High-performance polylactic acid blow molding thin film and preparation method thereof

A technology of blown film and polylactic acid, which is applied in the field of high-performance polylactic acid blown film and its preparation, can solve the problems of poor performance of blown film, achieve transparency, maintain complete biodegradation, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of high-performance polylactic acid blown film of the present invention comprises the following steps:

[0022] Step 1. Dry the polylactic acid with crystallization ability and directly perform cold crystallization treatment (the method is annealing), or first dry the polylactic acid with crystallization ability, extrude granulation, dry, and then perform cold crystallization treatment (the method is annealing ), obtain crystallized polylactic acid material;

[0023] Step 2: blowing the crystallized polylactic acid obtained in step 1 into a film at 150-160° C. to obtain a high-performance polylactic acid blown film.

[0024] In the above technical solution, in step 1, the cold crystallization temperature of polylactic acid with crystallization ability is 90-120°C.

[0025] In the above technical solution, in step 1, a twin-screw extruder is used for extrusion and granulation, and the setting conditions of the twin-screw extruder are: Zone 1: 165-...

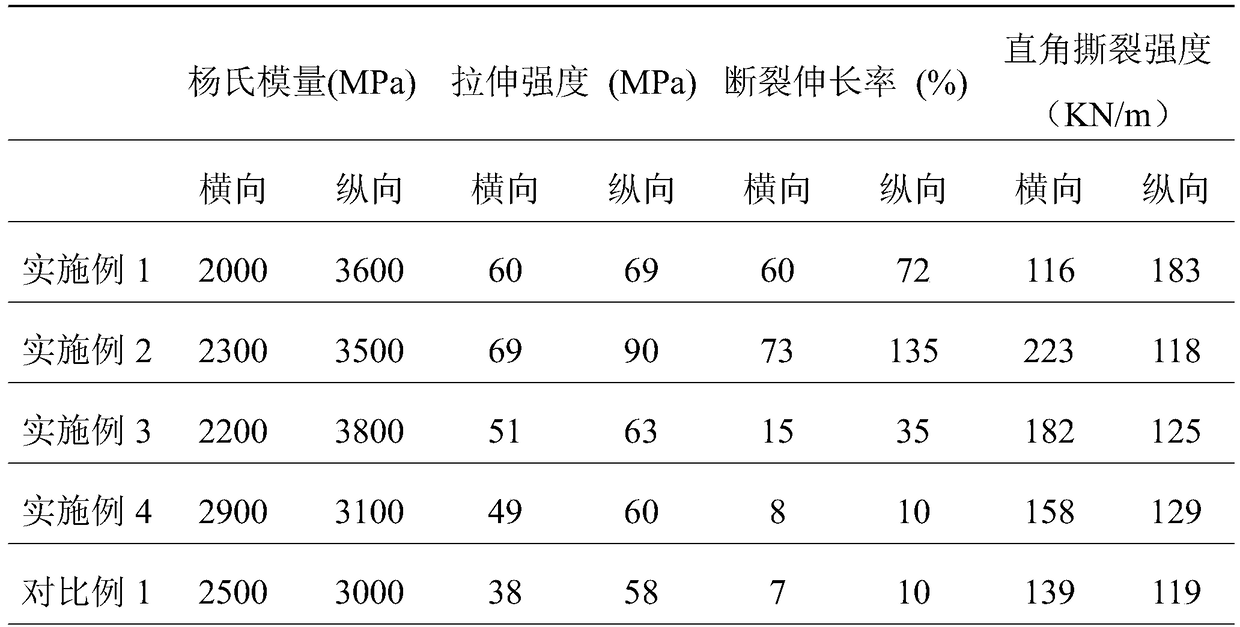

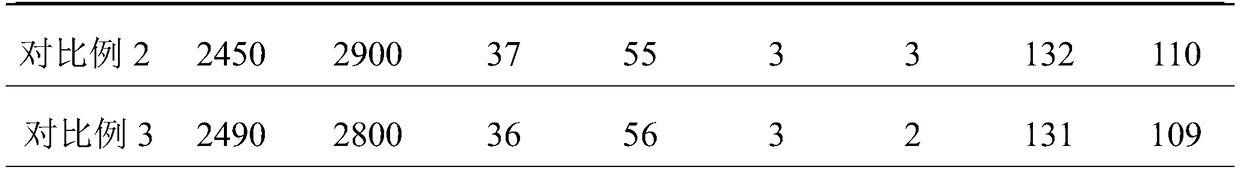

Embodiment 1

[0030] PLA (trade name: Natureworks 2002D, D-type lactic acid unit content: 4%, weight average molecular weight: 121,000 g / mol) was placed in a vacuum oven at 70° C. for 24 hours under vacuum. Then it was annealed at 110°C for 5 hours to make the cold crystallization complete, and the crystallized polylactic acid was obtained, and the crystallized polylactic acid was blown into a film by a film blowing machine. Zone: 155°C, Zone 3: 155°C, Zone 4: 155°C, the screw speed of the main engine is 200rpm, the traction ratio is 8.6, and the inflation ratio is 2.7. The mechanical properties of the films were tested, and the test results are listed in Table 1.

Embodiment 2

[0032] PLA (trade name: Natureworks 2003D, D-type lactic acid unit content 4.1%, weight average molecular weight 180000 g / mol) was placed in a vacuum oven at 70° C. for 24 hours under vacuum. Add PLA to the twin-screw extruder, and the extrusion and granulation conditions are as follows: the set temperature of the twin-screw extruder is: Zone 1: 177°C, Zone 2: 183°C, Zone 3: 184°C, Zone 4: 185°C, zone 5: 185°C, zone 6: 185°C, zone 7: 184°C, zone 8: 183°C, head: 181°C, screw speed 200rpm, polylactic acid pellets were obtained after extrusion granulation and drying , the pellets were annealed at 105°C for 5 hours to make the cold crystallization complete, and the crystallized polylactic acid was obtained, and the crystallized polylactic acid was blown into a film by a blown film machine. The setting conditions of the blown film machine were: Zone 1: 155°C , Zone 2: 155°C, Zone 3: 155°C, Zone 4: 155°C, the screw speed of the main engine is 200rpm, the traction ratio is 8.6, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com