Siloxane-containing vinyl chloride copolymer, preparation method of the siloxane-containing vinyl chloride copolymer, battery division plate prepared from the siloxane-containing vinyl chloride copolymer, and manufacturing method of the battery division plate

A technology of vinyl chloride copolymerization and battery separator, applied in chemical instruments and methods, battery pack components, circuits, etc., can solve problems such as affecting the performance and life of the battery, affecting the working efficiency of the battery, and the adhesive contaminating the electrolyte, etc. Achieve good strength, high mechanical strength and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A stainless steel autoclave with an internal volume of 100 mL was equipped with a temperature sensor, stirrer, reflux condenser, vinyl chloride monomer (VCM) feed line and initiator feed line. Metering pumps for VCM and initiator are connected to the reactor. Add a certain quality polyvinyl alcohol (polymerization degree 1700) and 1-vinyl heptaphenyl 8-arm silsesquioxane (POSS) monomer (analytical pure, Aldrich Company production), and then depressurized until reaching a vacuum of 50mmHg. Then add a certain quality of vinyl chloride monomer into the kettle. While stirring the material at a stirring speed of 800 rpm, the material was heated to 57°C. At the same time, 1% of the initiator azobisisobutyronitrile was added under pressure to start the polymerization reaction. After 48h, the polymerization reaction was completed, the unreacted monomers were collected, and the polymer slurry obtained by the reaction was poured into the ice methanol solution to allow the poly...

