Montmorillonite layered nylon6/montmorillonite nano composite material and preparation thereof

A nano-composite material and montmorillonite technology are applied in the field of layered nylon 6/montmorillonite nano-composite materials and their preparation, which can solve the problems that do not involve the preparation of layered nylon 6, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

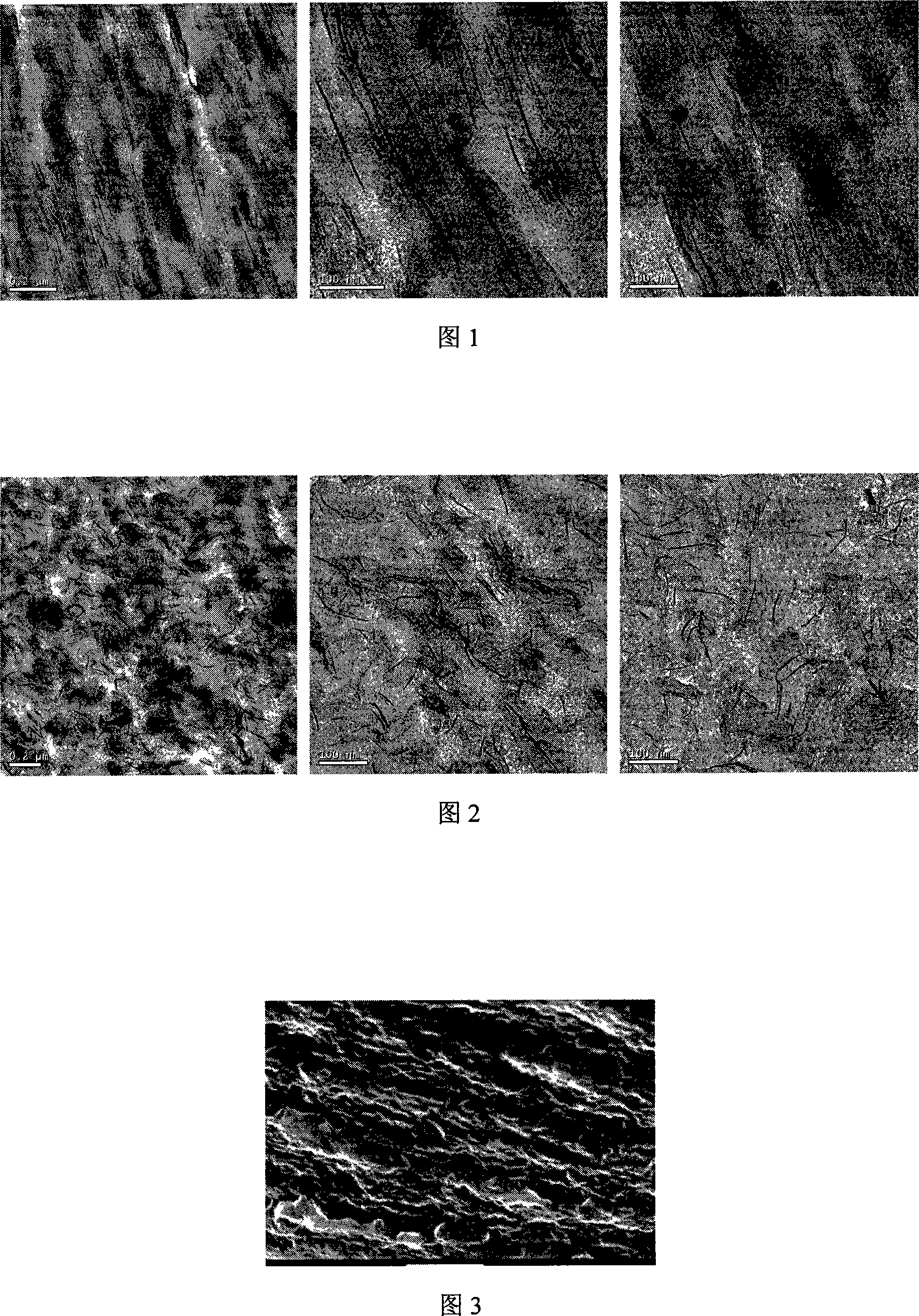

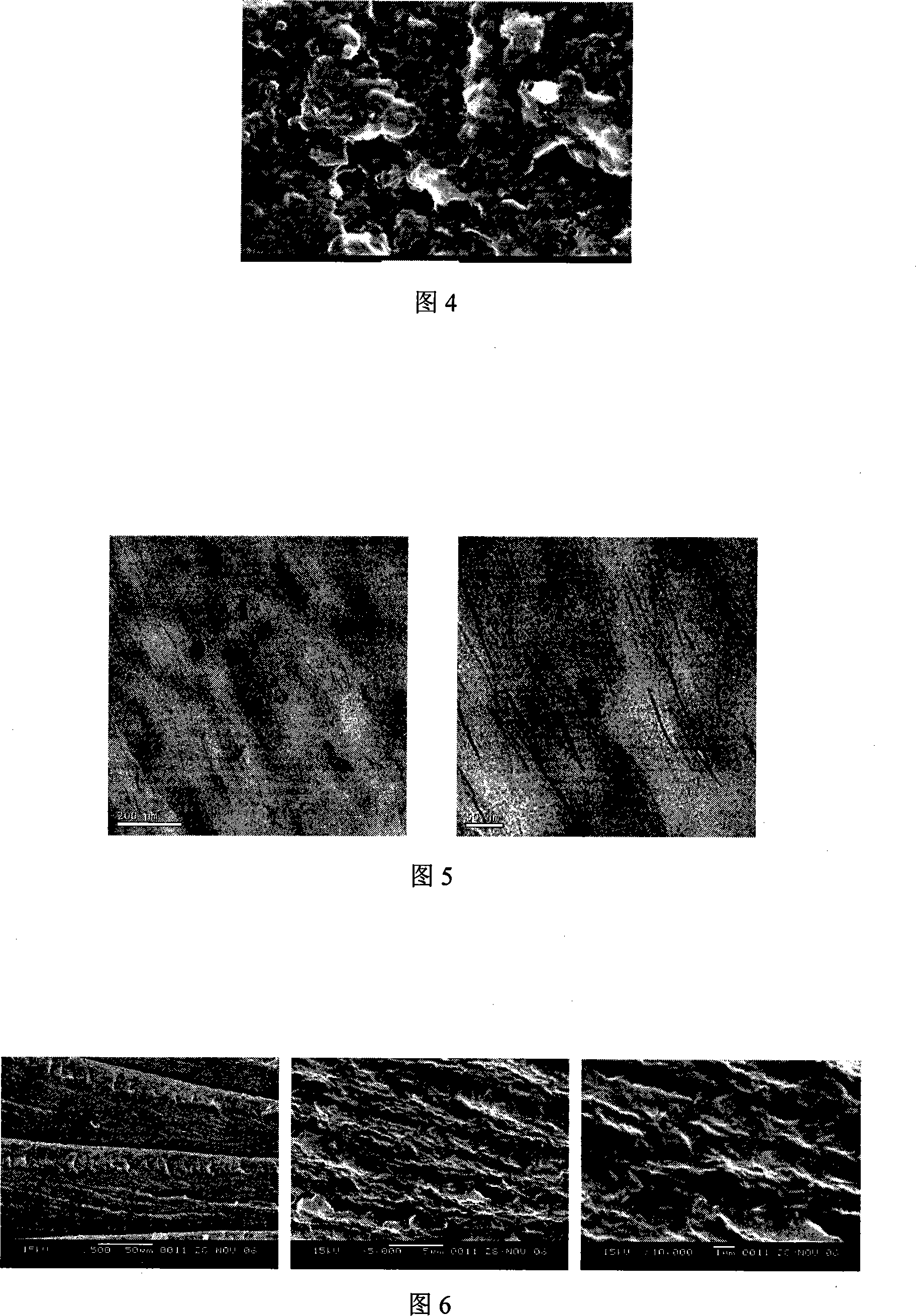

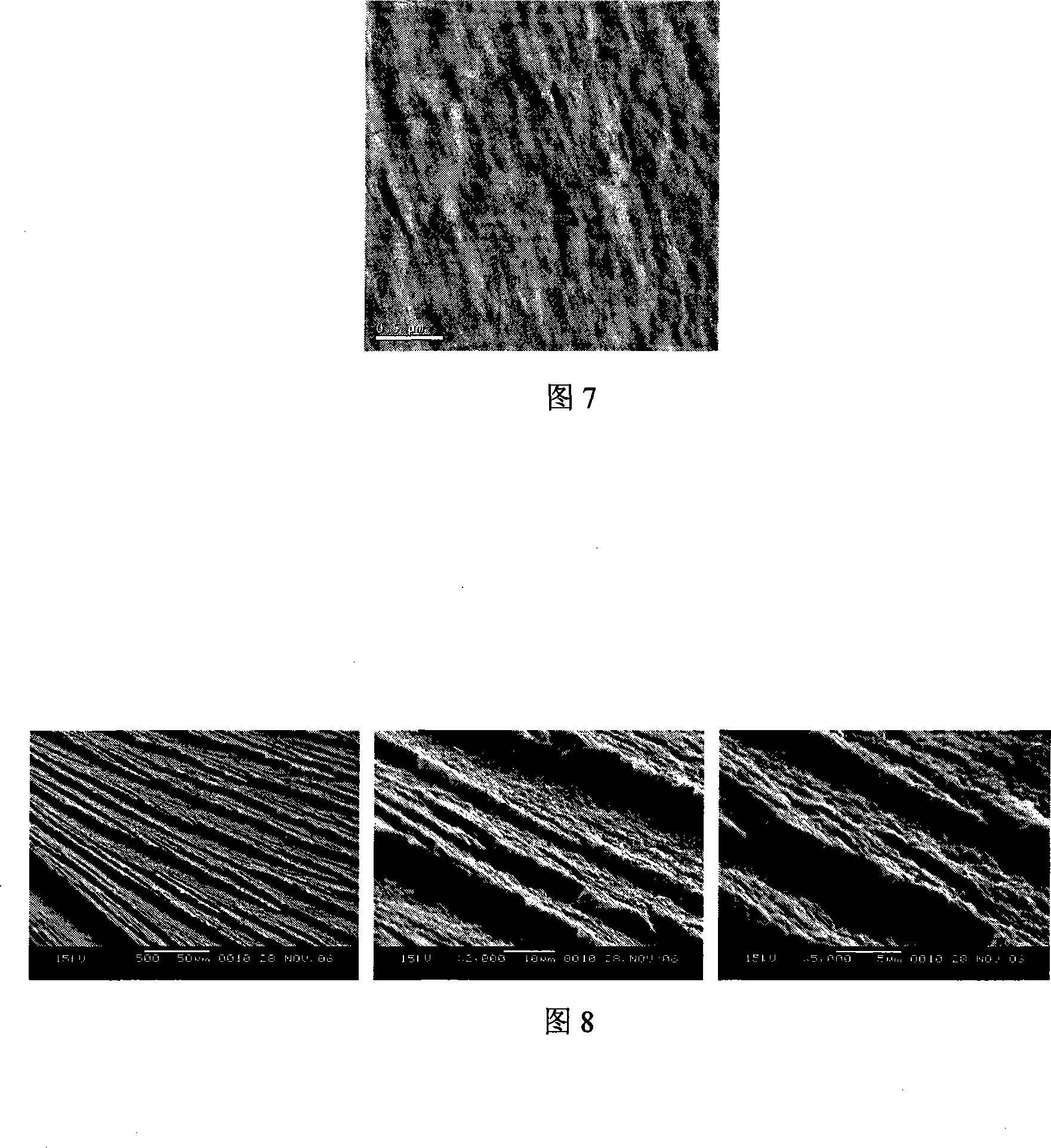

[0028] Pre-blended 1000g of dry nylon 6, 30g of modified montmorillonite, and 2g of antioxidant 1010, melted and blended twice on a twin-screw extruder with a four-stage temperature range of 125-255°C, and granulated to obtain montmorillonite Intercalated nanocomposites with 3% soil content. Vacuum dry in a drum oven at a constant