Partition plate of lead storage battery and lead storage battery

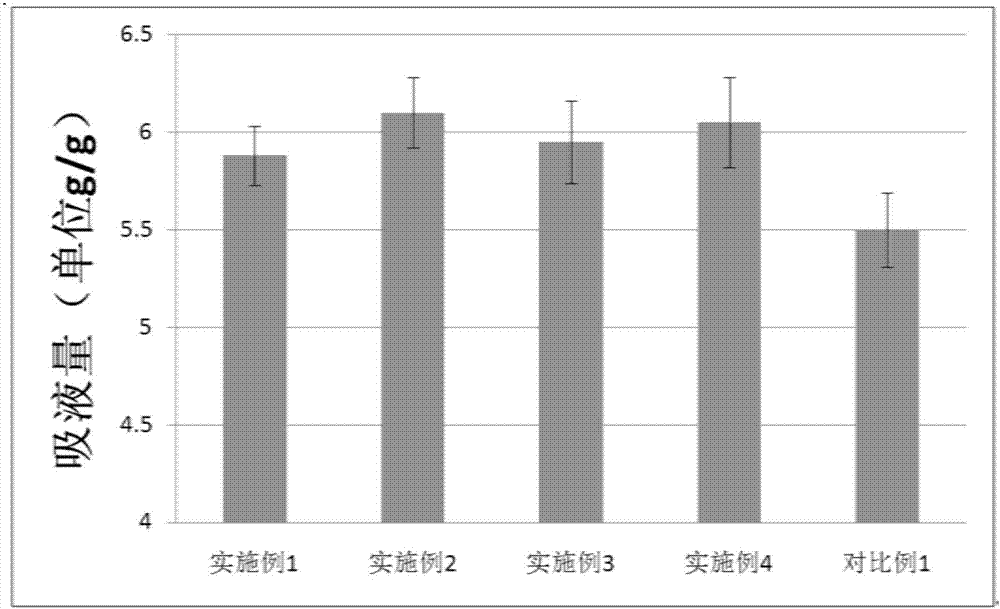

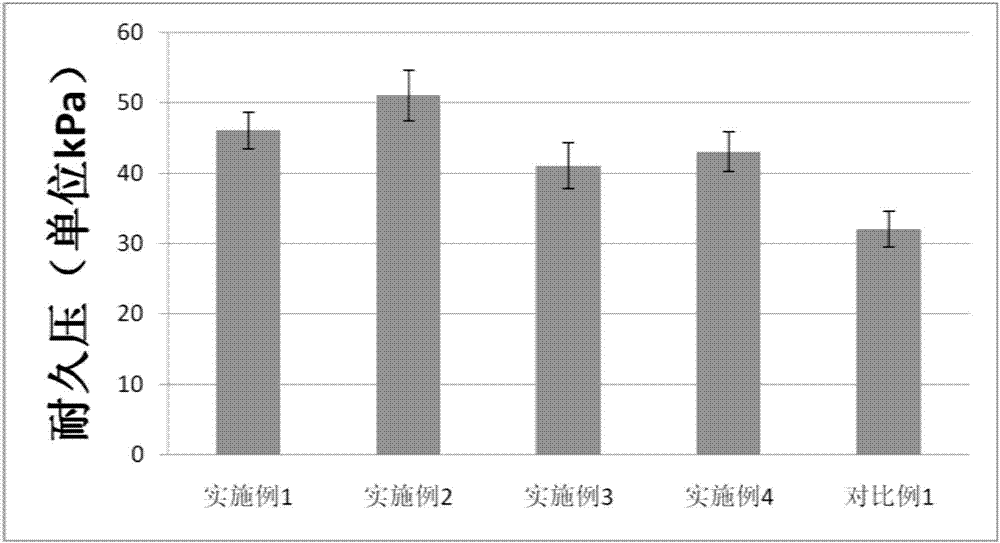

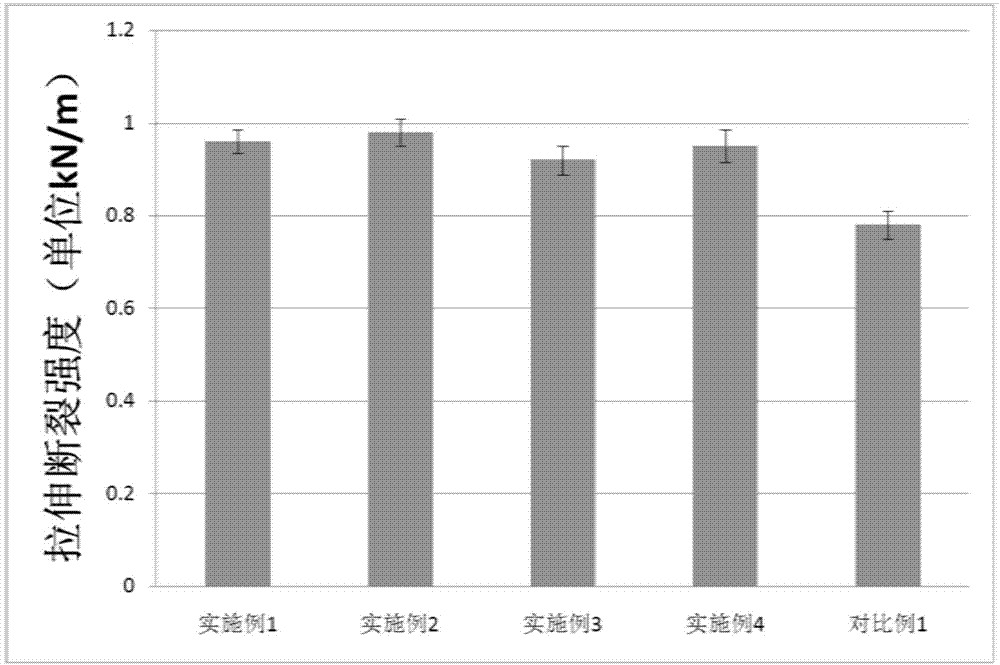

A technology for lead-acid batteries and separators, which can be used in lead-acid batteries, battery components, circuits, etc., and can solve problems such as uneven pore size distribution, small pore size, and high tensile fracture strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 15kg of PA / COPET sea-island fibers with a linear density of 0.62dtex and 40 islands / root for acid treatment to obtain superfine fibers. The acid treatment method is to put the sea-island fibers into 10% H 2 SO 4 In the solution, stir for 20 minutes to make the sea-island fibers fully contact with the acid solution, dissolve the "sea" (PA) of the PA / COPET sea-island fibers in the acid solution, and obtain 8.5kg of modified polyester superfine fiber bundles in the form of COPET. (COPET sea-island silk), the fineness of the dispersed modified polyester sea-island fiber is 0.01D.

[0028] Take by weighing 4.5kg of COPET island-in-the-sea silk with a fineness of 0.01D prepared above, 25.5kg of glass fibers (wherein 29° glass fiber accounts for 45%, and 35° glass fiber accounts for 55%), both total 30kg (COPET sea-island silk accounts for 15%) %), add 12 tons of water and mix it into a slurry, and use the wet forming process to manufacture sea-island / glass fiber nonwov...

Embodiment 2

[0030] Weigh 15kg of PA / COPET sea-island fibers with a linear density of 0.69dtex and 50 islands / root for acid treatment to obtain superfine fibers. The acid treatment method is to put the sea-island fibers into 15% H 2 SO 4 In the solution, stir for 20 minutes to make the sea-island