High-transparent high-barrier and easy-taking opening sealing cover membrane and production technology thereof

A high-barrier, sealing cover technology, applied in the direction of layered products, synthetic resin layered products, lamination, etc., can solve the problems of uncontrollable sealing strength, general easy to open performance, general barrier properties, etc., to improve user experience, Solvent-free, excellent moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

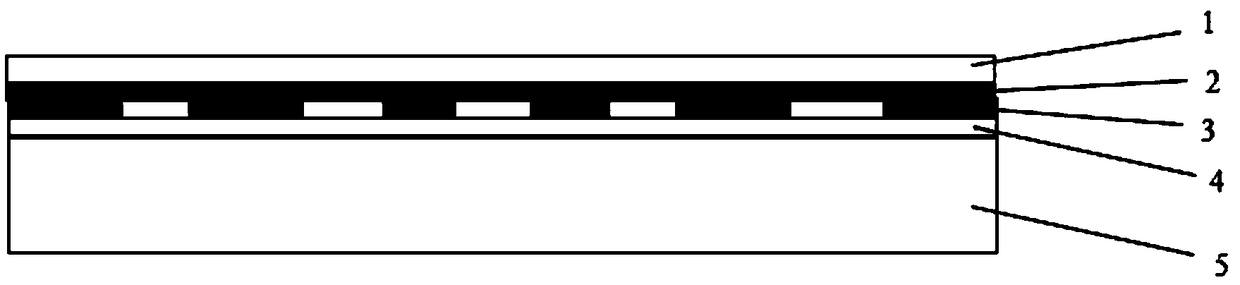

Image

Examples

Embodiment 1

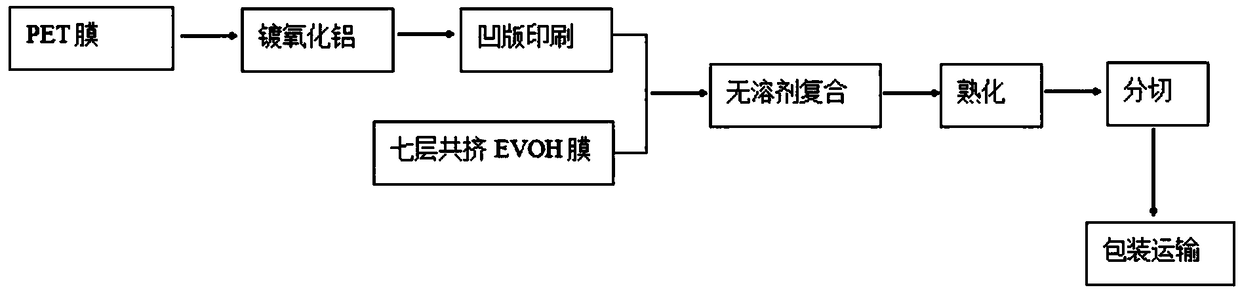

[0048] The production process of the high-transparency, high-barrier and easy-to-open cap film of the present invention comprises the following steps:

[0049] Step 1, use plasma vacuum plating technology to vapor-deposit on the PET film to form a film structure: PET film layer / aluminum oxide layer, and then use gravure printing technology to print ink on the surface of the aluminum oxide layer to form a film structure: PET film layer / Aluminum oxide layer / ink layer.

[0050] The process of plasma vacuum plating technology is as follows: first, install the roll film of PET film base material to be aluminized in the vacuum evaporation machine, use a vacuum pump to evacuate the vacuum in the evaporation chamber to 10Pa, and set the unwinding speed of PET film base material 10±2m / s, unwinding tension 380-450N, the PET film substrate moves to the plasma processor, and the power of the plasma processor is set to 2±1kW; then the PET film substrate reaches the evaporation chamber, an...

Embodiment 2

[0061] Same as Example 1, only adjustments are made on the formula of the film layer, as shown in Table 2 below:

[0062] Table 2

[0063]

Embodiment 3

[0065] Same as Example 1, only adjustments are made on the formula of the film layer, as shown in Table 2 below:

[0066] table 3

[0067]

[0068]

[0069] The properties of the high transparency, high barrier and easy-to-open lid film prepared in the above examples, traditional ethylene-vinyl acetate copolymer EVA composite film (PET / AL / EVA) and elastomer composite film (BOPA / EVOH co-extrusion film / PT1450) The comparison of technical indicators is shown in Table 4 below:

[0070] Table 4

[0071]

[0072] The comparison results of the comprehensive evaluation of the easy-to-remove performance of the high-transparency, high-barrier and easy-to-remove lid film prepared in the above examples with traditional ethylene-vinyl acetate copolymer (EVA) composite films and elastomer composite films are shown in Table 5 below:

[0073] table 5

[0074]

[0075] Compared with other cover materials, the product of the present invention has the characteristics of high trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com