A kind of lead storage battery separator and lead storage battery

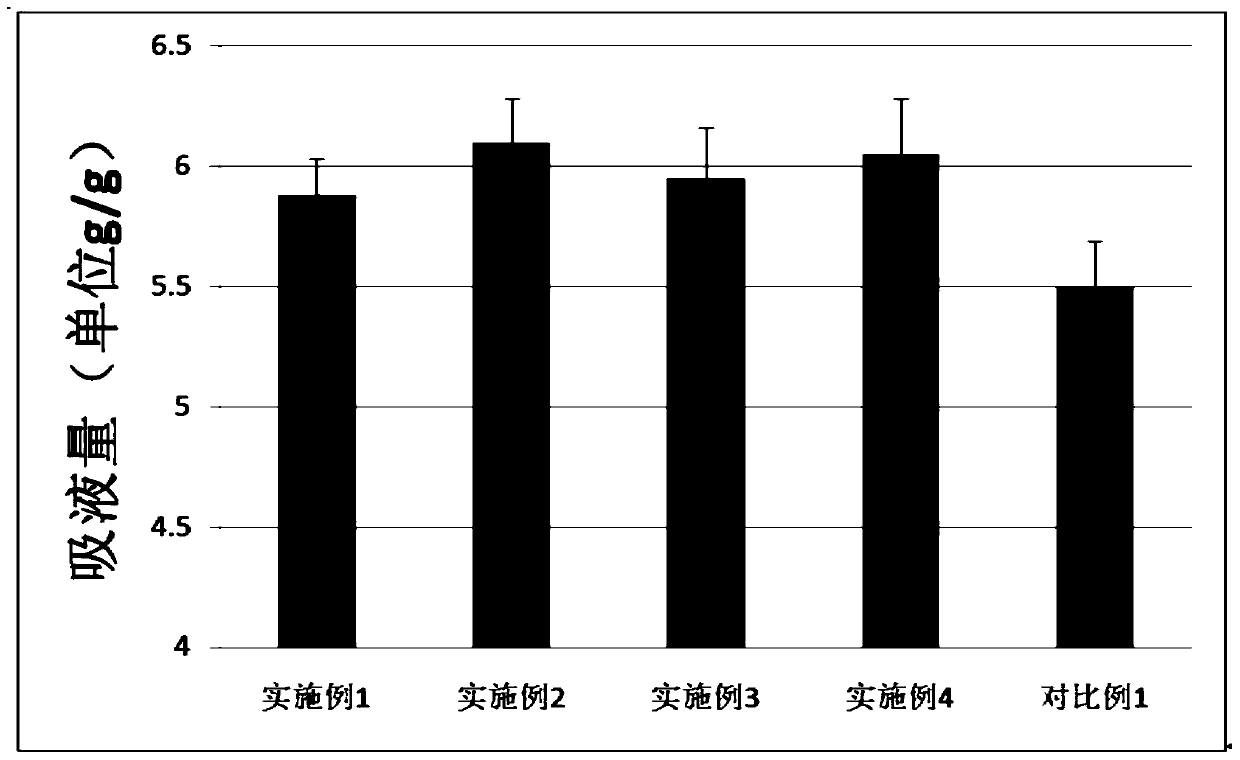

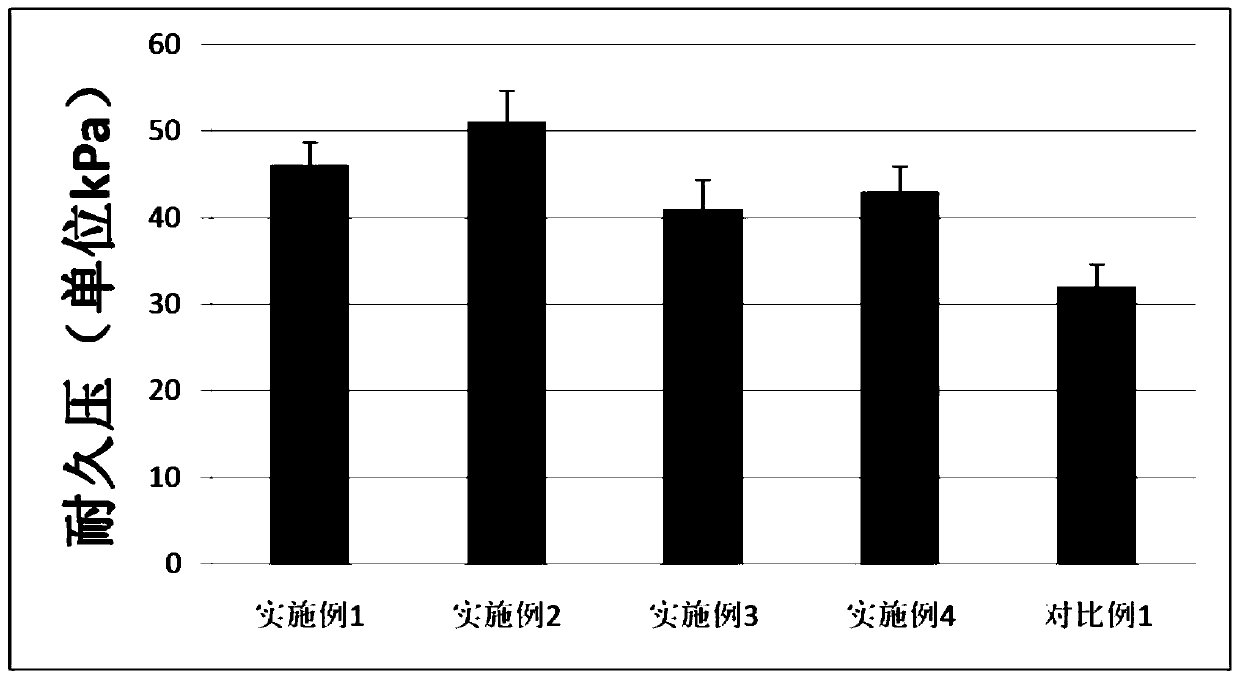

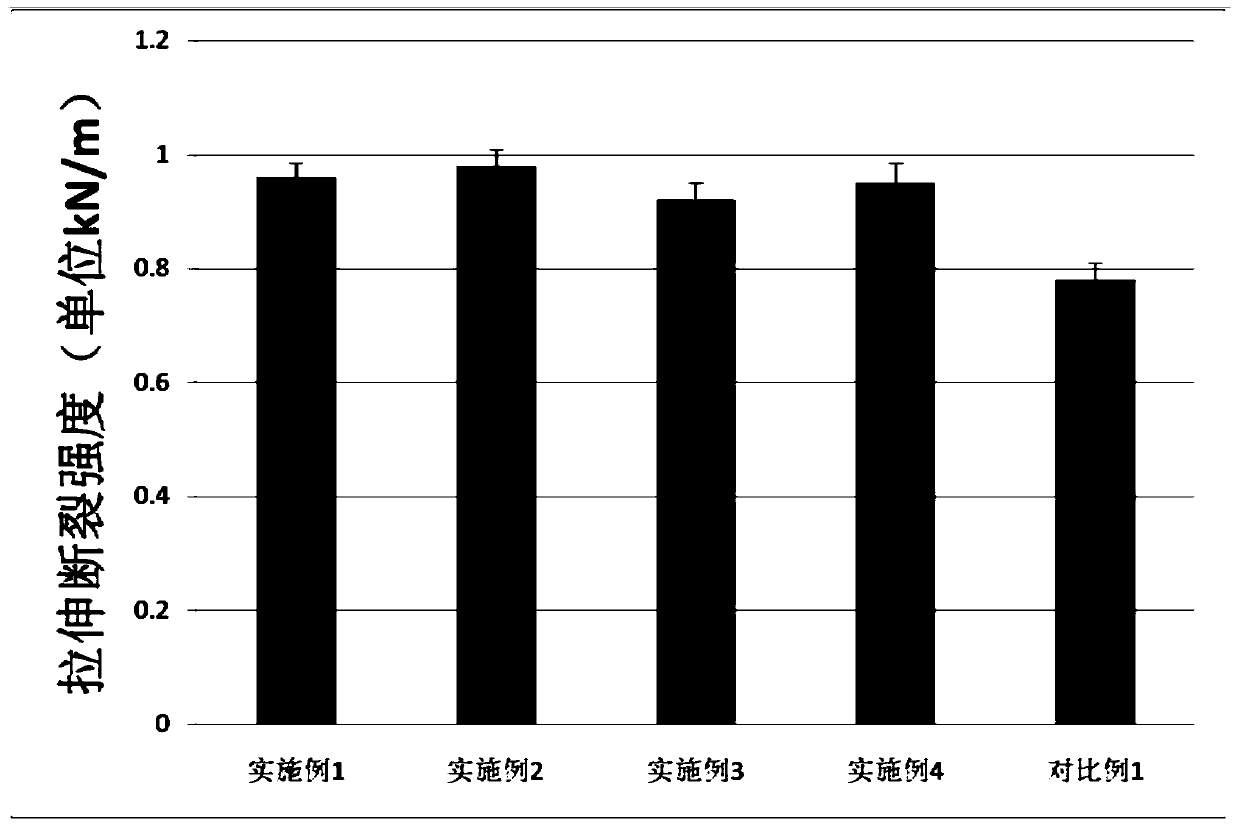

A technology for lead-acid batteries and separators, applied in lead-acid batteries, battery components, circuits, etc., can solve the problems of high tensile fracture strength, high durable pressure, and high acid absorption, and achieve high tensile fracture strength, Good application prospect, high acid absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 15kg of PA / COPET sea-island fibers with a linear density of 0.62dtex and 40 islands / root for acid treatment to obtain superfine fibers. The acid treatment method is to put the sea-island fibers into 10% H 2 SO 4 In the solution, stir for 20 minutes to make the sea-island fibers fully contact with the acid solution, dissolve the "sea" (PA) of the PA / COPET sea-island fibers in the acid solution, and obtain 8.5kg of modified polyester superfine fiber bundles in the form of COPET. (COPET sea-island silk), the fineness of the dispersed modified polyester sea-island fiber is 0.01D.

