Processing method for vacuum frozen puffed beef cube

A technology of vacuum freezing and processing methods, which is applied in the fields of application, food preparation, food science, etc. It can solve the problems of affecting product sensory evaluation, short shelf life of diced beef, and high product hardness, so as to achieve complete shape, good crispness, and increase additional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

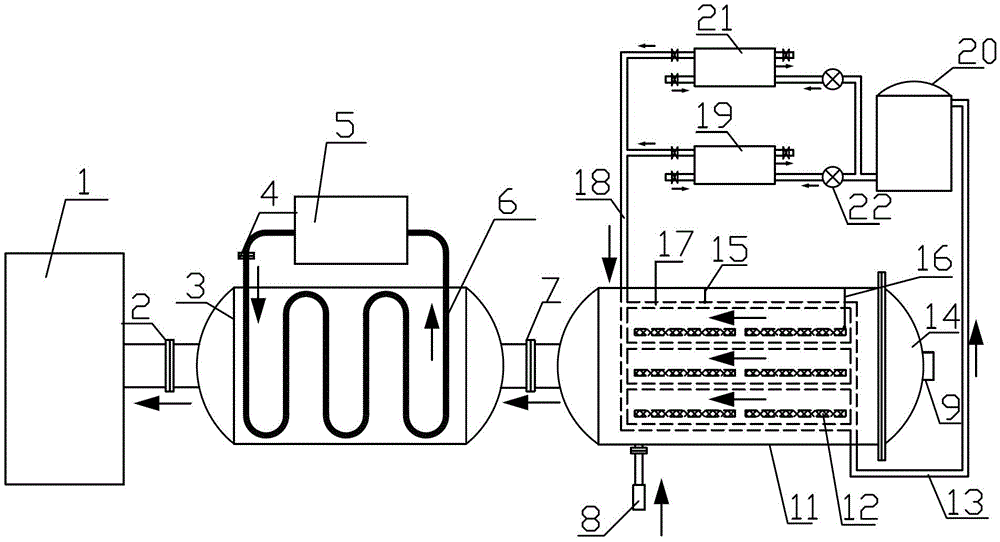

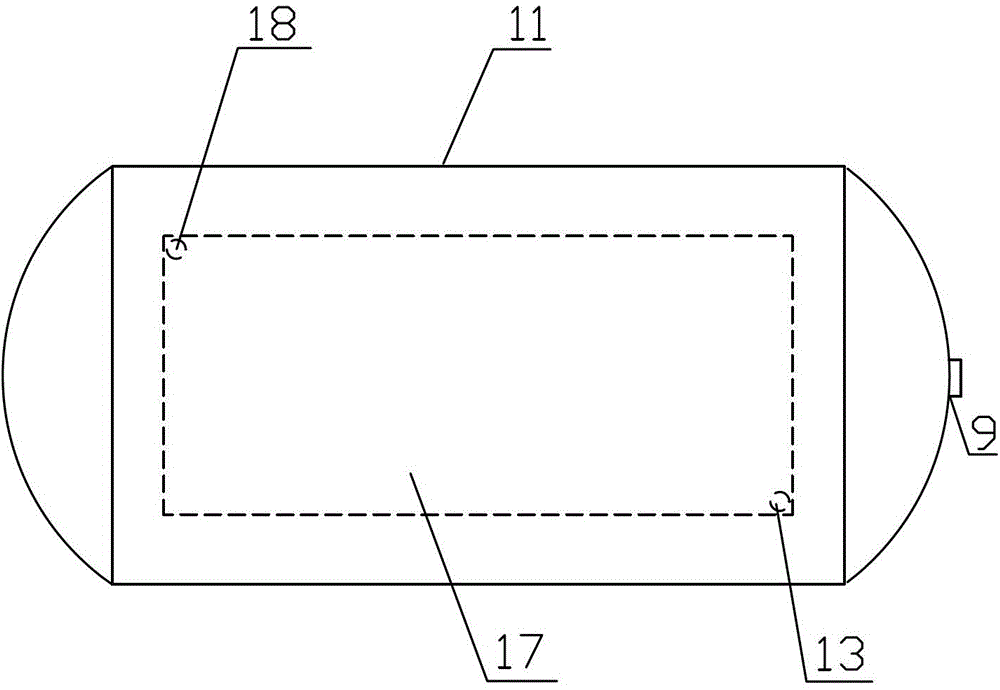

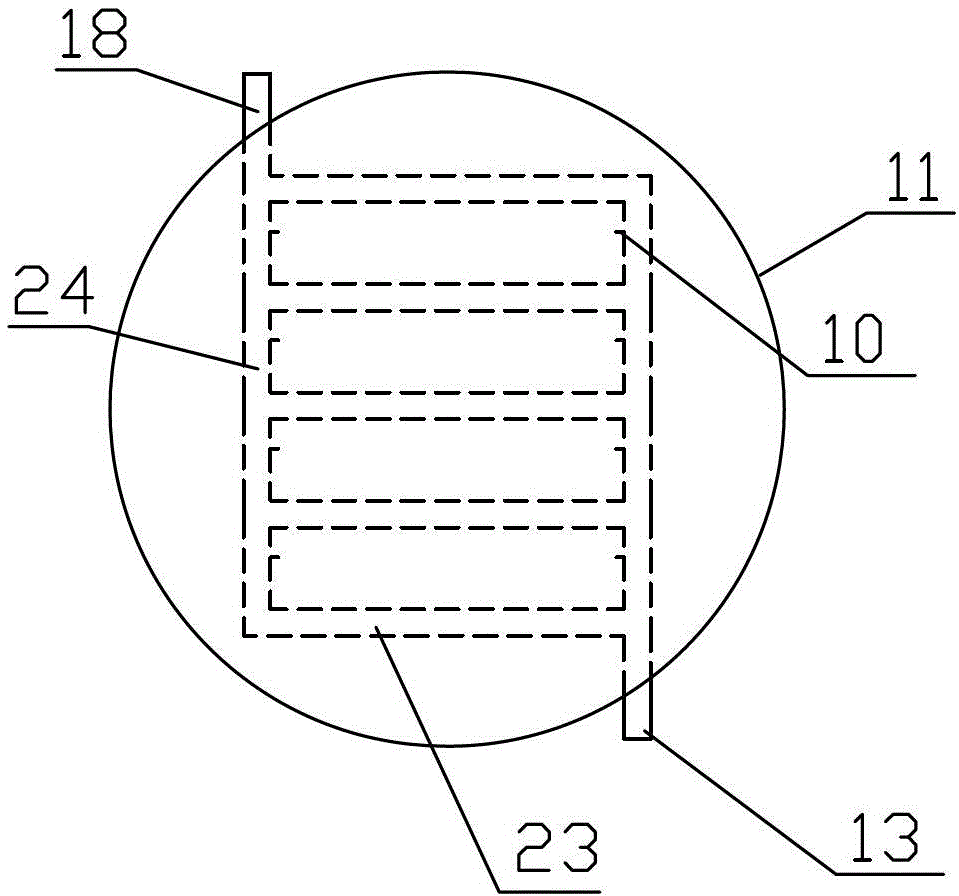

[0023] Refer to the attached figure 1 to attach Figure 4 A kind of processing method of vacuum freezing puffed diced beef of the present invention is described in detail below.

[0024] A processing method of vacuum frozen puffed diced beef of the present invention comprises the following steps: (1) raw material pretreatment: wash the fresh beef, cut into 500-1000g meat pieces, put the meat pieces into a pot and boil for 30 -40min, take it out, use a dicing machine to cut into diced beef of 1cm square, you can add different recipes of soup according to different tastes, boil and soak, wait for the soup to dry, take out the diced beef, and drain;

[0025](2) Spread the processed raw materials into a single layer, evenly distribute them on the material tray 12, put them into the quick-freezing machine, and perform quick-freezing at -40°C for 4-6 hours to ensure that the moisture in the diced beef is completely frozen;

[0026] (3) Vacuum freeze-expansion drying by vacuum free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com