Reusable inversion sleeve assembly for inversion of cured in place liners

A technology of flipping sleeves and sleeves, which is applied in the direction of pipe elements, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of not being suitable for large and medium diameter linings, and not providing steam for flat hoses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

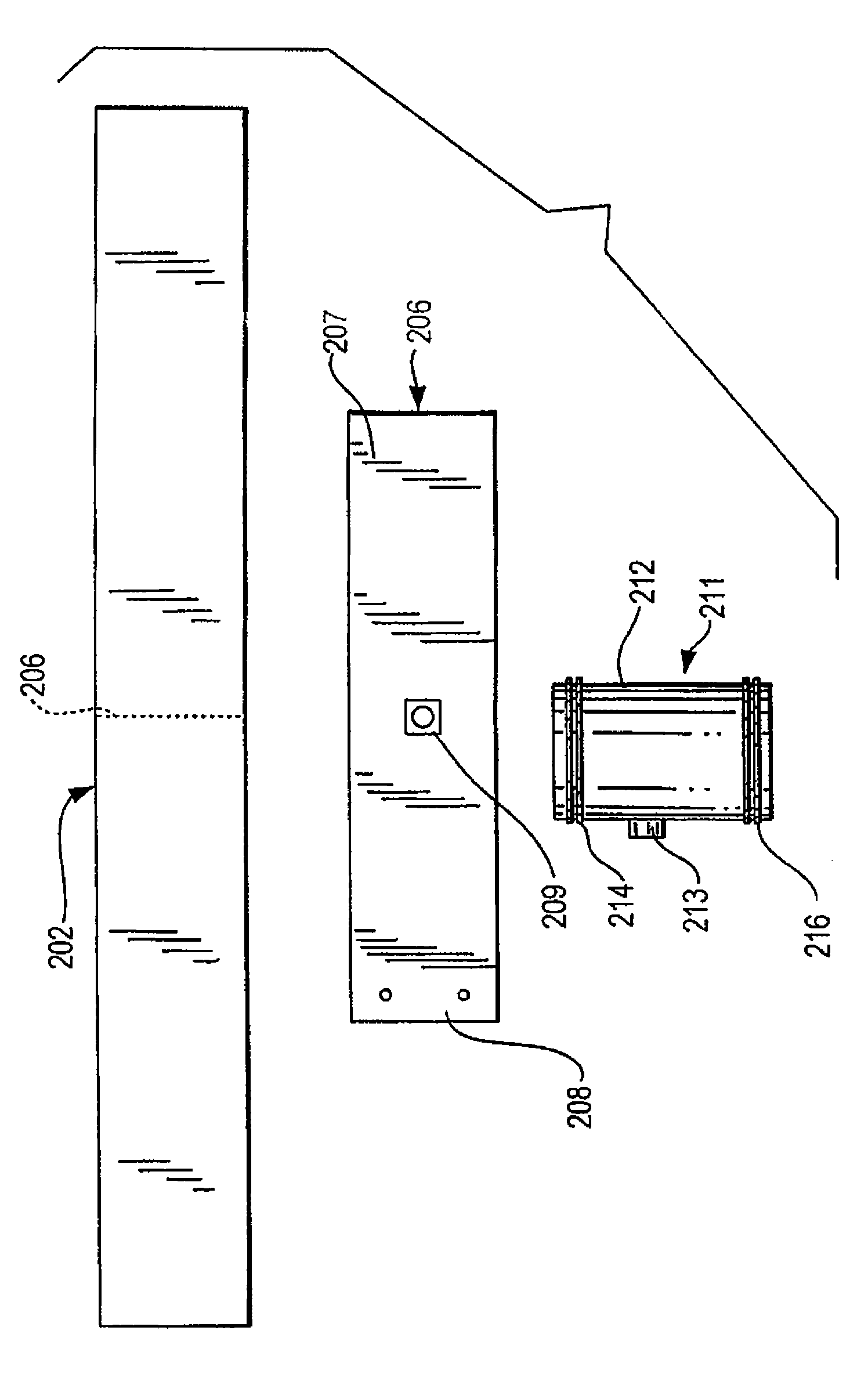

[0040] A "Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube" (Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube) to CIPP is described here. Improved method and apparatus for air inversion and steam curing of linings. The methods and apparatus described herein are fully applicable to the installation of medium diameter CIPP liners working from the surface through a structure, such as a manhole, to repair existing buried pipelines and pipelines.

