Polycarbonate and acrylic nitrile-butadiene-phenylethylene grafted copolymer heat resisting and flame-retardant alloy

A graft copolymer and styrene technology, applied in the field of alloy resins, can solve the problems of lowering heat distortion temperature, large amount of addition and high price, and achieve the effects of increasing heat distortion temperature, stable product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

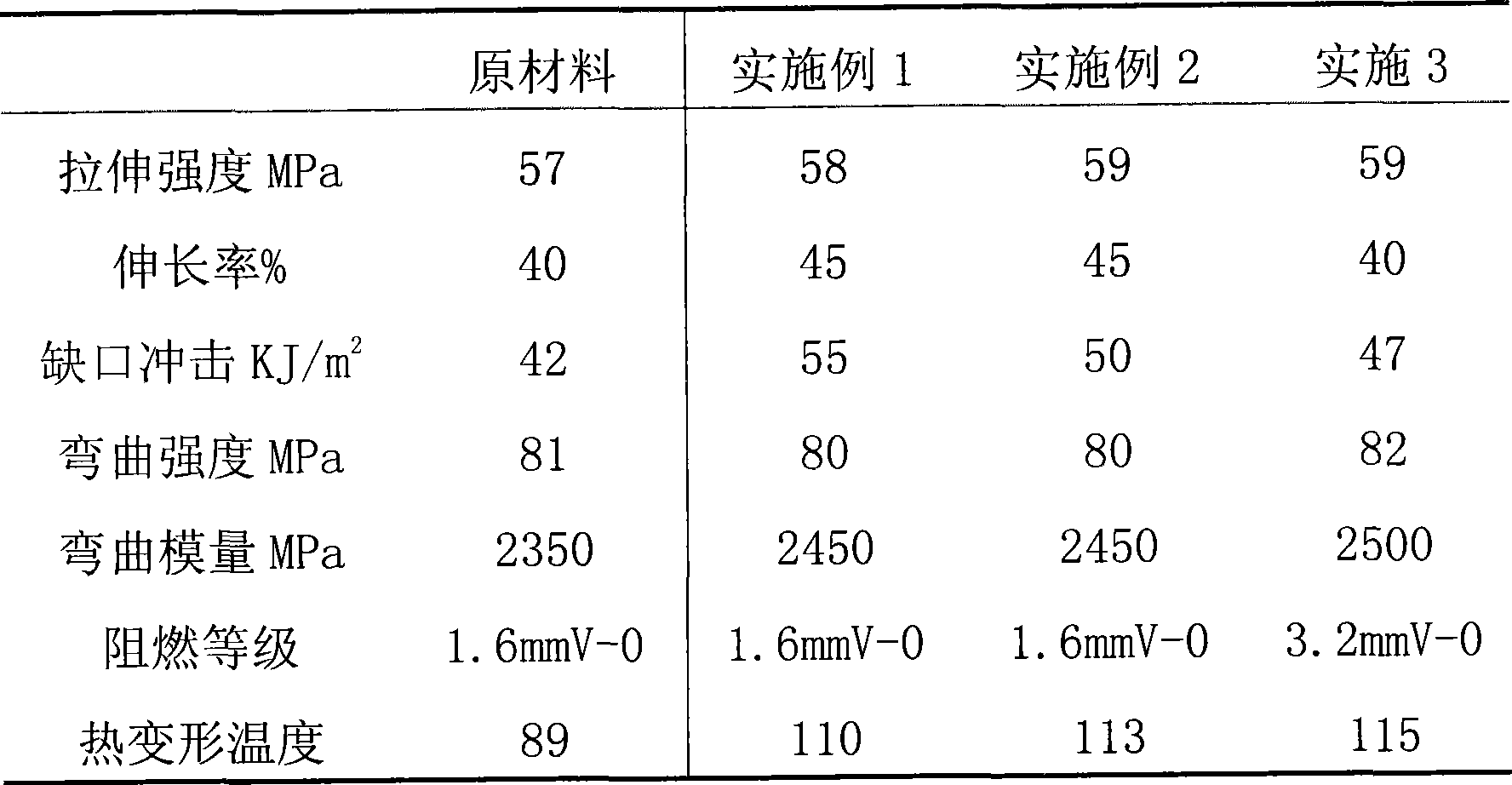

[0034] The raw material formula used in this embodiment:

[0035] The PC resin is selected from GE's 121R.

[0036] ABS resin is 707 made by Taiwan CHIMEI Company.

[0037] The flame retardant is made of Resorcinol bisphosphate from Copolya and PPS from GE.

