Thermoplastic elastomer composition and pneumatic tire using the same

A thermoplastic elastomer and composition technology, applied in the field of thermoplastic elastomer composition and pneumatic tires, can solve the problems of reducing tire weight, fuel economy obstacles, etc., and achieve the effect of excellent gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

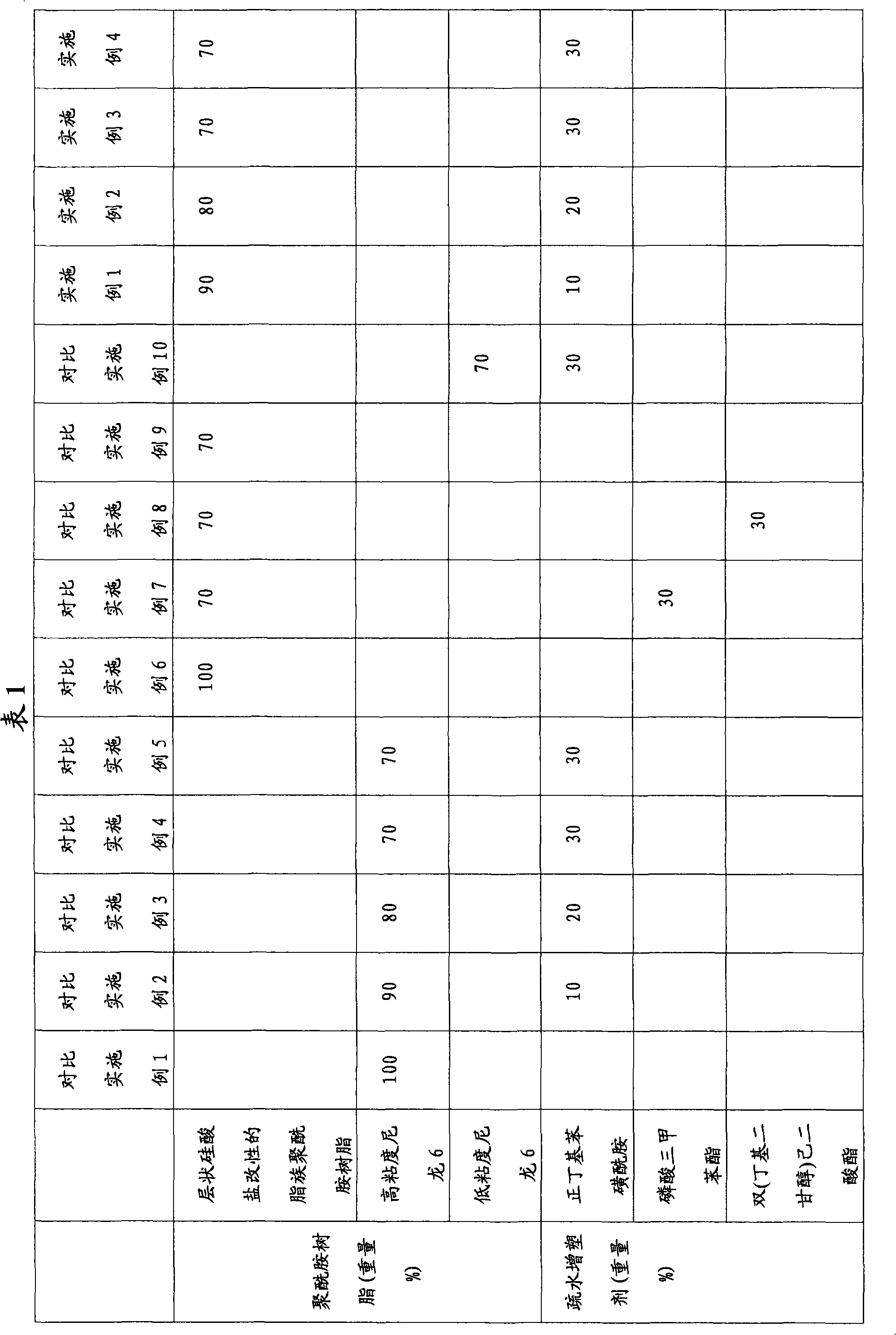

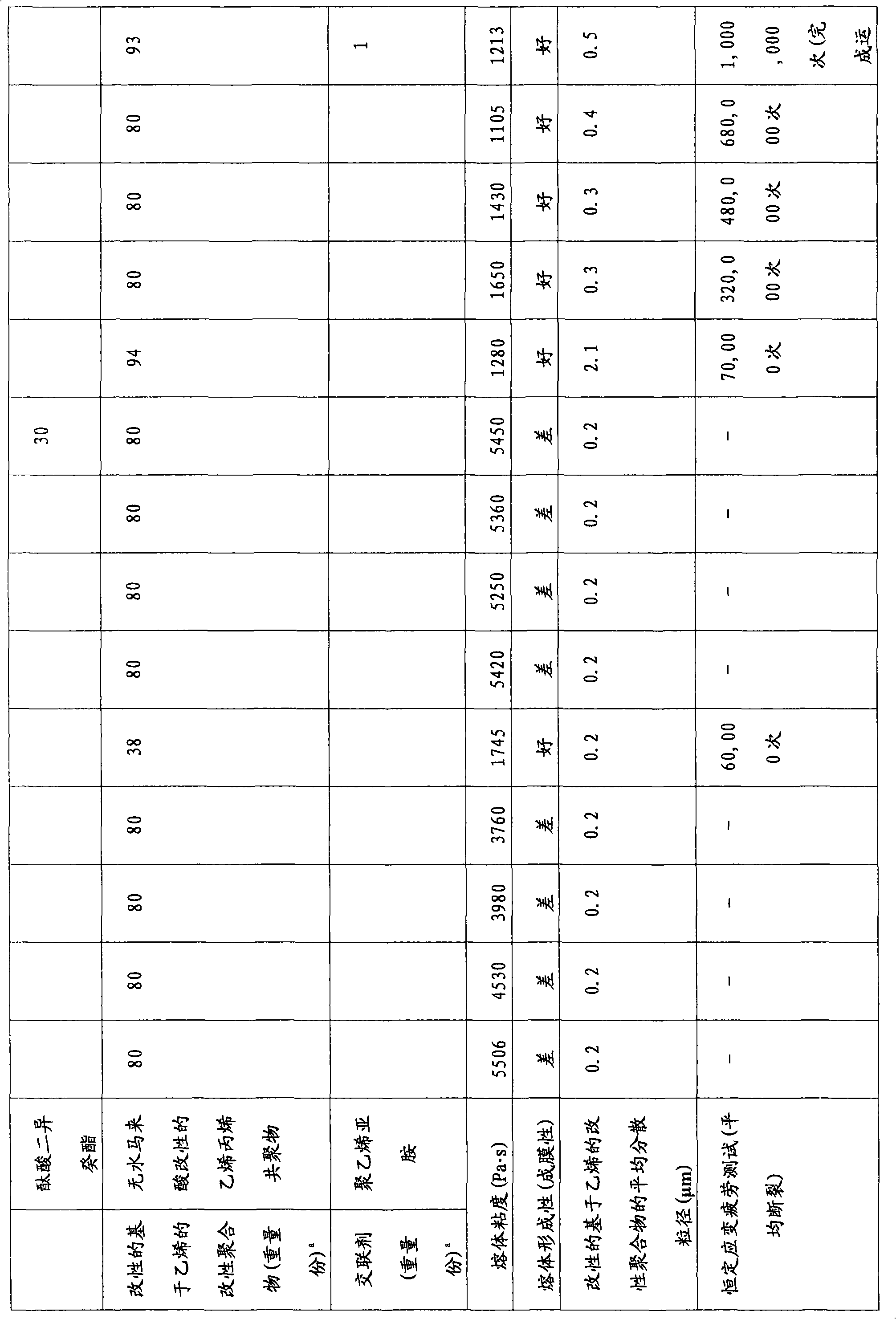

[0046] (1) Main components

[0047] The following three types are used as polyamide resins.

