Vertical type wet spinning method and device

A wet spinning and vertical technology, which is applied in the field of vertical wet spinning, can solve the problems such as the dispersion of molecular structure orientation, and achieve the effect of improving the tensile breaking strength of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

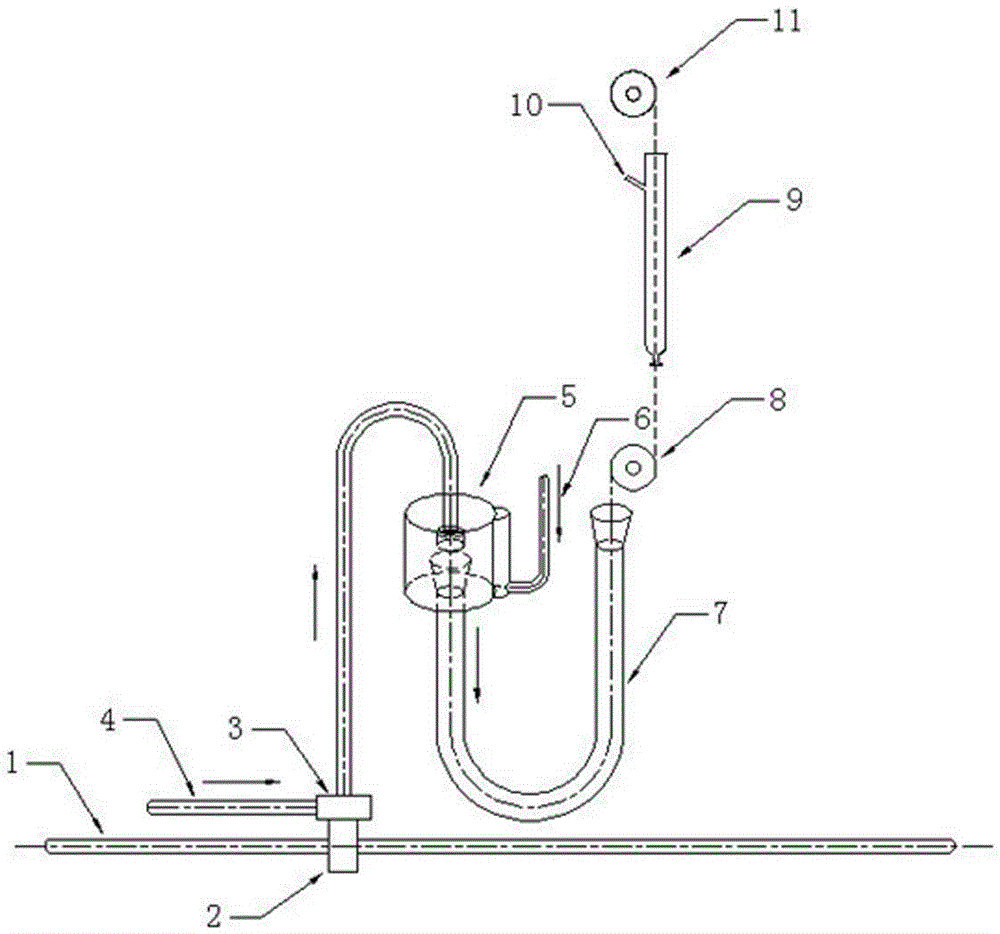

[0025] A vertical wet spinning device, including a pump shaft, a pump shaft clutch, a metering pump, a raw liquid main pipe, a coagulation bath, a primary coagulation liquid pipeline, a U-shaped coagulation bath tube, a first godet, and a straight coagulation bath The pump shaft clutch is set on the pump shaft, the raw liquid main pipe is connected to the coagulation bath through the metering pump set on the pump shaft clutch, the primary coagulation liquid pipeline is connected to the coagulation bath, and the coagulation bath Connect with one end of the U-shaped coagulation bath tube, set the first godet above the other end of the coagulation bath, set the straight coagulation bath tube on the upper end of the first godet, and set the second coagulation bath tube on the upper end of the straight coagulation bath tube. Godet.

[0026] An overflow port is provided on the straight coagulation bath pipe.

[0027] A spinneret is arranged in the coagulation bath, and the spinnere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com