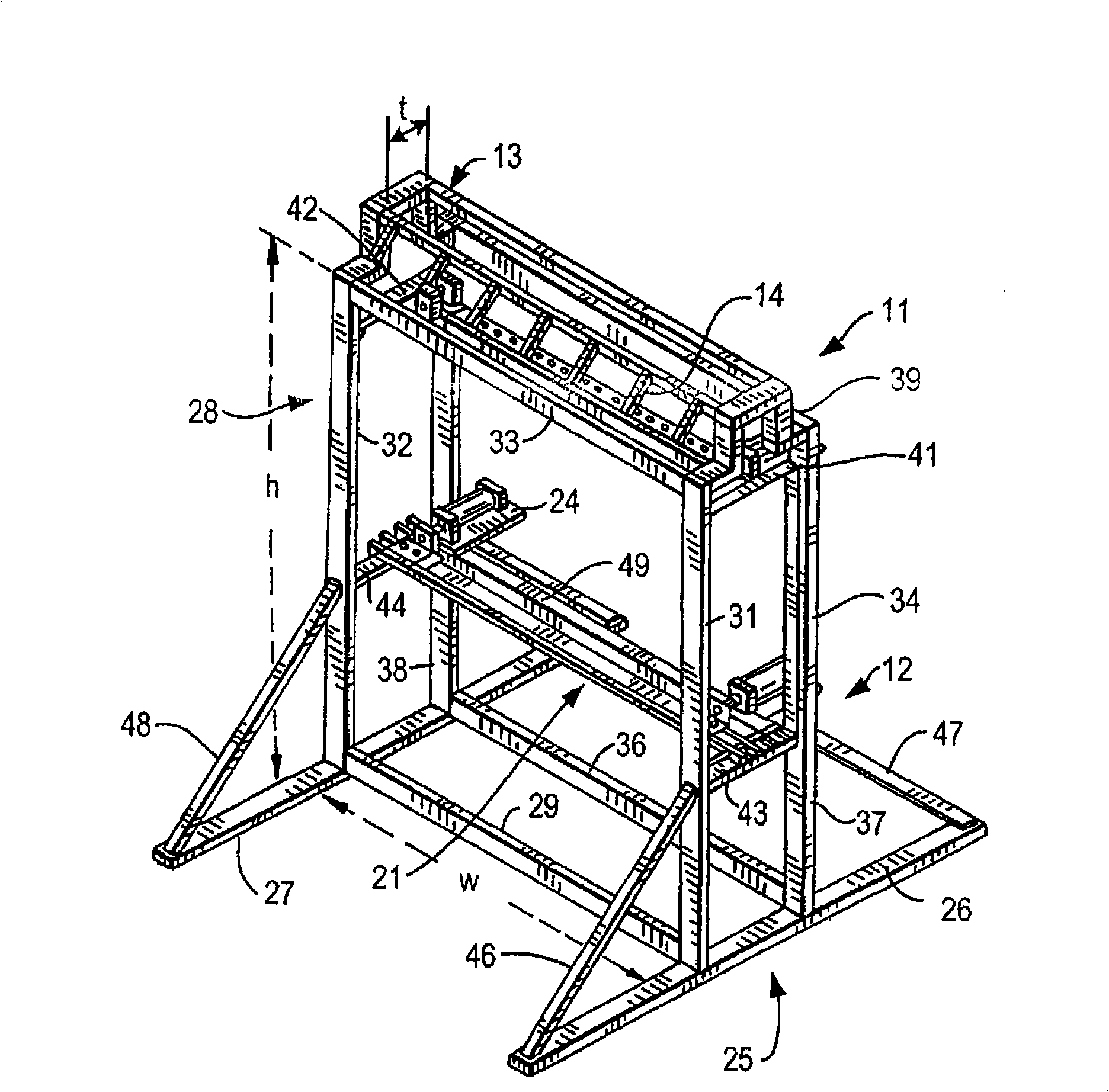

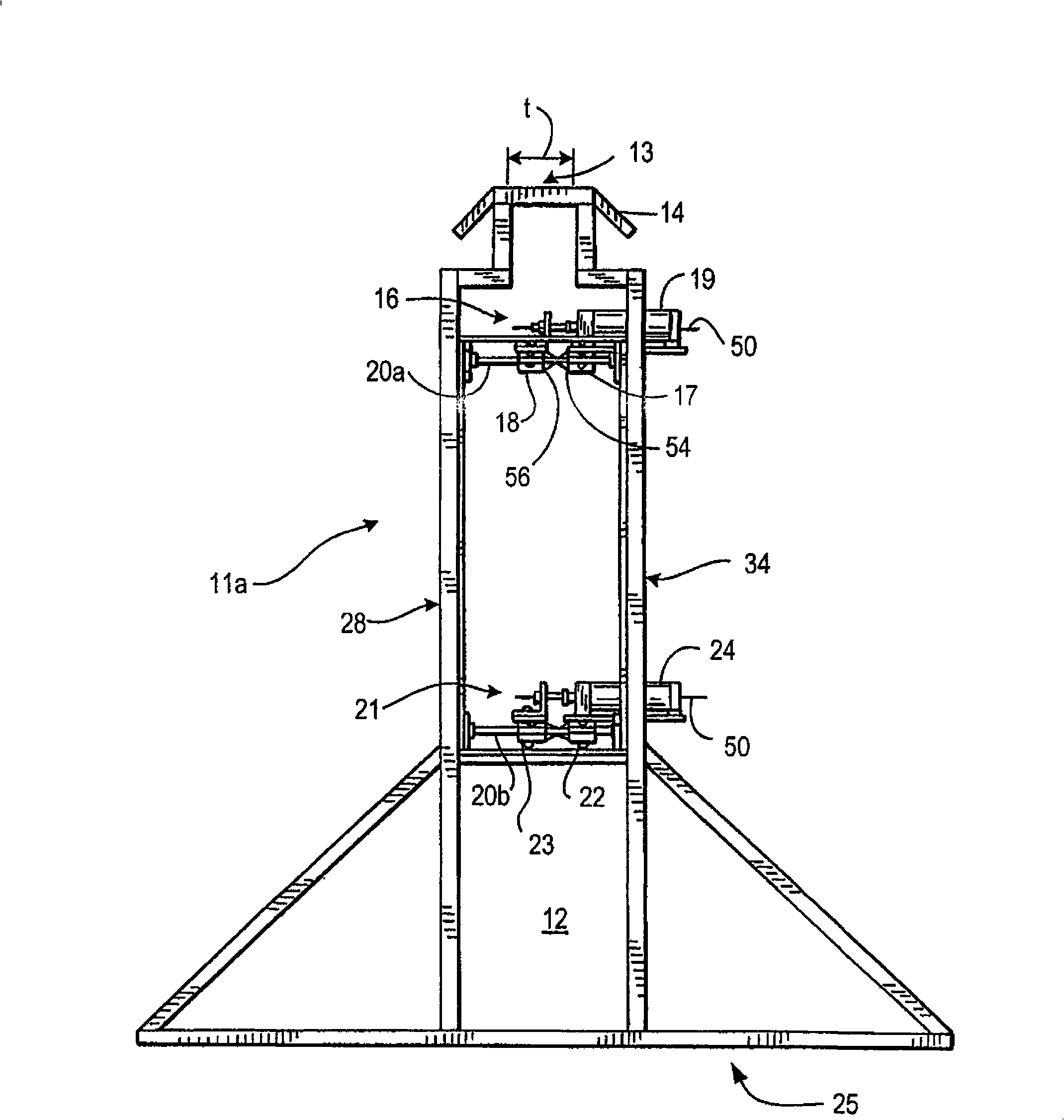

[0041] figure 1 There is shown an inverting device 11 having a single rigid lower gland 21 constructed and arranged in accordance with the present invention. Figure 1A A similar device 11a with an upper gland 16 and a lower gland 21 is shown. Considering the similarity of components, in figure 1 and Figure 1A The same reference numerals are used to denote the same components. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com