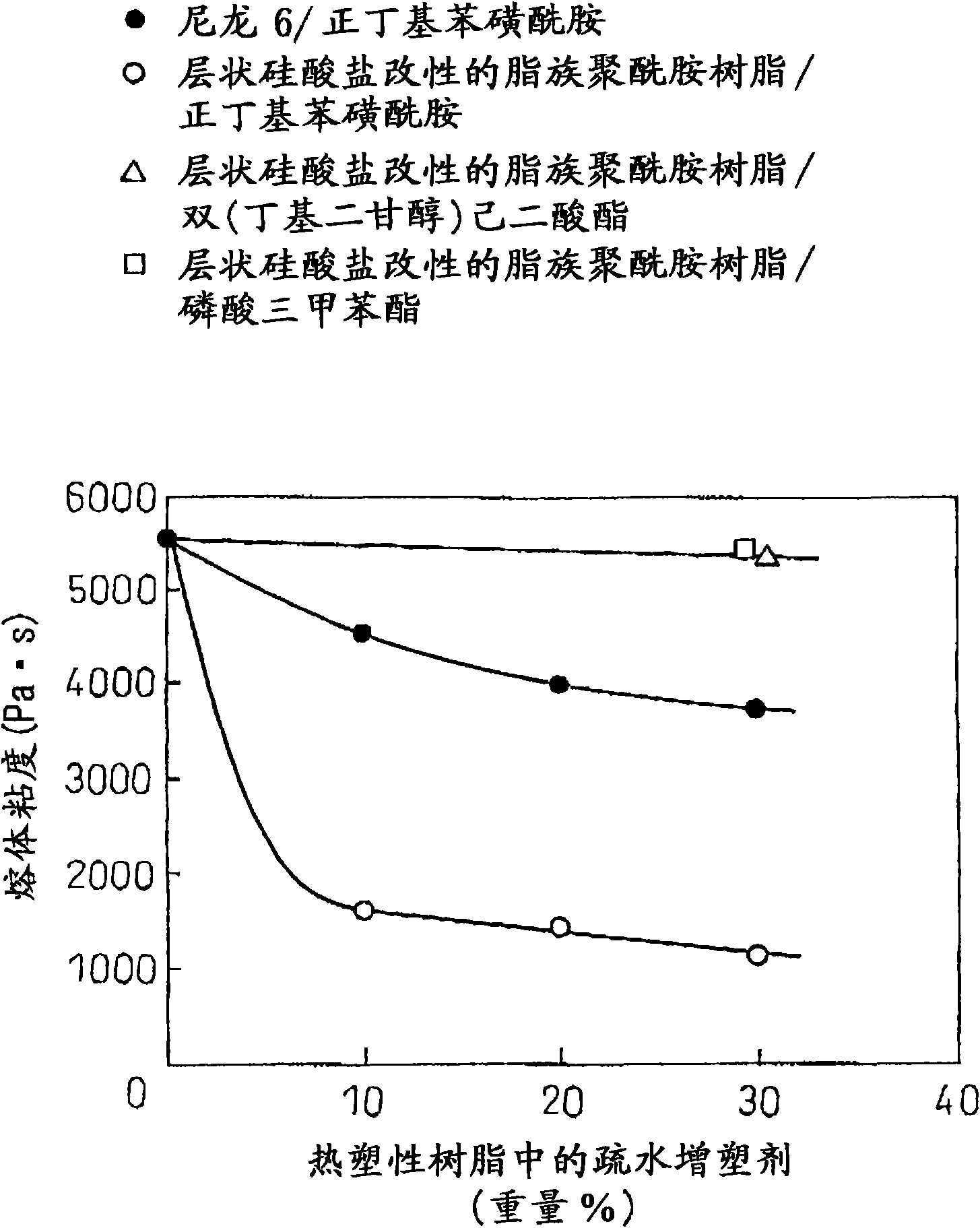

[0048] Polyamide resin 1: layered silicate-modified aliphatic polyamide resin prepared by interlayer polymerization (Nylon 6 "UBE Nylon" 1022C2 produced by Ube Industries, Ltd.; layered silicate: sodium montmorillonite stone; phyllosilicate content: 2% by weight; melt viscosity η: 387Pa·S)

[0049] Polyamide resin 2: high-viscosity nylon 6 (nylon 6 "UBE nylon" 1022B produced by Ube Industries, Ltd.; melt viscosity η: 254Pa·S)

[0050] Polyamide resin 3: low-viscosity nylon 6 (nylon 6 "UBE nylon" 1013B produced by Ube Industries, Ltd.; melt viscosity η: 113 Pa·S)

[0051] The following four types are used as hydrophobic plasticizers.

[0052] Hydrophobic plasticizer 1: n-butylbenzenesulfonamide (BM-4 produced by Daihachi Chemical Industry Co., Ltd.; SP value: 10.5 (cal / cm 2 ) 1 / 2 )

[0053] Hydrophobic plasticizer 2: tricresyl phosphate (TCP produced by Daihachi Chemical Industry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com