Method for preparing dry-cured goose through Lysostaphin co-fermentation of goose meat

A technology of bacteria-enzyme combination and composite starter, which is applied in the field of bacteria-enzyme combined fermentation of goose meat to prepare goose, can solve the problems of sour fermentation, insufficient fragrance and umami taste, and long air-drying time, so as to reduce the fermentation temperature and Production time, increase aroma and color, reduce the effect of fermentation sourness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Fermentation condition multi-factor combination screening experiment

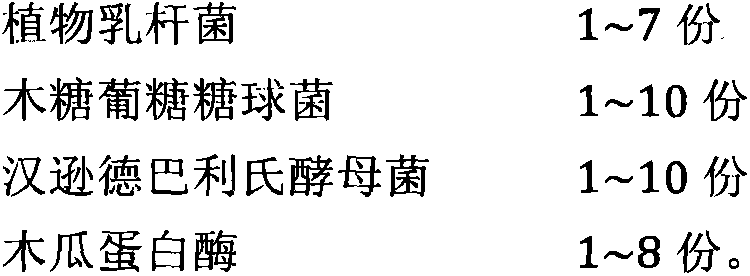

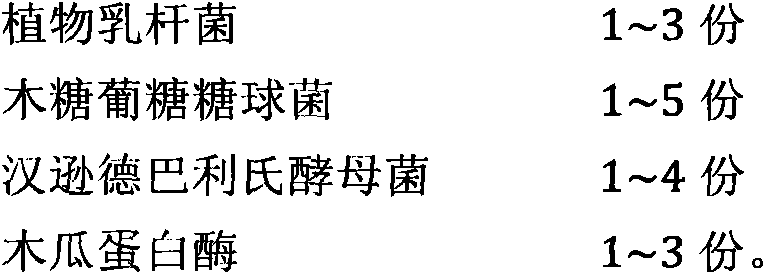

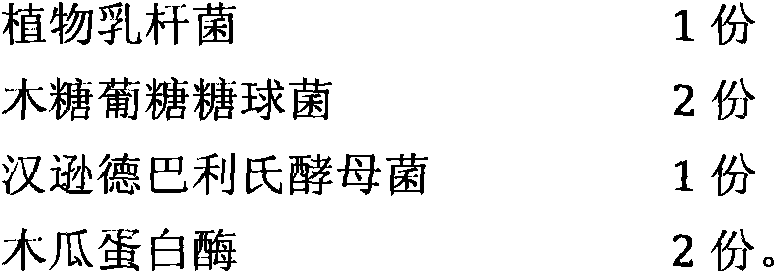

[0024] According to the results of the single factor test, four factors including the weight ratio of each bacterial enzyme in the compound fermentation agent, inoculation amount, air-drying fermentation temperature, and air-drying fermentation time were selected, as well as pH value and amino acid nitrogen content. Orthogonal experiments were carried out to further optimize the parameter values of each factor. The factor levels of the orthogonal test are shown in Table 1, and the results of the orthogonal test are shown in Table 2. Wherein, the enzyme ratio of bacteria A is the ratio by weight and number of enzymes of each bacteria in the compound starter, that is, the ratio by weight and number of Lactobacillus plantarum: Gluconococcus xylosus: Debaria hansenii: papain.

[0025] Table 1 Factor levels of fermentation wind goose factor orthogonal test

[0026]

[0027] Table 2 Ort...

Embodiment 2

[0031] A method for preparing wind goose by combined fermentation of goose meat with bacteria and enzymes, comprising the following steps:

[0032] Step 1: Preliminary pickling of raw goose meat: take the goose carcass, wash it with clean water, trim off the surface and internal fat, lymph, blood vessels, congestion and dirt, rinse it with clean water until no blood is precipitated, and drain it , put 1 part by weight of table salt, 1 part of Chinese prickly ash, 0.05 part of star anise, and 0.1 part of sucrose into a frying pan, stir fry at 160°C for 5 minutes to prepare fried salt, and knead the fried salt evenly to the weight of The number is 80 parts of each part of the drained goose, put into 0 ℃ environment, marinate for 12h;

[0033] Step 2: inoculate, ferment and air-dry: take 0.5 parts by weight of the compound starter and inoculate and inject it into the marinated goose meat prepared in step 1, and place it in an environment with a temperature of 5°C and a relative h...

Embodiment 3

[0038] A method for preparing wind goose by combined fermentation of goose meat with bacteria and enzymes, comprising the following steps:

[0039] Step 1: Preliminary pickling of raw goose meat: take the goose carcass, wash it with clean water, trim off the surface and internal fat, lymph, blood vessels, congestion and dirt, rinse it with clean water until no blood is precipitated, and drain it , take 2 parts by weight of table salt, 2 parts of Chinese prickly ash, 0.1 part of star anise, and 0.2 part of sucrose in a wok, stir fry at 140°C for 8 minutes to prepare fried salt, and knead the fried salt evenly to the weight of The number is 90 parts of each part of the drained goose, put into 4 ℃ environment, marinate 9h;

[0040] Step 2: inoculate, ferment and air-dry: take 1 part by weight of the compound starter and inoculate and inject it into the marinated goose meat prepared in step 1, and place it in an environment with a temperature of 10°C and a relative humidity of 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com