[0038] The heat-resistant modifier is α-methylstyrene from Taiwan Chi Mei Company.

[0039] The toughening agent is 1125AC from DUPONT.

[0040] The light and heat stabilizer chooses CIBA refined 1010 and 168;

[0041] The processing lubricating aid in the processing aids is made of domestic EBS, and a small amount of white mineral oil is commonly used in industry.

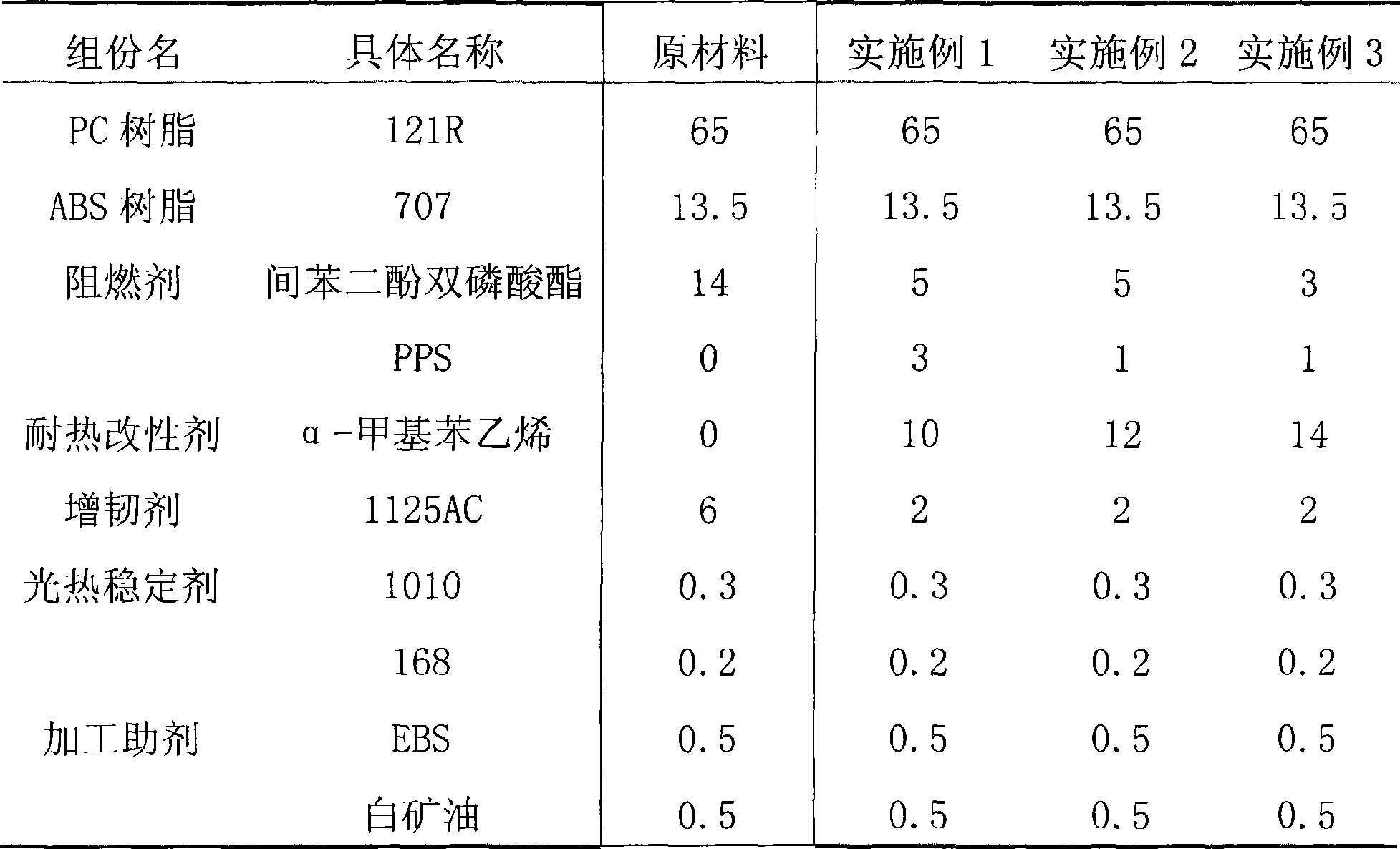

[0042] Attached Table 1. Specific formula corresponding to the embodiment

[0043]

[0044] A preparation method of halogen-free flame-retardant and heat-resistant polycarbonate and acrylonitrile-butadiene-styrene graft copolymer alloy resin is:

[0045]The first step. Weigh PC and ABS resins, flame retardants, heat-resistant modifiers, toughening agents and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com