Egg product freshness keeping method by means of double layers of nano-antibacterial coating films

A coating film preservation and nano-technology, which is applied in the direction of coating protective layer to preserve eggs, etc., can solve the problems of ineffective preservation of eggs, polyvinyl alcohol does not have antibacterial activity, antibacterial preservation performance does not meet the requirements, etc., and achieves good results. The effect of application prospect, environmental friendliness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

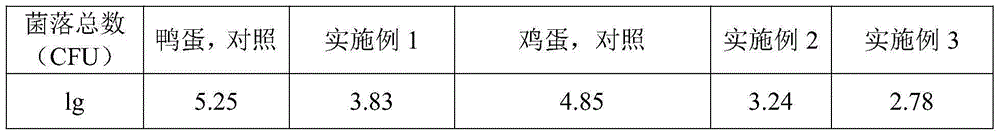

Embodiment 1

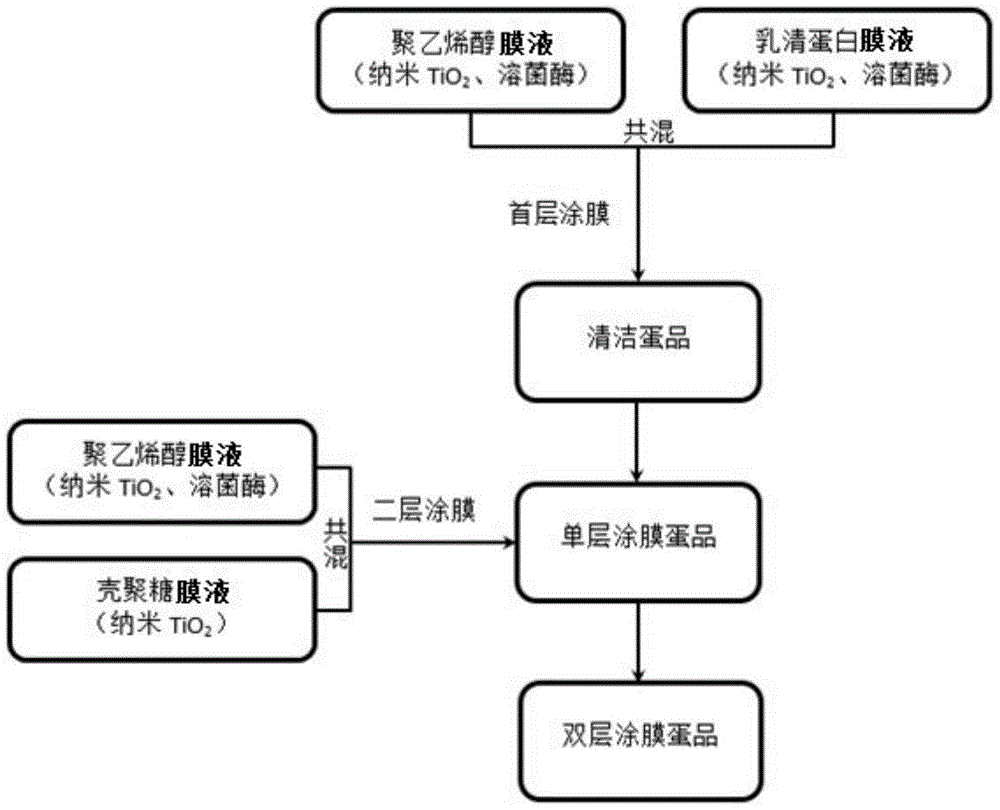

[0046] This embodiment relates to a method for using nanometer double-layer antibacterial coating film to preserve eggs, and its schematic flow chart is as follows: figure 1As shown, it specifically includes the following steps:

[0047] Based on the total mass of the PVA film solution, 2% of PVA was dissolved in distilled water to prepare a solution, 0.4% of glycerin and 0.6% of Tween 80 were added, and stirred for 2 hours in a water bath at 85°C. Add 0.1% nano-TiO after cooling 2 , after homogenization, PVA film liquid is obtained.

[0048] Based on the total mass of the whey protein film solution, 3% protein was dissolved in distilled water to prepare a solution, 0.6% glycerin and 0.9% Tween 80 were added, and stirred in a water bath at 85° C. for 1 hour. Add 0.1% nano-TiO after cooling 2 and 0.2% sodium ethylparaben, homogenized to obtain a whey protein film solution.

[0049] The PVA film solution and the whey protein film solution were stirred and blended at a volume...

Embodiment 2

[0054] This embodiment relates to a method for using nanometer double-layer antibacterial coating film to preserve eggs, and its schematic flow chart is as follows: figure 1 As shown, it specifically includes the following steps:

[0055] Based on the total mass of the PVA film solution, 5% PVA was dissolved in distilled water to prepare a solution, 1.25% glycerin and 2% Tween 80 were added, and stirred in a water bath at 85°C for 2 hours. Add 0.25% nano-TiO after cooling 2 , homogeneously obtained PVA film liquid.

[0056] Based on the total mass of the whey protein film solution, 5% protein was dissolved in distilled water to prepare a solution, 1.25% glycerin and 2% Tween 80 were added, and stirred in a water bath at 85°C for 2 hours. Add 0.25% nano-TiO after cooling 2 and 0.25% sodium ethylparaben, homogenized to obtain a whey protein film solution.

[0057] The PVA film solution and the whey protein film solution were stirred and blended at a volume ratio of 2:1 to fo...

Embodiment 3

[0062] This embodiment relates to a method for using nanometer double-layer antibacterial coating film to preserve eggs, and its schematic flow chart is as follows: figure 1 As shown, it specifically includes the following steps:

[0063] Based on the total mass of the PVA film solution, 6% of PVA was dissolved in distilled water to prepare a solution, 1.8% of glycerin and 3% of Tween 80 were added, and stirred for 4 hours in a water bath at 90°C. Add 0.5% nano-TiO after cooling 2 , homogeneously obtained PVA film liquid.

[0064] Based on the total mass of the whey protein film solution, 6% protein was dissolved in distilled water to prepare a solution, 1.8% glycerin and 3% Tween 80 were added, and stirred for 4 hours in a water bath at 90°C. Add 0.5% nano-TiO after cooling 2 and 0.5% sodium ethylparaben, homogenized to obtain a whey protein film solution.

[0065] The PVA film solution and the whey protein film solution were stirred and blended at a volume ratio of 2:1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com