Film for vacuum heat insulating material, and vacuum heat insulating material

A vacuum heat insulation material and core material technology, which is applied in the direction of heat insulation protection pipelines, thin material processing, heat exchange equipment, etc., can solve the problems of reduced gas insulation performance, and achieve no reduction in heat insulation performance, high reliability, Excellent gas barrier effect

Inactive Publication Date: 2012-09-12

OKURA IND

View PDF4 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, the film for a vacuum heat insulating material obtained by laminating a conventional film on a protective layer has a problem in that the gas barrier property decreases after being bent or deformed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

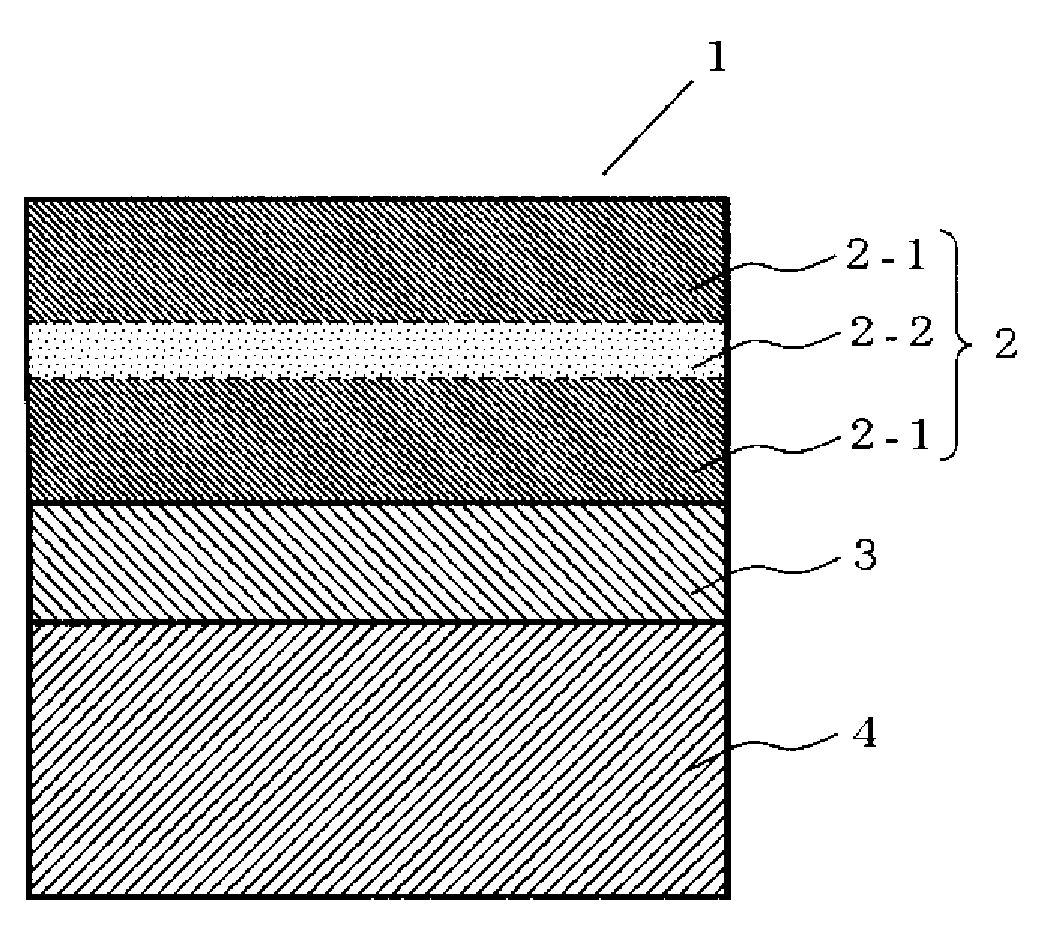

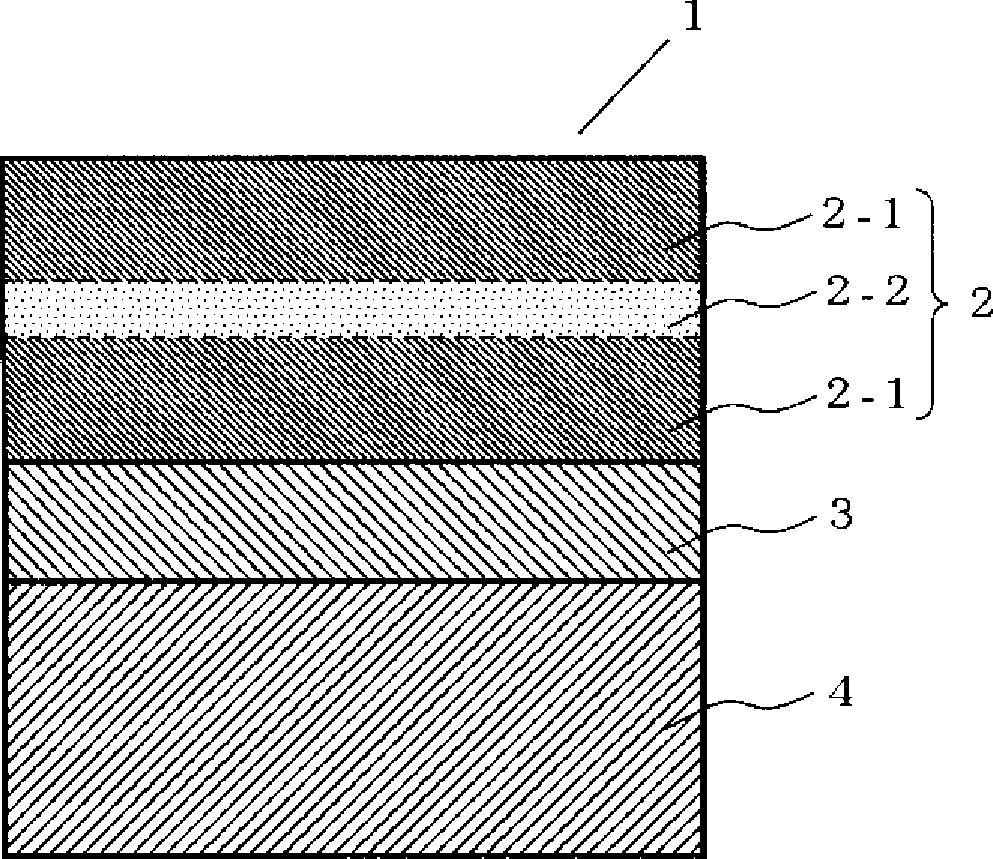

[0044] The protective layer is a co-extruded stretch film with a thickness of 15 μm consisting of nylon-based resin (6 μm) / EVOH (3 μm) / nylon-based resin (6 μm), the gas barrier layer is aluminum foil with a thickness of 6.5 μm, and the heat-sealing layer is 50 μm thick These linear low-density polyethylene films were sequentially laminated and bonded using a urethane-based adhesive to obtain a film for a vacuum heat insulating material.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

Provided are a film for a vacuum heat insulating material, said film being superior in gas barrier properties to the existing films for vacuum heat insulating materials and capable of sustaining the excellent gas barrier properties even after folding or deforming, and a vacuum heat insulating material wherein a