Embodiment 2

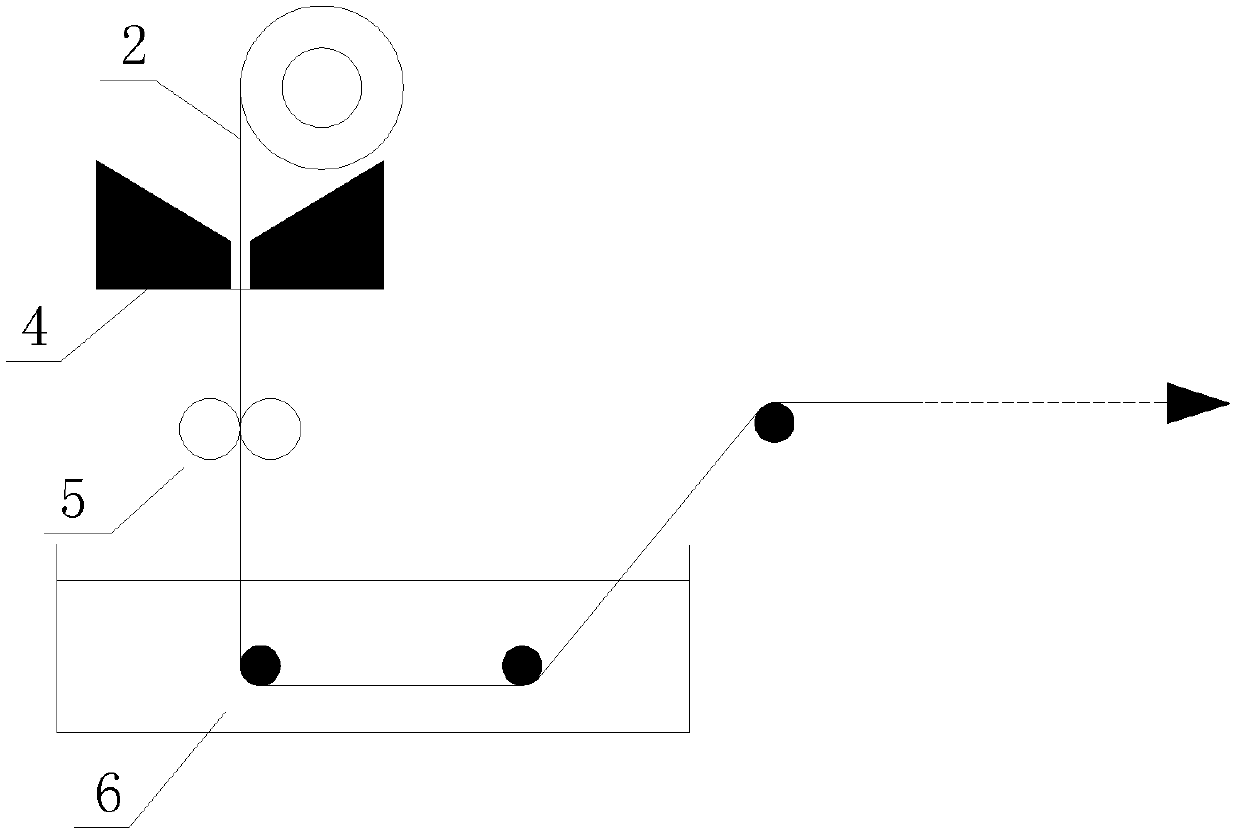

[0063] refer to figure 2 , the manufacture method of storage battery separator of the present invention, its steps are as follows:

[0064] (1) 5g of the siloxane-containing vinyl chloride copolymer prepared in Example 1, 5g of polyethylene glycol-600, 0.05g of lead stearate and 0.005g of carbon black were dissolved in 25g of N, N-dimethyl In acetamide, this polymer solution is loaded into the cavity of coating head 4;

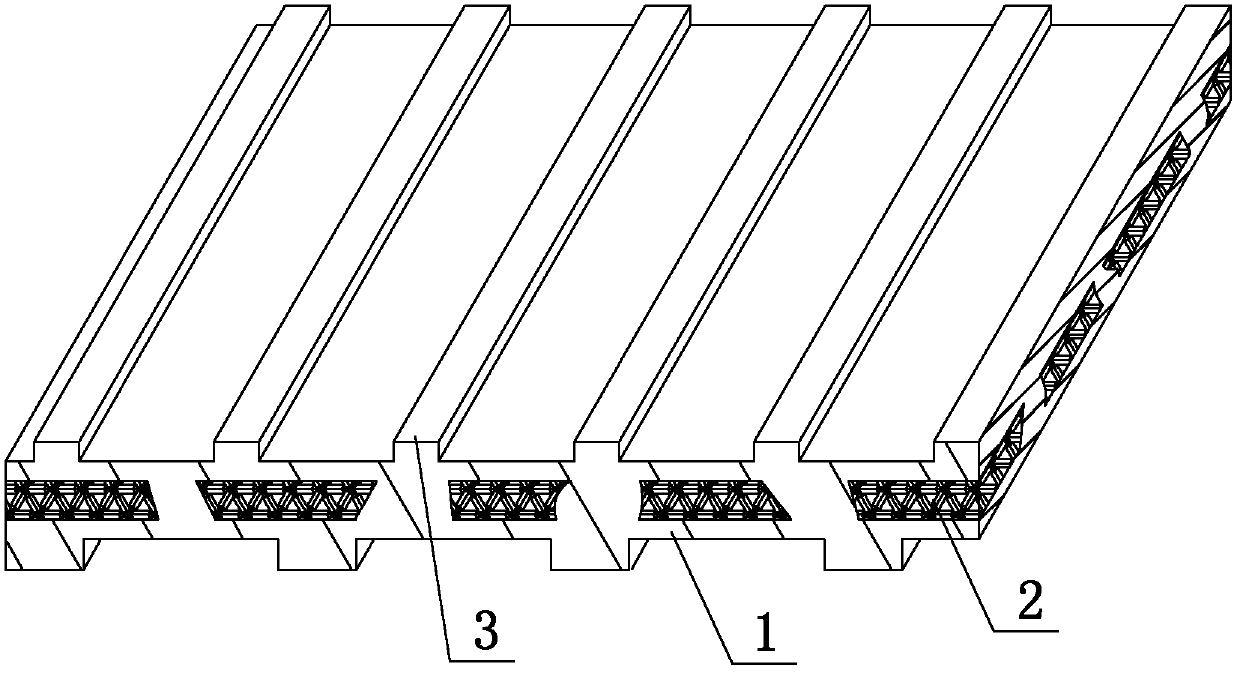

[0065] (2) Pass the 0.5mm thick non-woven fabric 2 with an average pore diameter of 10 μm through the 2mm size slit coating head 4, and move downward at a speed of 0.05m / s, while the polymer solution in the coating head 4 is evenly coated Apply to both sides of the non-woven fabric 2;

