Inorganic nano particle modified high performance recovery plastic and its preparing process

A technology of inorganic nanoparticles and recycled plastics, applied in the field of composite materials, can solve problems such as the limitation of recycling ratio, the performance degradation of mixed recycled plastics, and the performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

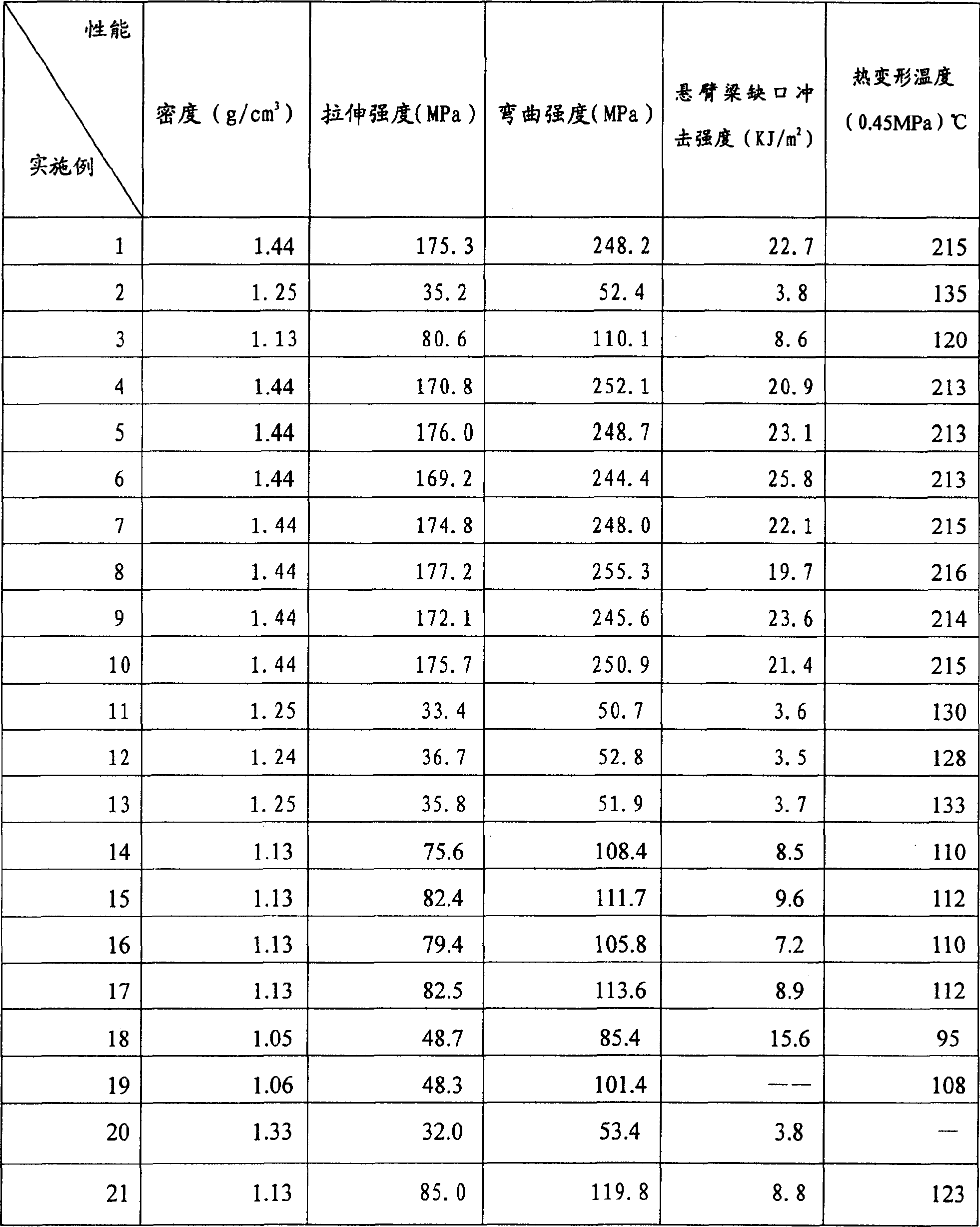

Examples

Embodiment 1

[0025] (A) 5kg of reclaimed nylon 6 resin, i.e. polyamide 6;

[0026] (B) nylon 6 resin (polyamide 6) new material of 40kg;

[0027] (C) 5kg of nano-calcium carbonate, D 98 = 10nm;

[0028] (D) maleic anhydride grafted ethylene propylene diene rubber (EPDM) of 5kg;

[0029] (E) 45kg of non-alkali glass fiber.

[0030] The above components are prepared by the following process to prepare inorganic nano particle modified high-performance recycled plastics.

[0031] Step 1: After 5 kg of recycled nylon 6 resin is routinely sorted, crushed, dried and removed of metal impurities, it is fully mixed with a mixer, and the speed of the mixer is controlled at 20-rpm;

[0032] Step 2: Put 5kg, D 98 Add 0.0255kg of calcium stearate dispersant to the nano-calcium carbonate inorganic nanoparticles of =10nm and fully mix in the mixer. The mixer speed is controlled at more than 400rpm. The process parameters are: heating temperature: 40°C, holding time: 5 minutes ;

[0033] Step 3: 5kg...

Embodiment 2

[0036] (A) 35kg of reclaimed polypropylene (PP) resin;

[0037] (B) 30kg polypropylene (PP) resin new material;

[0038] (C) 30kg of talcum powder particles, D 98 = 10 nm.

[0039] (D) maleic anhydride grafted polyethylene (PE) of 5kg;

[0040] The above components are prepared by the following process to prepare inorganic nano particle modified high-performance recycled plastics.

[0041] Step 1: After conventional sorting, crushing, drying and removal of metal impurities, 35kg of recycled polypropylene (PP) resin is fully mixed by a mixer, and the speed of the mixer is controlled at 400rpm;

[0042] Step 2: Put 30kg, D 98 = Add 0.3kg of titanate coupling agent dispersant to the talcum powder particles of 10nm and fully mix in the mixer. The speed of the mixer is controlled at more than 400rpm. The process parameters are: heating temperature: 80°C, holding time: 30 minutes;

[0043] Step 3: 5kg of maleic anhydride grafted polyethylene (PE) and 35kg of recycled polypropyl...

Embodiment 3

[0046] (A) 98kg of reclaimed nylon 66 resin (polyamide 66);

[0047] (B) 1 kg of acrylate copolymer;

[0048] (C) 1kg of nano-montmorillonite, D 98 = 10 nm.

[0049] The above components are prepared by the following process to prepare inorganic nano particle modified high-performance recycled plastics.

[0050] Step 1: 98kg of recycled nylon 66 resin (polyamide 66) is subjected to conventional sorting, crushing, drying and metal impurity removal treatment, then fully mixed by a mixer, and the speed of the mixer is controlled at 200rpm;

[0051] Step 2: Add 1kg, D 98 = Add 0.01kg of silane coupling agent to the 10nm nano-montmorillonite and fully mix in the mixer. The mixer speed is controlled at more than 400rpm. The process parameters are: heating temperature: 60°C, holding time: 20 minutes;

[0052] Step three: the acrylate copolymer of 1kg and the recycled nylon 66 resin (polyamide 66) of 98kg after step one treatment and the 1kg after step two treatment, D 98 The nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com