Composite layering type wind turbine blade and manufacturing method thereof

A technology for wind turbine blades and a manufacturing method, applied in the field of composite lay-up wind turbine blades and their manufacturing, can solve the problem that the mechanical characteristics of the blade structure are not combined, the strength characteristics of the middle section of the blade cannot be guaranteed, and the mechanical characteristics of the blade cannot be met. problem, to achieve the effect of improving the stiffness of the blade root, the process is convenient to operate, and the processability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

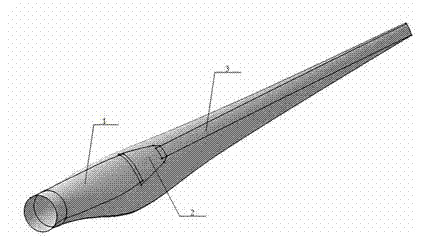

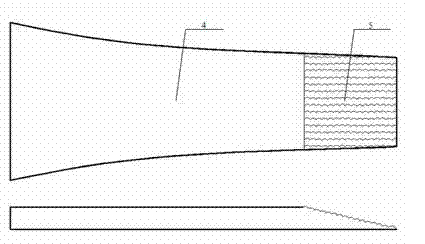

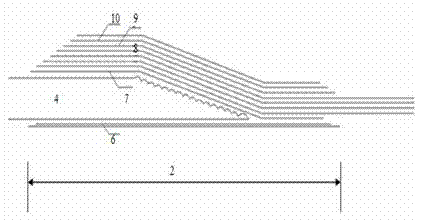

[0021] refer to figure 1 , The wind turbine blade layering type: 1. The main beam layering of the blade root section is bamboo laminated lumber 2. The lapping reinforcement between the bamboo laminated timber at the blade root section and the 0-degree unidirectional fabric from the middle to the tip of the leaf Section 3, the main beam layup of the section from the middle of the blade to the tip of the blade is 0-degree unidirectional cloth. Bamboo laminated lumber with high specific stiffness is used as the laminate material for the main beam of the blade root. The concrete laminate is designed as a laminate with equal thickness and different width. The ply width of the main girder bamboo laminated lumber from the root cylinder section to 1 / 3 of the blade span length decreases smoothly and gradually. This kind of ply can realize the mass production and manufacture of bamboo laminated lumber, and has good manufacturability. The ply material of the main beam from the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com