[0066] (3) The non-woven fabric coated with the polymer solution is pressed and formed, so that the polymer solution penetrates the pores of the non-woven fabric and is compounded with the non-woven fabric, and simultaneously forms ribs with 5mm spacing on both sides;

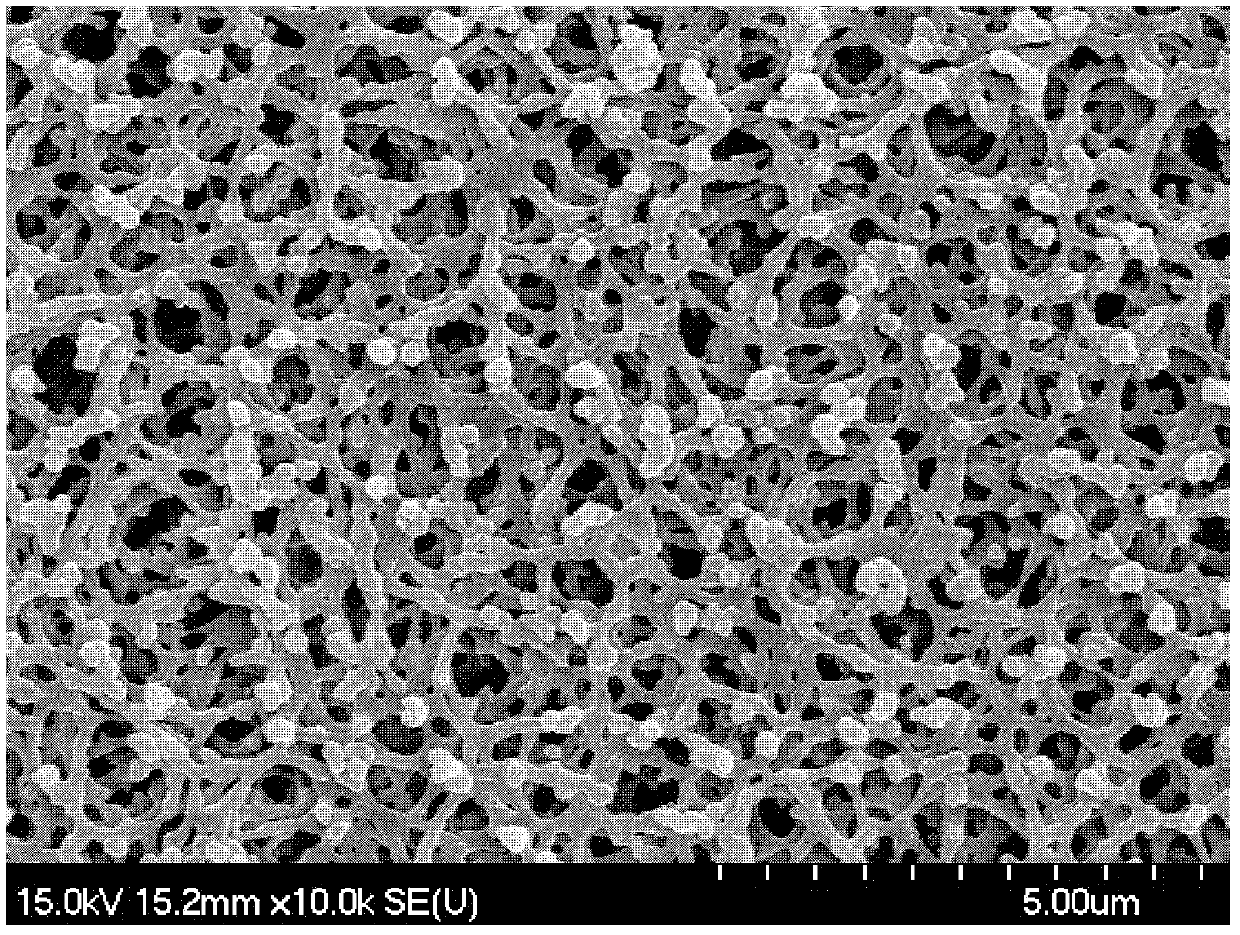

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com