Preparation method of nanometer organic modified zirconium phosphate/MC nylon composite material

A technology of nylon composite materials and organic zirconium phosphate, which is applied in the field of MC nylon composite materials, can solve undiscovered problems and achieve the effects of reducing flocculation, large layer spacing, and improving moisture resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

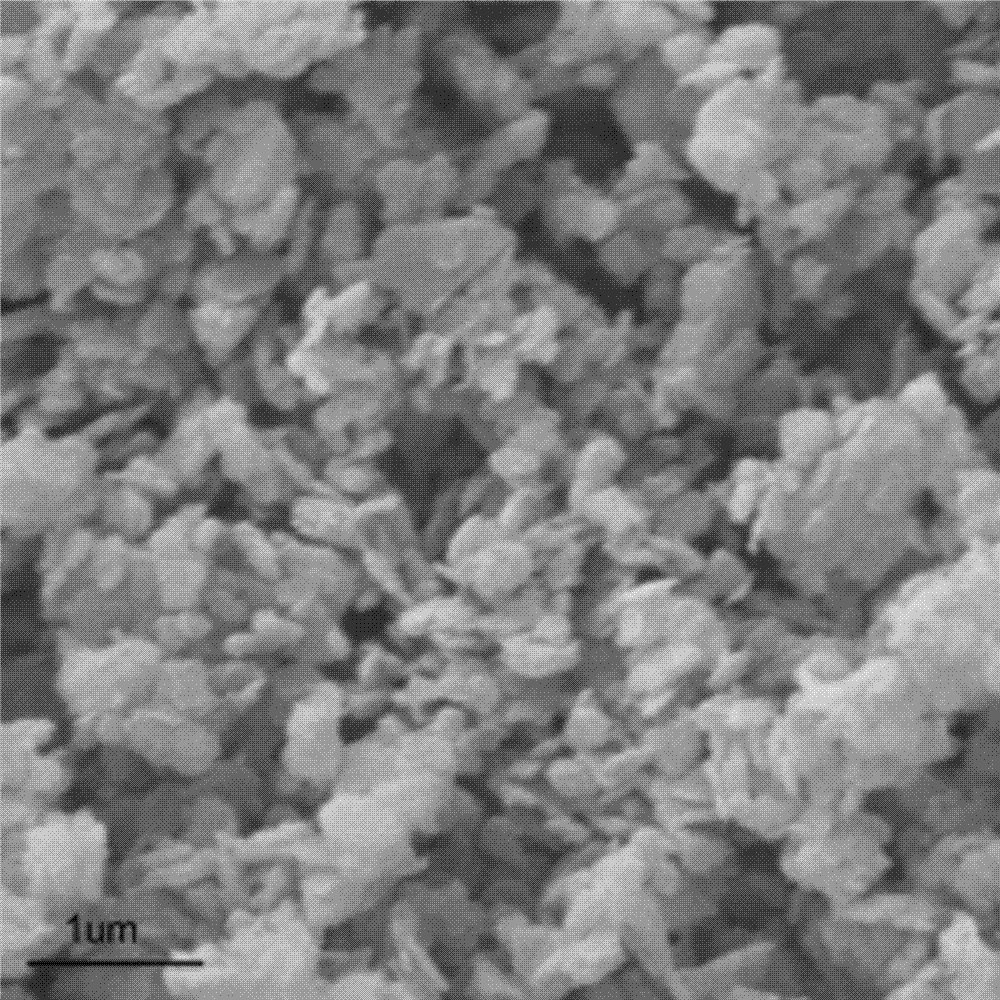

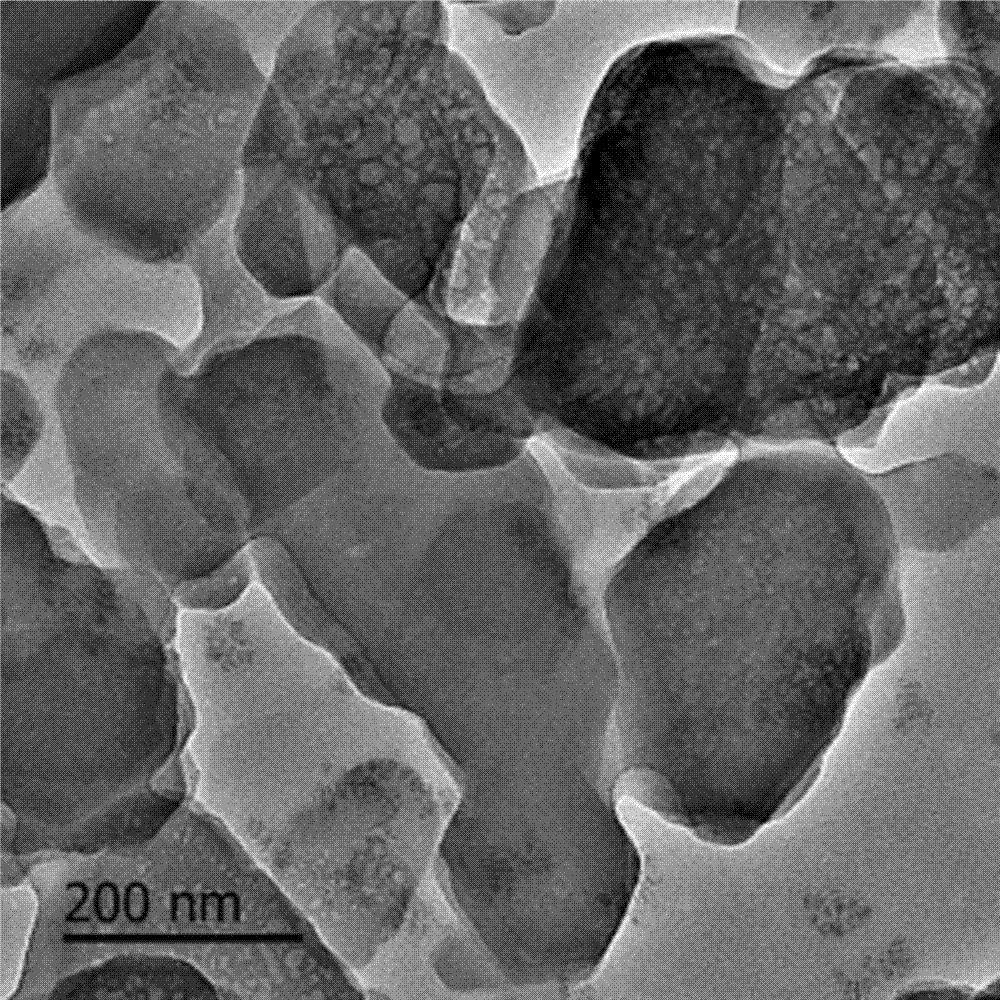

Image

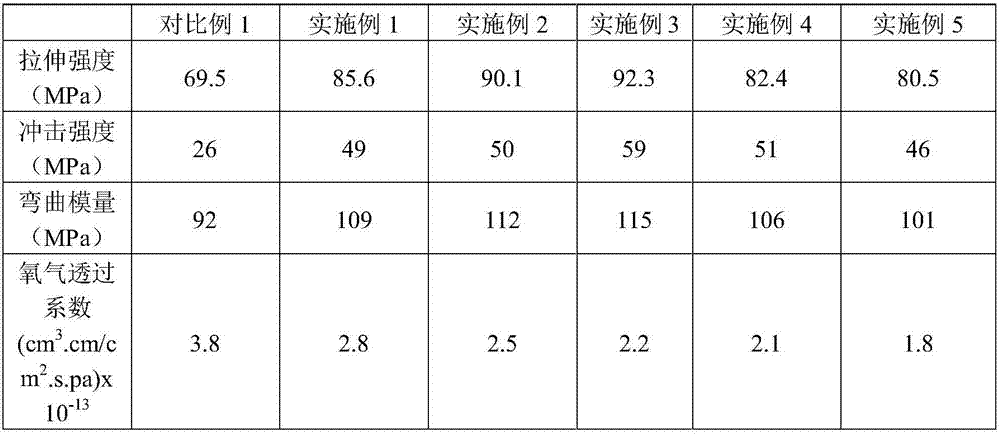

Examples

Embodiment 1

[0033] (1) Preparation of zirconium organophosphate:

[0034] S1. Add 10g ZrOCl in the reaction flask 2 ·8H 2 O, 10g NaF and 100mL distilled water, after stirring and dissolving, add 50mL of 85wt% H 3 PO 4 , exhaust the air in the reaction bottle and then introduce N 2 , Electromagnetic stirring at 25°C continued the reaction for 196h, high-speed centrifugation to separate the precipitate, repeated washing with distilled water until the pH value was neutral, vacuum drying at 60°C and grinding to obtain α-zirconium phosphate powder, and its CEC (cation exchange capacity) was measured It is 195mmol / 100g, and the interlayer distance is 0.76nm.

[0035] S2. Weigh 4.0g of the α-zirconium phosphate powder prepared in step S1, disperse it in 100mL of deionized water, then add 0.1CEC of n-butylamine dropwise for pre-strut, stir and react in a constant temperature water bath at 40°C for 6h, and then continue to drop Add 0.9CEC of ethylene bis(dodecyldimethylammonium chloride) to c...

Embodiment 2

[0041] (1) Preparation of zirconium organophosphate:

[0042] S1. is the same as embodiment 1;

