Storable low-salt half-dry fish fillet and processing method and application thereof

A technology for semi-dried fish fillets and a processing method, which is applied in food processing, dry preservation of meat/fish, chemical preservation of meat/fish, etc. Salt consumption trends and other issues, to achieve the effect of improving product flavor, mellow taste, and cooking convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

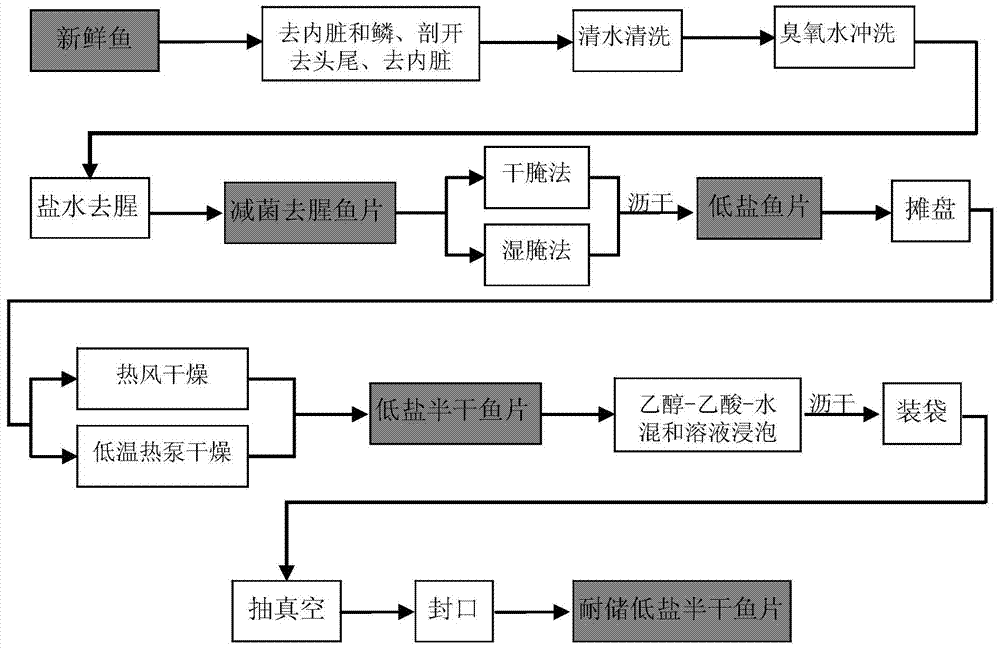

Method used

Image

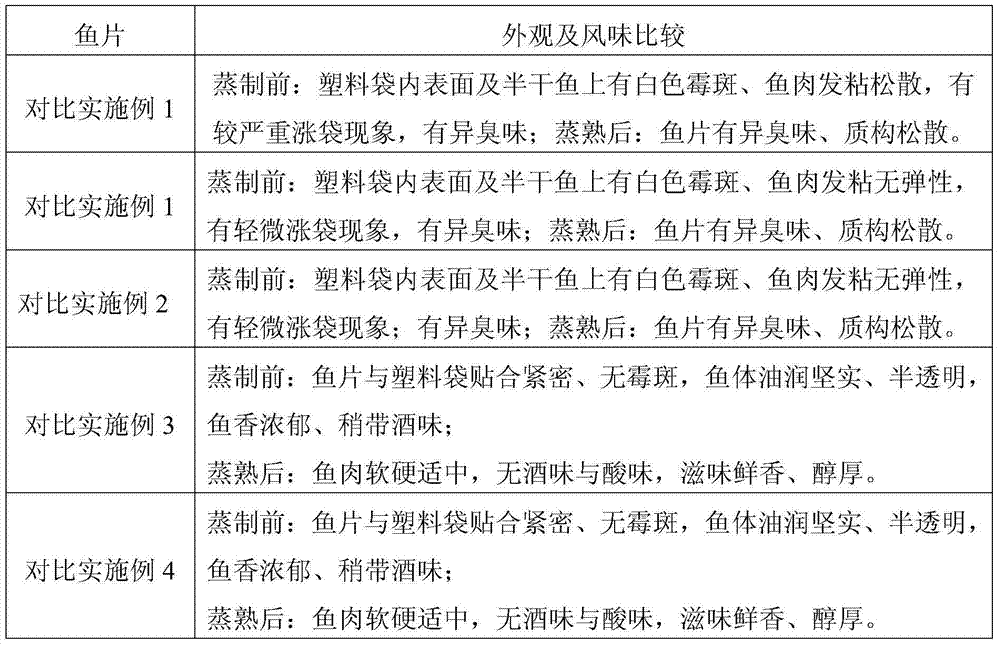

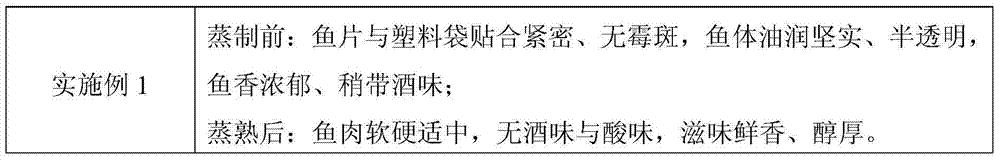

Examples

Embodiment 1

[0033] (1) Take fresh tilapia, remove viscera and scales, cut open along the back or abdomen (do not cut off), turn over, flatten to form nearly symmetrical fish fillets except for the tail part, wash with clean water, and then Rinse with 5ppm ozone water, use 2% (w / w) salt water to wash to remove fishy smell, and obtain reduced bacteria and fishy tilapia fillets;

[0034] (2) Adopt the dry salting method, that is, sprinkle salt on the inner and outer surfaces of the reduced bacteria and fishy tilapia fillets obtained in step (1), the amount of salt used is 6% (w / w) of the weight of the fish fillets; marinate at 4°C 8h, to obtain low-salt tilapia fillets;

[0035] (3) Use two 30W ultraviolet lamps to sterilize the interior of the low-temperature heat pump drying chamber (4m×3m×2.2m), stainless steel shelves and screens for 30 minutes; arrange the low-salt tilapia fillets obtained in step (2) Spread a single layer on a stainless steel screen (that is, a spreading pan), place i...

Embodiment 2

[0039] (1) Take fresh yellow croaker, remove viscera and scales, cut open along the back or abdomen (do not cut off), turn over, flatten to form nearly symmetrical fish fillets except for the tail part, wash with water, and reuse Rinse with 10ppm ozone water, wash with 4% (w / w) salt water to remove fishy smell, and obtain yellow croaker fillets with reduced bacteria and fishy smell;

