Aqueous coating agent and gas barrier film

A technology of water-based coating agent and gas-barrier laminate, which can be applied in the direction of coating, polyurea/polyurethane coating, type of packaging items, etc., can solve the problems of inability to confirm the content, peeling of laminated film, reduction of lamination strength, etc., Good adhesion or cohesion, improved quality retention, and excellent gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

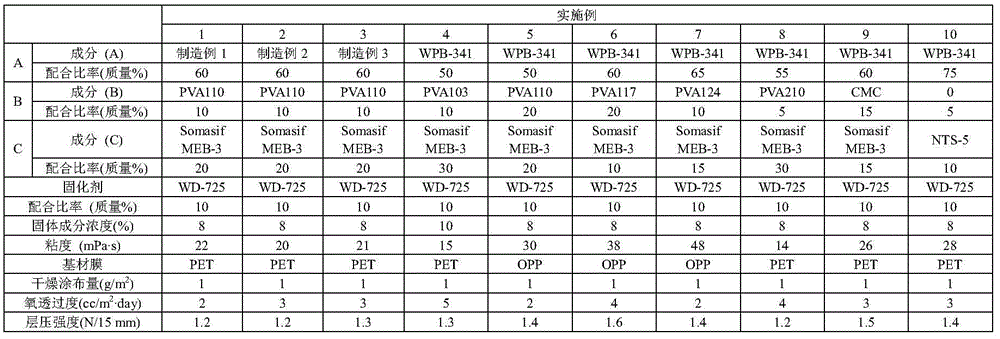

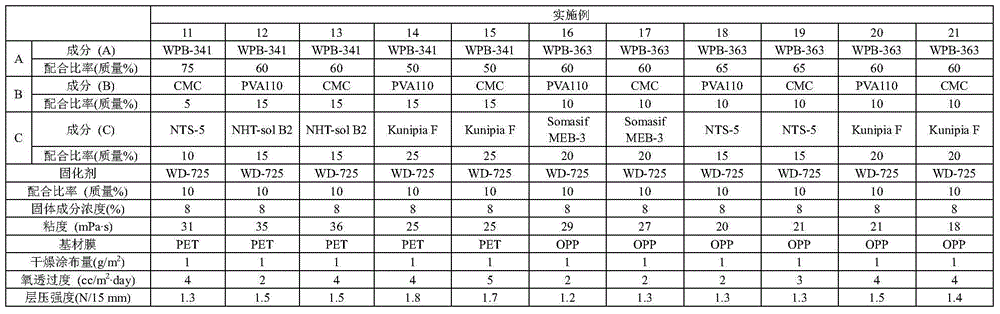

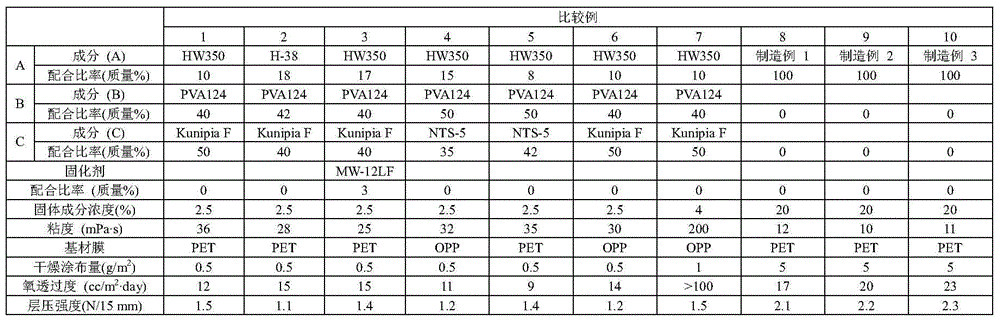

[0189] Hereinafter, the present invention will be described more concretely through examples and comparative examples, but the present invention is not limited to the following examples.

[0190] Hereinafter, the first embodiment and the second embodiment of the present invention will be more specifically described by way of examples and comparative examples.

manufacture example 1

[0192] 45.5 g of mXDI (m-xylylene diisocyanate), 93.9 g of hydrogenated XDI (1,3-bis(isocyanate methyl) cyclohexane), 24.8 g of ethylene glycol, 13.4 g of dimethylol propionic acid and 80.2 g of methyl ethyl ketone was mixed as a solvent, and reacted at 70° C. for 5 hours under a nitrogen atmosphere to prepare a carboxyl group-containing urethane prepolymer solution.

[0193] Next, this carboxyl group-containing urethane prepolymer solution was neutralized with 9.6 g of triethylamine at 40°C.

[0194] Disperse the carboxyl group-containing urethane prepolymer solution in 624.8 g of water with a homodisperser, perform chain extension reaction with 21.1 g of 2-[(2-aminoethyl)amino]ethanol, and distill off methyl ethyl ketone , thereby obtaining a water-dispersible polyurethane resin having an acid group having a solid content of 25% by mass, an average particle diameter of 90 nm, and an acid value of 26.9 mgKOH / g.

[0195] Next, using γ-(2-aminoethyl)aminopropylmethyldimethoxys...

manufacture example 2

[0197] Except having changed the polyamine compound of manufacture example 1 into the following compound, it carried out similarly to manufacture example 1, and obtained the water-based polyurethane resin of manufacture example 2.

[0198] Polyamine obtained by adding 97.1 g of hydrogenated XDI (1,3-bis(isocyanatemethyl)cyclohexane) dropwise, mixing 93.6 g of dimethylethanolamine, and reacting at 60°C for 2 hours under a nitrogen atmosphere compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com