[0043] S2. Weigh 10g of the α-zirconium phosphate powder prepared in step S1, disperse it in 250mL of deionized water, and then add 0.2CEC of n-butylamine dropwise for pre-strutting, stir and react in a constant temperature water bath at 40°C for 6h, and then continue to add dropwise 0.8CEC of ethylene bis(tetradecyldimethylammonium chloride) was chemically modified, and the reaction was continued for 24h under the condition of stirring in a constant temperature water bath at 50°C. The precipitate was separated by high-speed centrifugation, washed by centrifugation with 50% (v / v) ethanol solution and deionized water respectively, vacuum-dried at 60° C., and ground to obtain an organic zirconium phosphate sample. The interlayer distance of modified zirconium phosphate is 3.30nm calculated by XRD detection and Bragg formula.

[0044] (2) Preparation of zirconium organophosphate / MC ...

Embodiment 3

[0049] (1) Preparation of zirconium organophosphate:

[0050] S1. is the same as embodiment 1;

[0051] S2. Weigh 100g of the α-zirconium phosphate powder prepared in step S1, disperse it in 2500mL of deionized water, then add 0.3CEC of n-butylamine dropwise for pre-strut, stir and react in a constant temperature water bath at 40°C for 6h, and then continue to add dropwise 0.7CEC of ethylene bis(hexadecyldimethylammonium chloride) was chemically modified, and the reaction was continued for 24 hours under the condition of stirring in a constant temperature water bath at 50°C. The precipitate was separated by high-speed centrifugation, washed by centrifugation with 50% (v / v) ethanol solution and deionized water respectively, vacuum-dried at 60° C., and ground to obtain an organic zirconium phosphate sample. The interlayer distance of modified zirconium phosphate is 2.90nm calculated by XRD detection and Bragg formula.

[0052] (2) Preparation of zirconium organophosphate / MC ny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com