fibers fully contact with the acid solution, dissolve the "sea" (PA) of the PA / COPET sea-island fibers in the acid solution, and obtain 8.2kg of COPET-shaped modified polyester superfine fiber bundles (COPET sea-island silk), the fineness of the dispersed modified polyester sea-island fiber is 0.008D.

[0031] Take by weighing 7.5kg of COPET island-in-the-sea yarns with a fineness of 0.008D, 22.5kg of glass fibers (wherein 29° glass fibers account for 45%, and 35° glass fibers account for 55%). %), add 12 tons of water and mix it into a slurry, and use the wet forming process to manufacture sea-island / glass fiber nonwoven materials. The drying process temperature is 40 minutes at 90°C, 40 minutes...

Embodiment 3

[0033] Weigh 15kg of PA / COPET sea-island fibers with a linear density of 0.60dtex and 60 islands / root for acid treatment to obtain superfine fibers. The acid treatment method is to put the sea-island fibers into 10% H 2 SO 4In the solution, stir for 20 minutes to make the sea-island fibers fully contact with the acid solution, dissolve the "sea" (PA) of the PA / COPET sea-island fibers in the acid solution, and obtain 8.7kg of COPET-shaped modified polyester superfine fiber bundles (COPET sea-island silk), the fineness of the dispersed modified polyester sea-island fiber is 0.006D.

[0034] Take by weighing the COPET island-in-the-sea silk 1.5kg with a fineness of 0.006D prepared above, glass fiber (wherein 29° glass fiber accounts for 45%, and 35° glass fiber accounts for 55%) 28.5kg, both total 30kg (COPET sea-island silk accounts for 5% %), add 12 tons of water and mix it into a slurry, and use the wet forming process to manufacture sea-island / glass fiber nonwoven materials....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com