[0040] (2) Adopt the dry salting method, that is, sprinkle salt on the inner and outer surfaces of the reduced bacteria and fishy yellow croaker fish fillets obtained in step (1), the amount of salt used is 4% (w / w) of the weight of the fish fillets, and marinate at 0°C for 6 hours , to obtain low-salt yellow croaker fillets;

[0041] (3) Use two 30W ultraviolet lamps to sterilize the interior of the low-temperature heat pump drying room (4m×3m×2.2m), stainless steel shelves and screens for 30 minutes; arrange the low-salt yellow croaker fillets obtained in step (2) and single Spread the layers ...

Embodiment 3

[0045] (1) Take fresh herring, remove viscera and scales, cut open along the back or abdomen (do not cut off), turn over, flatten to form nearly symmetrical fish fillets except for the tail part, wash with water, and then use 3ppm Wash with ozone water, use 1% (w / w) salt water to wash and remove fishy smell, and obtain reduced bacteria and fishy herring fillets;

[0046] (2) Using dry salting method, sprinkle salt, sugar and pepper powder on the inner and outer surfaces of herring pieces, the amount of salt is 8% of the weight of the fish fillet (w / w), the amount of sugar is 3% of the weight of the fish fillet, and the amount of pepper powder is 0.2% of the weight of the fish fillets, marinated at 2°C for 2 hours to obtain seasoned low-salt herring fillets;

[0047] (3) Use two 30W ultraviolet lamps to sterilize the interior of the low-temperature heat pump drying room (4m×3m×2.2m), stainless steel shelves and screens for 30 minutes; arrange the seasoned low-salt herring fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com