3D printing modified polylactic acid material and preparation method thereof

A polylactic acid material, 3D printing technology, applied in rayon manufacturing, single-component polyester rayon, fiber chemical characteristics, etc., can solve the problems of low impact strength, poor heat resistance, poor toughness, etc., and achieve impact strength Improvement, high product quality and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

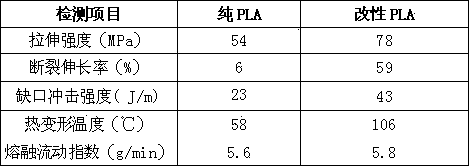

Embodiment 1

[0033] 1) 70 parts by weight of polylactic acid, 5 parts of dibutyl alcohol diisocyanate, 5 parts of polyhydrocarbyl acrylate, 1 part of 6000 mesh montmorillonite, 5 parts of polyacrylate with molecular polymerization degree of 40, 5 parts 1 part of nano silicon dioxide and 0.5 part of composite antioxidant are added to a low-temperature planetary ball mill, fully mixed and ground for 2 hours at a temperature of -15 degrees Celsius and a speed of 300 r / min, and then discharged;

[0034] 2) The mixture obtained in step 1) and 5 parts of polybutylene succinate were mixed and extruded into pellets with a single-screw extruder, and the residence time of the materials in the extruder was 2 minutes. The screw diameter of the single-screw extruder is 75mm, the aspect ratio is 20:1, the temperature of the extruder is set as follows: 170°C, 175°C, 185°C, 190°C, 185°C, and the die head temperature is 205°C;

[0035]3) Dry the particles made in step 2) at a temperature of 50° C. for 2 ho...

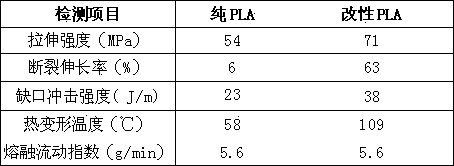

Embodiment 2

[0039] 1) 75 parts by weight of polylactic acid, 3 parts of polymethyl diisocyanate, 2 parts of polyhydrocarbyl trimethacrylate, 2 parts of 6000 mesh talcum powder, 4 parts of polyvinyl alcohol with a molecular polymerization degree of 50, 3 parts of nano-calcium carbonate and 0.6 part of composite antioxidant were added to a low-temperature planetary ball mill, and the mixture was fully mixed and ground for 1.5 hours at a temperature of -10 degrees Celsius and a speed of 350 r / min, and then discharged;

[0040] 2) Mix the mixture obtained in step 1) and 8 parts of polybutylene adipate with a single-screw extruder to extrude and pelletize. The residence time of the materials in the extruder is 1.5 minutes. The screw diameter of the single-screw extruder is 75mm, the aspect ratio is 20:1, the temperature of the extruder is set as follows: 180°C, 185°C, 195°C, 200°C, 190°C, and the die head temperature is 205°C;

[0041] 3) Dry the particles made in step 2) at a temperature of 5...

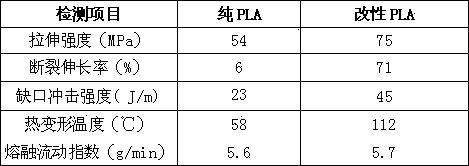

Embodiment 3

[0045] 1) 80 parts by weight of polylactic acid, 5 parts of polymethyl diisocyanate, 3 parts of polyhydrocarbyl acrylate, 2 parts of 8000 mesh montmorillonite, 5 parts of polylactic acid with a molecular polymerization degree of 80, 2 parts Add nano-silica and 0.8 parts of composite antioxidant to a low-temperature planetary ball mill, fully mix and grind for 2 hours at a temperature of -10 degrees Celsius and a speed of 300 r / min, and then discharge;

[0046] 2) Mix the mixture obtained in step 1) with 8 parts of poly(adipic acid-succinic acid) butanediol copolyester with a single-screw extruder and extrude to pelletize, and the material stays in the extruder The time is 2 minutes. The screw diameter of the single-screw extruder is 75mm, the aspect ratio is 20:1, the temperature of the extruder is set as follows: 180°C, 185°C, 190°C, 200°C, 195°C, and the die head temperature is 210°C;

[0047] 3) Dry the particles made in step 2) for 3 hours at a temperature of 50° C. and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com