Coextrusion-lamination obstructing packaging film

A technology of co-extruded composite and packaging film, applied in the field of co-extruded packaging film and co-extruded composite barrier packaging film, which can solve the problem that the co-extrusion ductility and EVOH barrier property of barrier layer cannot be achieved simultaneously. It can reduce and shorten the effective shelf life of products, so as to delay the phenomenon of oxidative deterioration, prolong the shelf life of products, and prevent water loss and drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

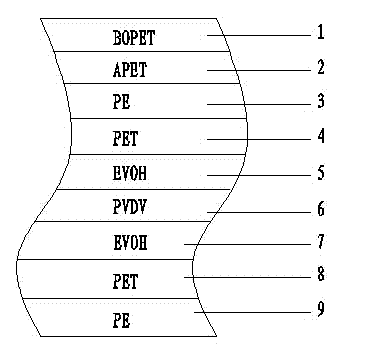

[0015] like figure 1 As shown, the co-extruded composite barrier packaging film of the present invention includes a BOPET biaxially oriented polyester film 1, an APET light-shielding film 2, a first PE polyethylene film 3, a first PET polyester film 4, a first EVOH barrier layer 5. PVDC gas barrier film 6, the second EVOH barrier layer 7, the second PET polyester film 8 and the second PE polyethylene film 9; the BOPET biaxially stretched polyester film 1, APET light-shielding film 2, the first PE polyethylene film 3, first PET polyester film 4, first EVOH barrier layer 5, PVDC gas barrier film 6, second EVOH barrier layer 7, second PET polyester film 8 and second PE polyethylene film 9 Co-extruded from the outside to the inside to form a packaging film. Mesh holes are processed on the first PET polyester film 4 and the second PET polyester fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com