Composite gas barrier laminate and method for producing same, and composite electrode

A laminated body and gas barrier technology, which is applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as performance degradation, and achieve softness, flexibility, good gas barrier properties, and excellent curl effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

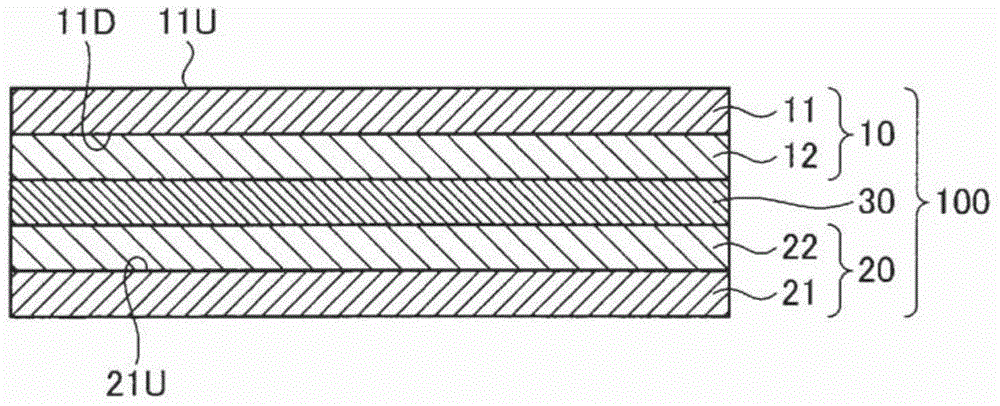

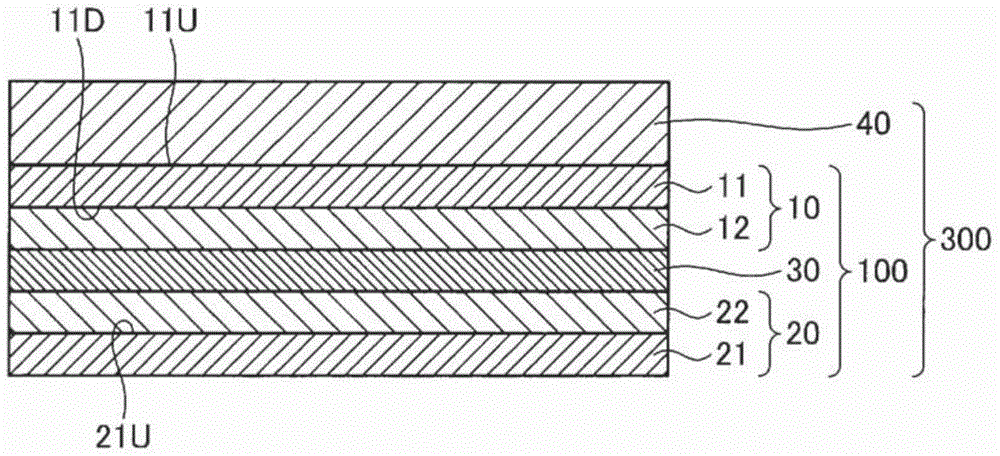

[0212] A roll-shaped alicyclic polyolefin resin film (a film containing a norbornene polymer, "ZeonorFilm ZF16" manufactured by Zeon Co., Ltd., 100 μm in thickness) was drawn out, and SiN with a thickness of 100 nm was formed on one side of the film by a sputtering device. film to obtain a gas barrier laminate (A). The obtained gas barrier laminate (A) had curls with a curl amount of 4 mm.

[0213] Furthermore, a gas barrier laminate (B) was produced in the same manner as the above-mentioned gas barrier laminate (A).

[0214] In addition, a film formed of a styrene-isoprene-styrene copolymer having a thickness of 100 μm was prepared as a thermoplastic elastomer film. The above-mentioned styrene-isoprene-styrene copolymer is an aromatic vinyl compound-conjugated diene compound produced by using styrene as an aromatic vinyl compound and isoprene as a chain conjugated diene compound. The polymer obtained by hydrogenating the block copolymer and further modifying it with an alkoxy...

Embodiment 2

[0221] A roll-shaped alicyclic polyolefin resin film (a film containing a norbornene polymer, "ZeonorFilm ZF16" manufactured by Zeon Co., Ltd., 100 μm in thickness) was drawn out, and a film with a thickness of 1 μm was formed on one surface using a plasma CVD apparatus. SiOC film to obtain a gas barrier laminate (A). The obtained gas barrier laminate (A) had curls with a curl amount of 15 mm.

[0222] Furthermore, a gas barrier laminate (B) was produced in the same manner as the above-mentioned gas barrier laminate (A).

[0223] In addition, the same thermoplastic elastomer film as in Example 1 was prepared.

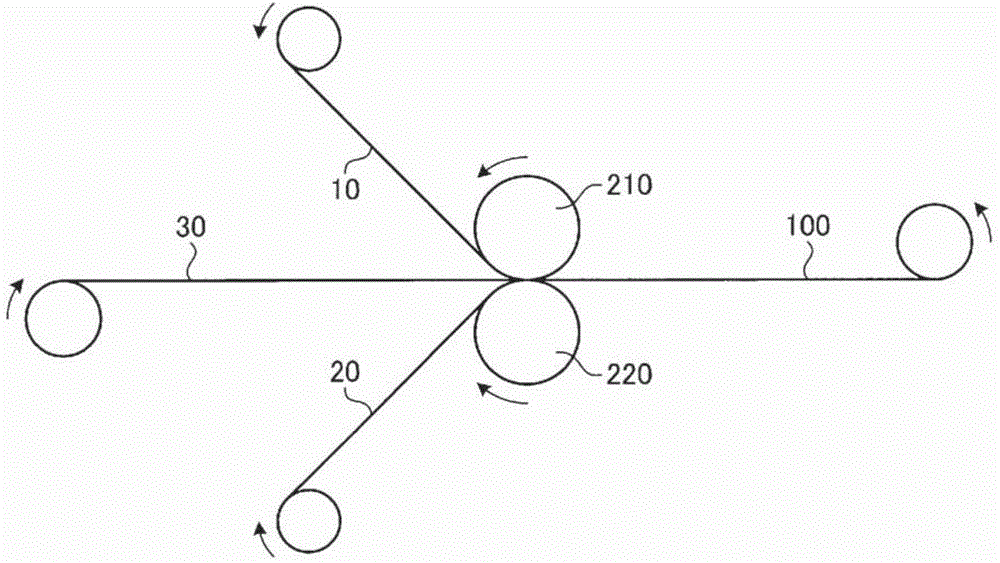

[0224] The gas barrier laminate (A) and the gas barrier laminate (B) were disposed so that the SiOC films faced each other, and a thermoplastic elastomer film was sandwiched between them. On one side, the laminated gas barrier laminate (A), thermoplastic elastomer film, and gas barrier laminate (B) were pressed from both sides with a pair of opposing resin rolls under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com