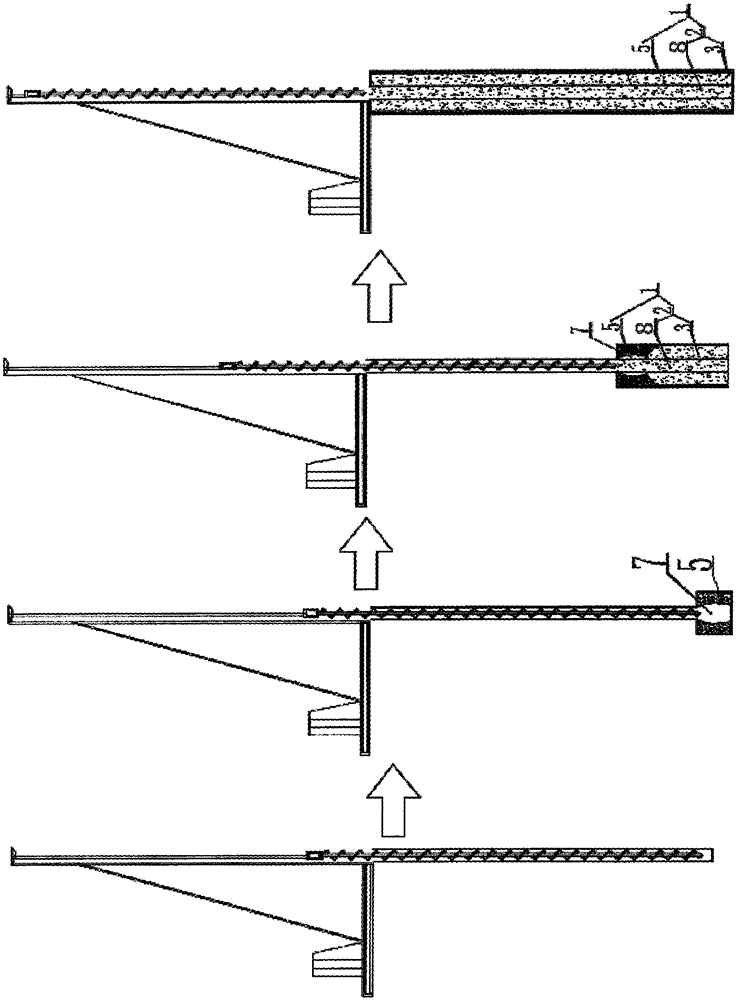

[0032] A method for forming a long spiral hole-forming pile sheet pile support and an anti-seepage diaphragm wall, comprising the following steps:

[0033] Step 1: Construction preparation. Before constructi...

Embodiment 2

[0038] Such as figure 2 , Figure 4 and Figure 6The shown long helical drilled high-sprayed cement-soil composite reinforced concrete pile-slab composite pile includes a plurality of reinforced concrete pile-slabs; A pile 5 is formed; a high-pressure rib cavity 7 is formed between the cement-soil pile 5 and the pile body 2; the high-pressure rib cavity 7 and the pile body 2 form an enlarged rib concrete body 3 through concrete pressure filling; The expanded-diameter ribbed concrete body 3 is arranged along the depth direction of the pile body 2; the inside of the pile body 1 is provided with a reinforced concrete pile 10; formed; plain concrete ribs 9 are arranged between adjacent reinforced concrete piles 10 .

[0039] A method for forming a long spiral hole-forming pile sheet pile support and an anti-seepage diaphragm wall, comprising the following steps:

[0040] Step 1: Construction preparation. Before construction, prepare for three links and one leveling on the sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com