High-strength fiber reinforcement thin film sealing butt-joint structure universal for high altitude airship

A high-strength fiber and film sealing technology, applied in the direction of rigid spacecraft, can solve the problems of affecting flight height, high radiation intensity, rapid tearing and damage, etc., and achieve the effect of high weight efficiency of airship, simple operation process and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

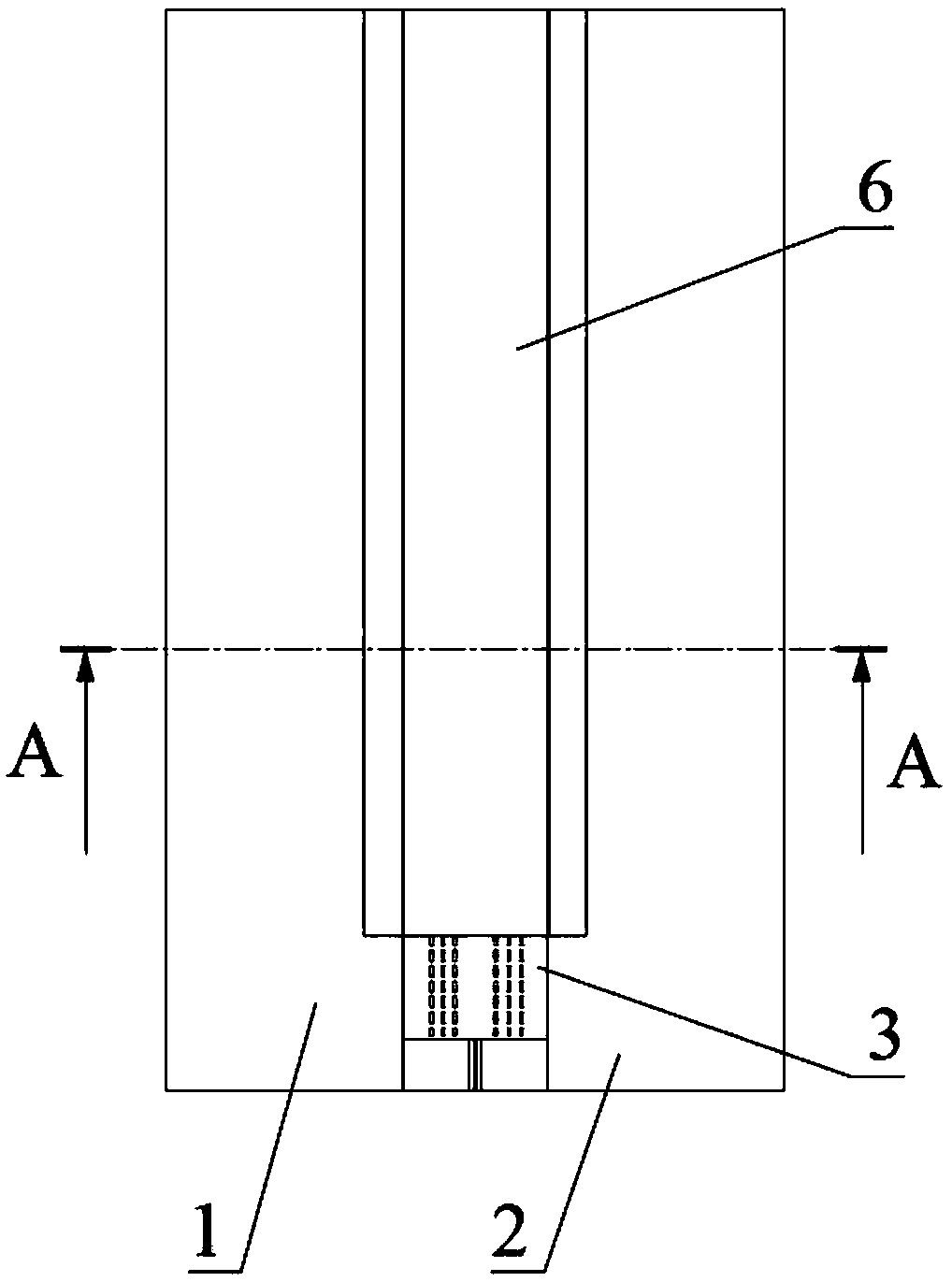

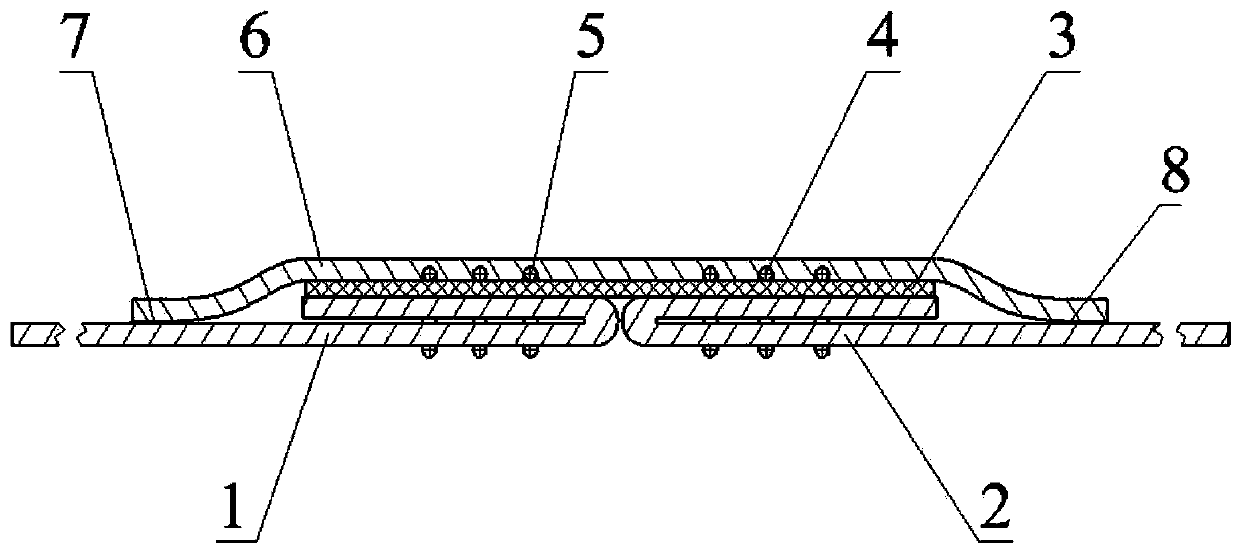

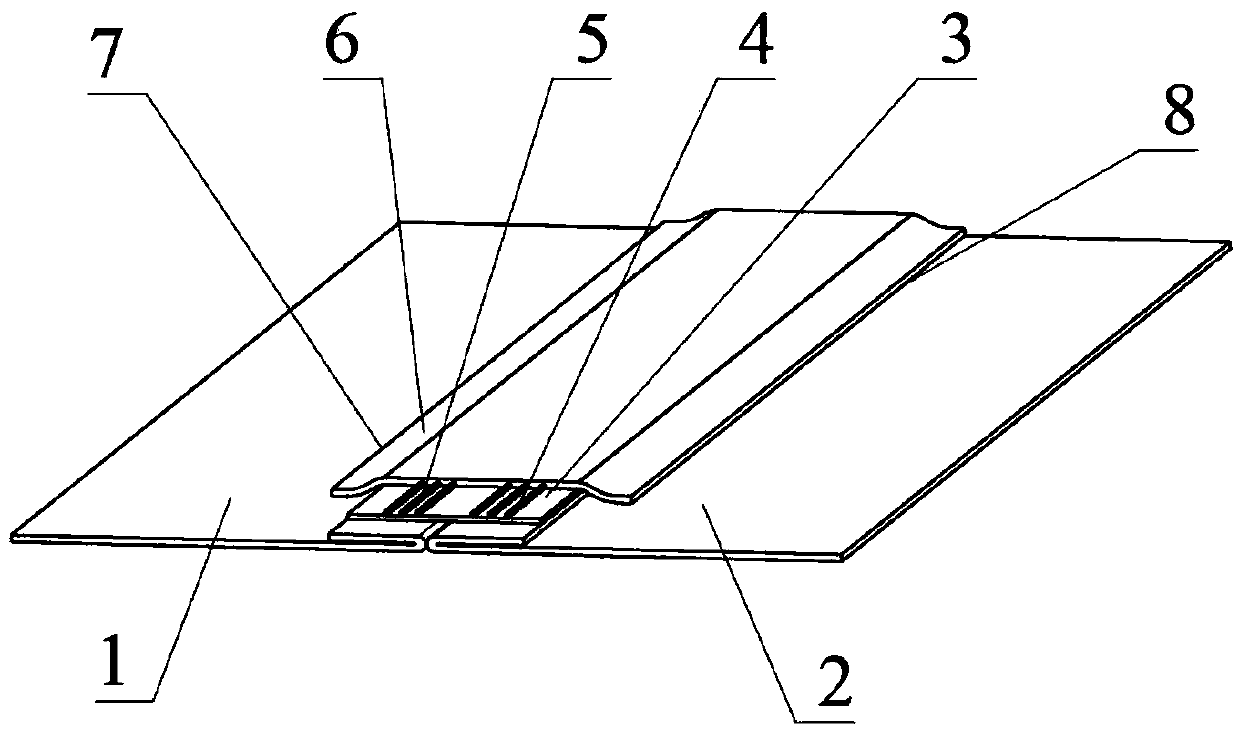

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only schematically illustrate the basic structure of the present invention, and do not involve specific size parameters and performance data, so they only show the structural composition related to the present invention.

[0032] Such as Figure 1 to Figure 3 As shown, a general-purpose high-strength fiber-reinforced film sealing butt joint structure for high-altitude airships, including left and right side docked high-strength fiber-reinforced laminated composite skins, namely the left skin 1, the right skin 2, the middle reinforced bearing layer 3, the left 1. The right side is connected with the sewing thread 4,5, the inner sealing film layer 6, and the left and right side film layer sealing rubber layers 7,8. Before the butt joint processing of the left and right skins 1 and 2 on both sides, the double-fold m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com