temperature of 110°C for 7 hours. After being processed by an injection molding machine (outlet temperature 230°C, mold temperature 20°C, melt pressure 60.0bar), the preformed sample is placed in a rectangular mold with a piston, and the temperature is constant. 80°C, apply a pressure of 650Mpa with a flat vulcanizer, and keep the pressure for 5 minutes. The sample is taken out from the mold, and the nylon 6 / montmorillonite nanocomposite material with special microscopic morphology is obtained. The tensile elongation at break of the material is 131%; its low-temperature ultrathin section can be observed under the transmission electron microscope to ...

Embodiment 2

[0030] 1500g of nylon 6, 75g of modified montmorillonite, and 3g of antioxidant 1010 were pre-blended, melted, blended and granulated twice through a twin-screw extruder to obtain a nanocomposite material containing 5% of montmorillonite. Vacuum dry in a drum oven at a constant temperature of 100°C for 6 hours. After being processed by an injection molding machine (outlet temperature 230°C, mold temperature 40°C, melt pressure 80.0bar), the preformed strip is placed in a rectangular mold with a piston, and the temperature is constant. 40°C, apply a pressure of 800Mpa with a flat vulcanizer, and keep the pressure for 10 minutes. The sample was taken out from the mold, and a nylon 6 / montmorillonite nanocomposite material with special microscopic morphology was obtained. The tensile elongation at break of the material is 176%; its cryogenic ultrathin section can be observed under the transmission electron microscope that the montmorillonites are arranged parallel to each other (F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com