[0028] Take by weighing 4.5kg of COPET island-in-the-sea silk with a fineness of 0.01D prepared above, 25.5kg of glass fibers (wherein 29° glass fiber accounts for 45%, and 35° glass fiber accounts for 55%), both total 30kg (COPET sea-island silk accounts for 15%) %), add 12 tons of water and mix it into a slurry, and use the wet forming process to manufacture sea-island / glass fiber nonwov...

Embodiment 2

[0030] Weigh 15kg of PA / COPET sea-island fibers with a linear density of 0.69dtex and 50 islands / root for acid treatment to obtain superfine fibers. The acid treatment method is to put the sea-island fibers into 15% H 2 SO 4 In the solution, stir for 20 minutes to make the sea-island fibers fully contact with the acid solution, dissolve the "sea" (PA) of the PA / COPET sea-island fibers in the acid solution, and obtain 8.2kg of COPET-shaped modified polyester superfine fiber bundles (COPET sea-island silk), the fineness of the dispersed modified polyester sea-island fiber is 0.008D.

[0031] Take by weighing 7.5kg of COPET island-in-the-sea yarns with a fineness of 0.008D, 22.5kg of glass fibers (wherein 29° glass fibers account for 45%, and 35° glass fibers account for 55%). %), add 12 tons of water and mix it into a slurry, and use the wet forming process to manufacture sea-island / glass fiber nonwoven materials. The drying process temperature is 40 minutes at 90°C, 40 minutes...

Embodiment 3

[0033] Weigh 15kg of PA / COPET sea-island fibers with a linear density of 0.60dtex and 60 islands / root for acid treatment to obtain superfine fibers. The acid treatment method is to put the sea-island fibers into 10% H 2 SO 4In the solution, stir for 20 minutes to make the sea-island fibers fully contact with the acid solution, dissolve the "sea" (PA) of the PA / COPET sea-island fibers in the acid solution, and obtain 8.7kg of COPET-shaped modified polyester superfine fiber bundles (COPET sea-island silk), the fineness of the dispersed modified polyester sea-island fiber is 0.006D.

[0034] Take by weighing the COPET island-in-the-sea silk 1.5kg with a fineness of 0.006D prepared above, glass fiber (wherein 29° glass fiber accounts for 45%, and 35° glass fiber accounts for 55%) 28.5kg, both total 30kg (COPET sea-island silk accounts for 5% %), add 12 tons of water and mix it into a slurry, and use the wet forming process to manufacture sea-island / glass fiber nonwoven materials....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com