core material is hermetically sealed and packaged in said film. The film for a vacuum heat insulating material is characterized by comprising a protective layer formed of a co-extruded and stretched film, which is composed of a nylon-based resin, an ethylene / vinyl alcohol copolymer and a nylon-based resin being layered in this order, a gas barrier layer, and a heat-fusible layer.

Description

technical field [0001] The present invention relates to a film for a vacuum heat insulating material and a vacuum heat insulating material. Background technique [0002] In recent years, from the viewpoint of protecting the global environment, especially energy saving, people have demanded materials with excellent thermal insulation performance. In this regard, vacuum insulation materials have particularly excellent thermal insulation performance, so insulation materials used in refrigerators It is widely used in heat insulation boards for residential heat insulation walls, etc. This vacuum heat insulating material includes a core material and a film for a vacuum heat insulating material covering the core material. [0003] As a film for vacuum heat insulating materials, excellent gas barrier properties are required in order to prevent intrusion of external air (air) and maintain a vacuum state for a long period of time. Therefore, a laminated film including a protective l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L59/06B32B15/08B32B15/088B32B27/28B32B27/34

CPCB32B15/08B32B15/20B32B27/08B32B27/306B32B27/32B32B27/34B32B27/36B32B2307/304B32B2307/31B32B2307/7242Y10T428/231Y10T428/2817F16L59/065

Inventor 福泽良一村井俊之

Owner OKURA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com