Method for producing polyurethane toughness-reinforcing cast form nylon composite material

A technology for casting nylon and composite materials, which is applied in the field of preparation of polyurethane toughened casting nylon composite materials, can solve problems such as easy brittle cracking, large brittleness, and application field limitations, and achieve high mechanical strength, improved mechanical strength, friction The effect of improving the chemical properties and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

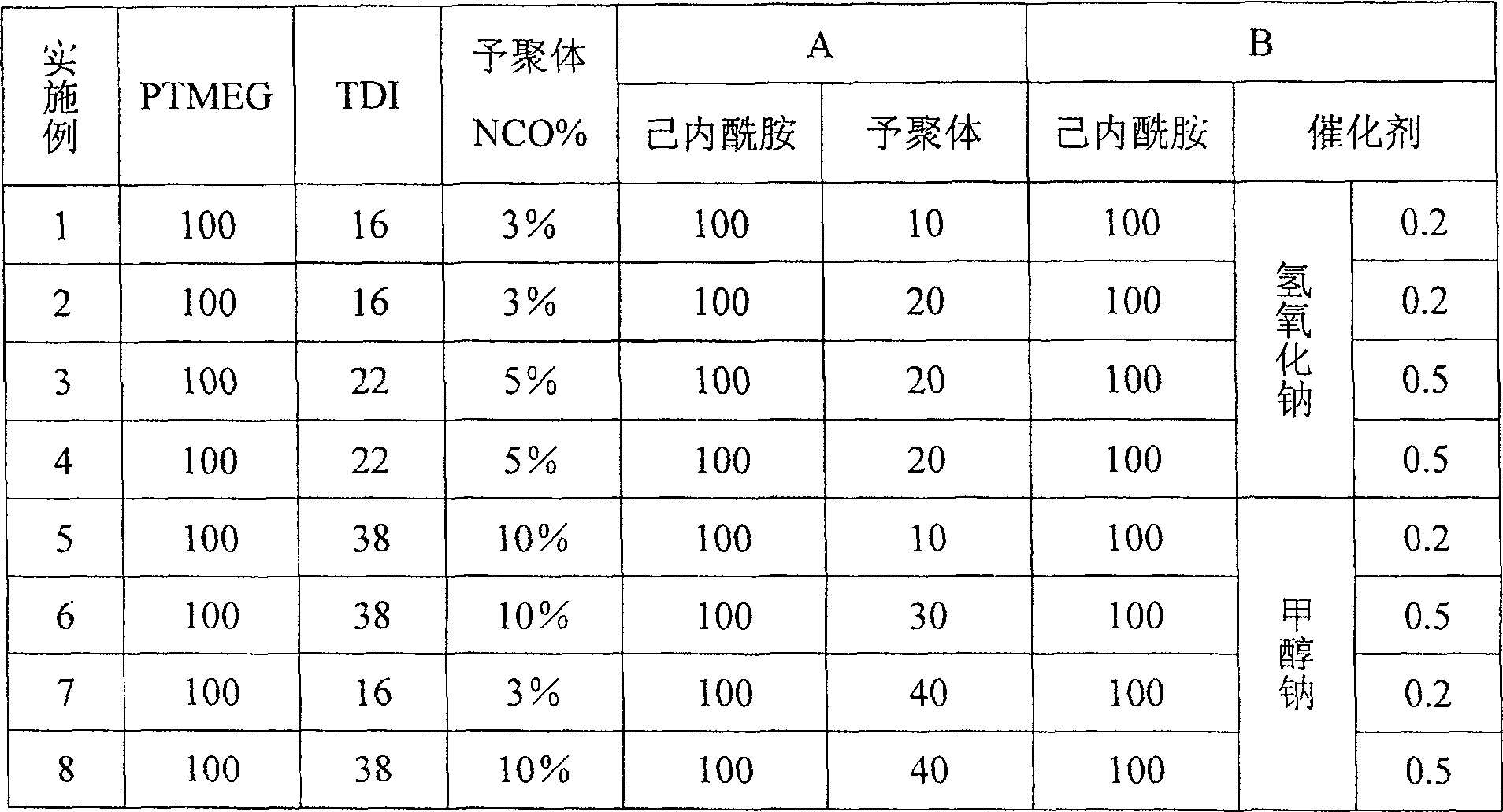

Examples

Embodiment 1

[0016] (1) Preparation of isocyanate-terminated polyurethane prepolymer:

[0017] A) Weigh 100 parts of polytetrahydrofuran ether (abbreviated as PTMG) in parts by mass (hereinafter all in parts by mass), and dehydrate at 100°C-150°C and 0.01-0.1Pa pressure for 30-60min. Get the processed polyether, standby;

[0018] B) 16 parts of toluene diisocyanate (abbreviated as TDI) are weighed for subsequent use;

[0019] C) Heating the treated PTMG to 70° C., adding metered TDI to carry out polymerization reaction, and reacting for 120-240 minutes to obtain an isocyanate-terminated polyurethane prepolymer with a free isocyanate content of 3%. spare;

[0020] (2) Weigh 200 parts of caprolactam monomer, divide one-half into a container and heat to about 120°C to melt the material, vacuumize and dehydrate until no water flows out, and the vacuum degree is 10 -1 ~10 -3 Pa. spare;

[0021] (3) Mix 100 parts of (2) dehydrated caprolactam liquid with 10 parts of polyurethane prepolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com