Gas barrier film

A technology of gas barrier property and gas barrier layer, applied in the field of gas barrier film, which can solve the problems of gas barrier layer defects and inability to stably obtain high gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

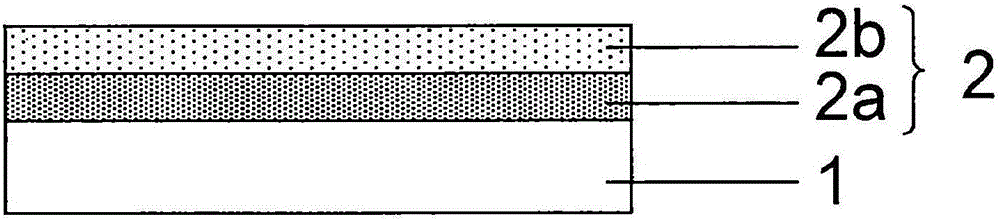

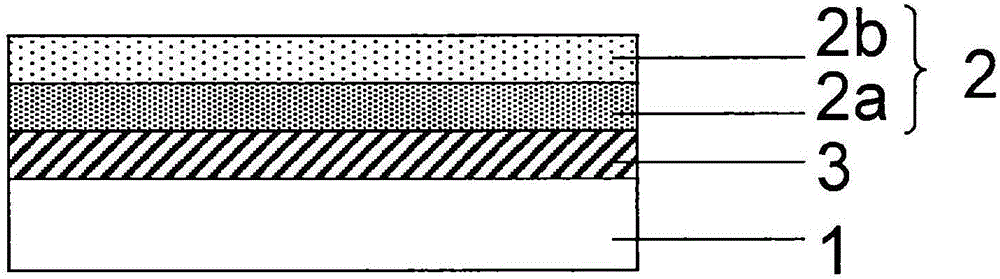

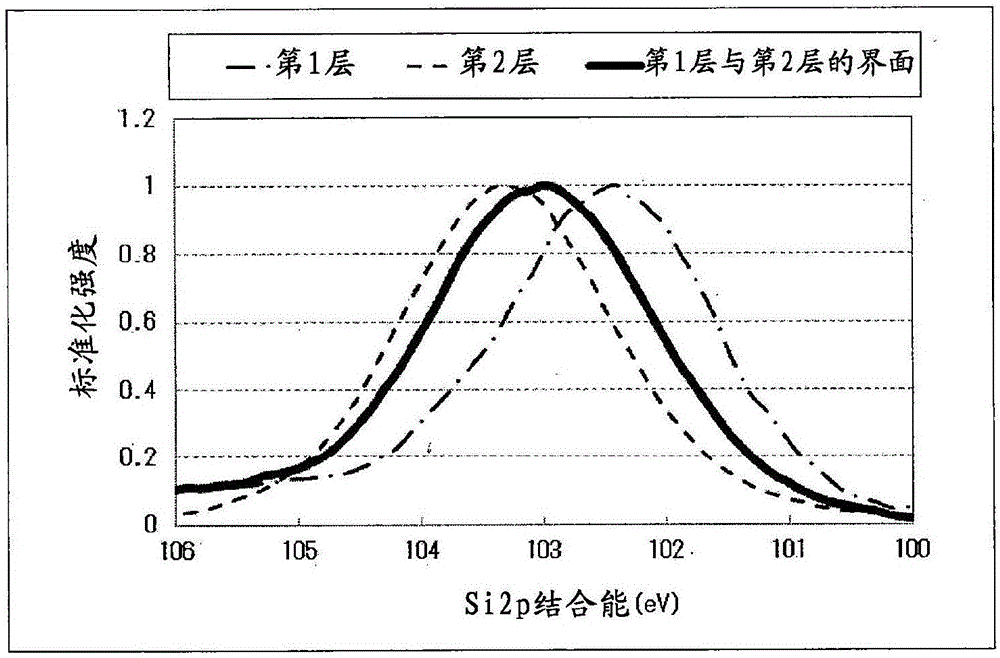

Method used

Image

Examples

Embodiment 1

[0133] (formation of layer 1)

[0134] As the polymer substrate 1, a polyethylene terephthalate film ("Lumila" (registered trademark) U48 manufactured by Toray Co., Ltd.) with a thickness of 50 μm was used.

[0135] use Figure 5 The shown winding type sputtering-chemical vapor deposition device 4 (hereinafter simply referred to as sputtering-CVD device) is provided with a sputtering target as a mixed sintered material formed of zinc oxide, silicon dioxide and aluminum oxide. The sputter electrode 11 is sputtered with argon and oxygen, and ZnO-SiO is provided as the first layer on the surface of the polymer substrate 1. 2 -Al 2 o 3 layer so that the film thickness becomes 150 nm.

[0136] The specific operation is as follows. First, a sintered sputtering target having a composition mass ratio of zinc oxide / silicon dioxide / alumina of 77 / 20 / 3 was set on the sputtering electrode 11 of the sputtering-CVD apparatus 4 . On the unwinding roll 6 in the winding chamber 5 of the s...

Embodiment 2

[0145] (Synthesis of Polyurethane Compounds with Aromatic Ring Structure)

[0146]Into a 5-liter 4-neck flask, 300 parts by mass of bisphenol A diglycidyl ether acrylic acid adduct (manufactured by Kyoeisha Chemical Co., Ltd., trade name: Epoxy Ester 3000A) and 710 parts by mass of ethyl acetate were added, and It heated so that internal temperature might become 60 degreeC. 0.2 parts by mass of di-n-butyltin dilaurate was added as a synthesis catalyst, and 200 parts by mass of dicyclohexylmethane 4,4'-diisocyanate (manufactured by Tokyo Chemical Industry Co., Ltd.) was added dropwise over 1 hour while stirring. After completion of the dropwise addition, the reaction was continued for 2 hours, and then 25 parts by mass of diethylene glycol (manufactured by Wako Pure Chemical Industries, Ltd.) was added dropwise over 1 hour. After the dropwise addition, the reaction was continued for 5 hours to obtain a polyurethane compound having an aromatic ring structure with a weight avera...

Embodiment 3

[0157] Set ZnO-SiO as layer 1 2 -Al 2 o 3 A gas barrier film was obtained in the same manner as in Example 2 except that the thickness of the layer was 450 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com