Conductive polymeric material and preparation method therefor

A technology of conductive polymers and conductive carbon black, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., to achieve good aging resistance, good electrical conductivity, and good low-temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

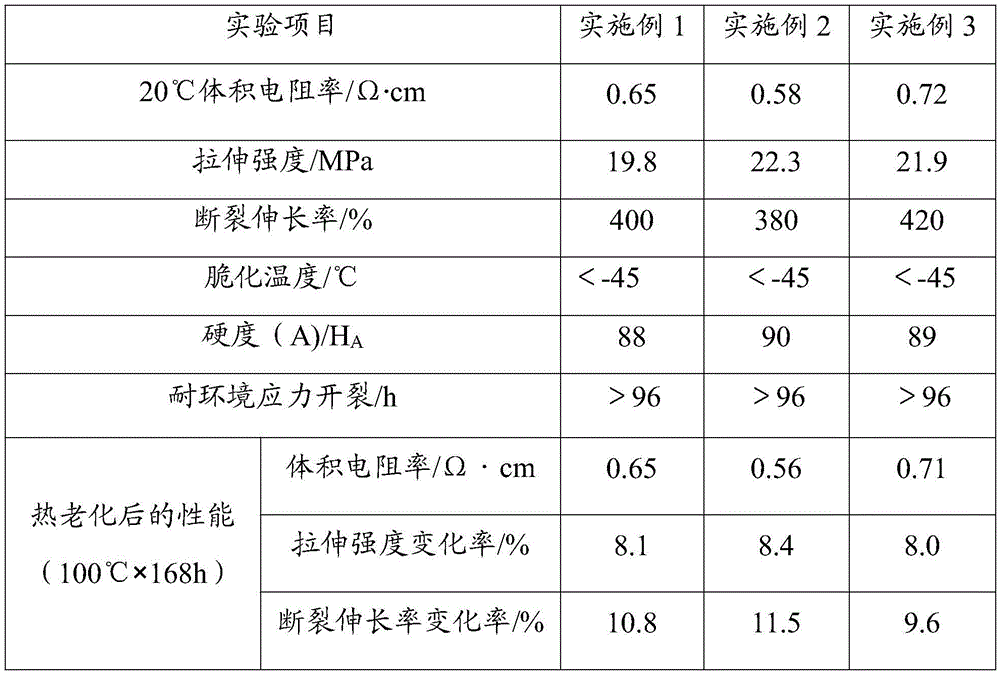

Examples

Embodiment 1

[0023] A conductive polymer material, its raw material is composed of the following components by weight: 25 parts of ethylene-vinyl acetate, 25 parts of ethylene-methyl acrylate, 2 parts of carbon nanotubes, 10 parts of conductive carbon black, 1 part of polyethylene Glycol, 2 parts of lignin, 0.1 part of stearic acid, 0.1 part of epoxy oil, 1 part of barium titanate, 0.1 part of antioxidant 1010, 0.1 part of polydimethylsiloxane.

[0024] The specific implementation steps are as follows:

[0025] Step 1, raw material preparation: Weigh 25 parts of ethylene-vinyl acetate, 25 parts of ethylene-methyl acrylate, 2 parts of carbon nanotubes, 10 parts of conductive carbon black, and 1 part of polyethylene glycol by weight. Alcohol, 2 parts of lignin, 0.1 part of stearic acid, 0.1 part of epoxy oil, 1 part of barium titanate, 0.1 part of antioxidant 1010, 0.1 part of polydimethylsiloxane, set aside;

[0026] Step 2, blending: put the raw materials weighed in step 1 into the mixer ...

Embodiment 2

[0030] A conductive polymer material, the raw material of which is composed of the following components by weight: 35 parts of ethylene-vinyl acetate, 20 parts of polyethylene, 10 parts of polypyrrole, 6 parts of carbon nanotubes, 12 parts of conductive carbon black, 1.5 parts Polyethylene glycol, 3.5 parts of lignin, 0.5 parts of stearic acid, 0.5 parts of epoxy oil, 1.5 parts of barium titanate, 0.15 parts of antioxidant 1010, 0.05 parts of antioxidant CA, 0.2 parts of polydimethylsiloxane alkyl.

[0031] The specific implementation steps are as follows:

[0032] Step 1, raw material preparation: Weigh 35 parts of ethylene-vinyl acetate, 20 parts of polyethylene, 10 parts of polypyrrole, 6 parts of carbon nanotubes, 12 parts of conductive carbon black, 1.5 parts of Polyethylene glycol, 3.5 parts of lignin, 0.5 parts of stearic acid, 0.5 parts of epoxy oil, 1.5 parts of barium titanate, 0.15 parts of antioxidant 1010, 0.05 parts of antioxidant CA, 0.2 parts Polydimethylsilo...

Embodiment 3

[0037] A conductive polymer material, its raw material is composed of the following components by weight: 35 parts of ethylene-vinyl acetate, 25 parts of polyethylene, 10 parts of polypropylene, 10 parts of polyaniline, 10 parts of carbon nanotubes, 15 parts of conductive Carbon black, 2 parts of polyethylene glycol, 5 parts of lignin, 1 part of stearic acid, 1 part of epoxy oil, 2 parts of barium titanate, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 1076, 0.1 part of antioxidant Oxygen agent CA, 0.5 parts of polydimethylsiloxane.

[0038] The specific implementation steps are as follows:

[0039] Step 1, raw material preparation: Weigh 35 parts of ethylene-vinyl acetate, 25 parts of polyethylene, 10 parts of polypropylene, 10 parts of polyaniline, 10 parts of carbon nanotubes, 15 parts of conductive Carbon black, 2 parts of polyethylene glycol, 5 parts of lignin, 1 part of stearic acid, 1 part of epoxy oil, 2 parts of barium titanate, 0.2 parts of antioxidant 1010,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com