Low pressure power steering tube rubber composition with chlorinated polyethylene rubber as main component

A technology of rubber composition and chlorinated polyethylene, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor control of extrusion size, high material and processing costs, and fewer manufacturers. Achieve the effect of low price, high mechanical performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Chlorinated polyethylene rubber 100 parts,

[0030] Quickly squeeze out 40 parts of carbon black,

[0031] 20 parts of medium particle thermal cracking carbon black,

[0032] Calcium Hydroxide 10 parts,

[0033] 20 parts of dioctyl esters,

[0034] 7 parts of magnesium oxide,

[0035] 3 parts epoxy resin,

[0036] Anti-aging agent NBC 1 part,

[0037] Diallyl phthalate 6 parts,

[0038] 6 parts of 1,4-bis-tert-butylperoxycumene.

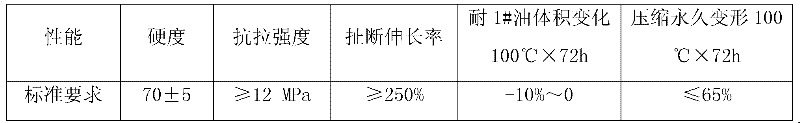

[0039] Performance of Example 1: hardness 72.5, tensile strength 12.9MPa, elongation 273%; 100°C×72h resistant to 1# oil volume change rate at -4.9%; 100°C×72h compression set 50.2%.

Embodiment 2

[0041] Chlorinated polyethylene rubber 100 parts,

[0042] Quickly squeeze out 45 parts of carbon black,

[0043] Medium particle thermal cracking carbon black 15 parts,

[0044] Calcium Hydroxide 10 parts,

[0045] 30 parts of dioctyl esters,

[0046] 11 parts of magnesium oxide,

[0047] 5 parts of epoxy resin,

[0048] Anti-aging agent NBC 1 part,

[0049] Diallyl phthalate 8 parts,

[0050] 7.5 parts of 1,4-bis-tert-butylperoxycumene.

[0051] Performance of Example 2: hardness 69.5, tensile strength 16.3MPa, elongation 302%; 100°C×72h resistance to 1# oil volume change rate at -3.4%; 100°C×72h compression set 51.3%.

Embodiment 3

[0053] Chlorinated polyethylene rubber 100 parts,

[0054] Quickly squeeze out 50 parts of carbon black,

[0055] 10 parts of medium particle thermal carbon black,

[0056] Calcium Hydroxide 10 parts,

[0057] 20 parts of dioctyl esters,

[0058] 9 parts of magnesium oxide,

[0059] 4 parts epoxy resin,

[0060] Anti-aging agent NBC 1 part,

[0061] Diallyl phthalate 7 parts,

[0062] 6.5 parts of 1,4-bis-tert-butylperoxycumene.

[0063] Performance of Example 3: hardness 74.3, tensile strength 14.7MPa, elongation 281%; 100°C×72h resistant to 1# oil volume change rate at -5.1%; 100°C×72h compression set 52.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com