Lipidolysis oxidation controlling method in dry-cured duck processing process

A technology of processing and lipids, which is applied in the regulation of lipid oxidation in the processing of duck, and in the field of regulation of lipid decomposition and oxidation in the processing of duck, can solve the problem that the flavor quality of the product can not be reduced, and the oxidation index of the product can not be provided with sufficient time. , to achieve the effect of accelerating lipid decomposition and oxidation, shortening the production cycle, and reducing lipid oxidation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

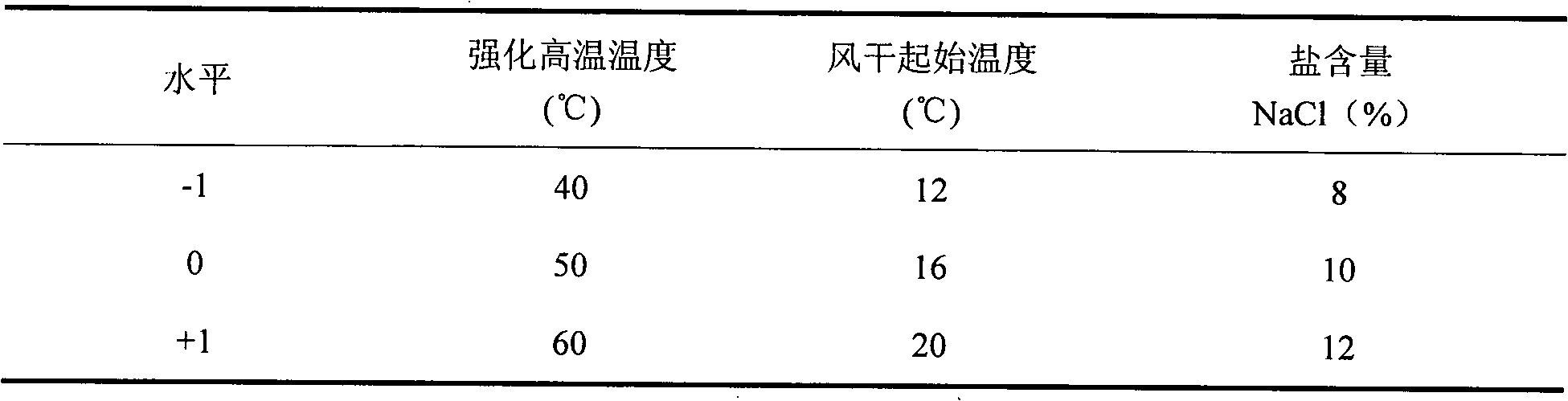

[0010] The regulation method of lipid oxidation in the process of wind duck processing is to wet-cure the fresh duck with 8%-12% salt for 24 hours, then air-dry it at a high temperature in the range of 40°C-60°C for 1 hour, and then start to air-dry and mature , the initial temperature of air-drying and maturation is controlled in the range of 12°C-20°C, and the air-drying and maturation is carried out for 72 hours in an environment with a relative humidity of 58±5%RH according to a program with a heating rate of 0.2-0.3°C / hour.

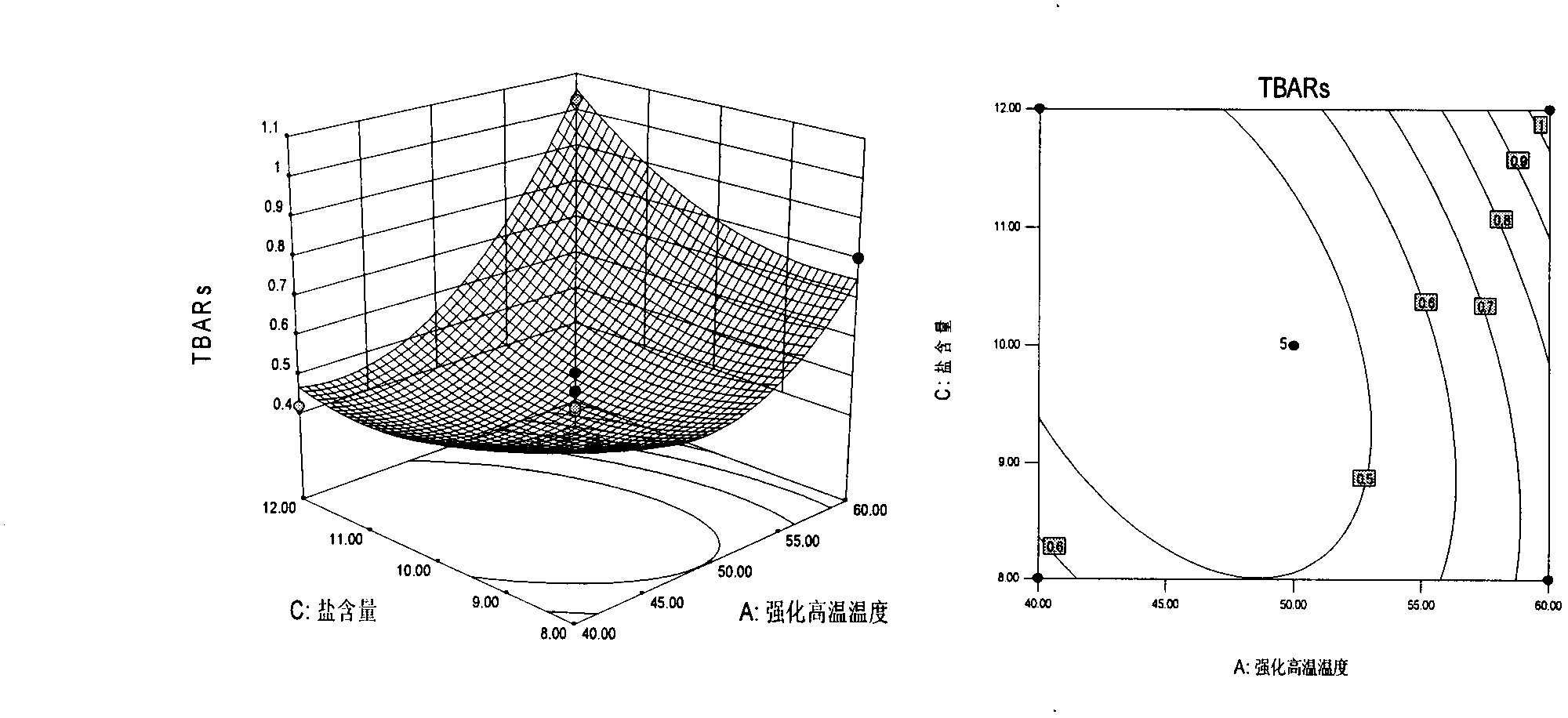

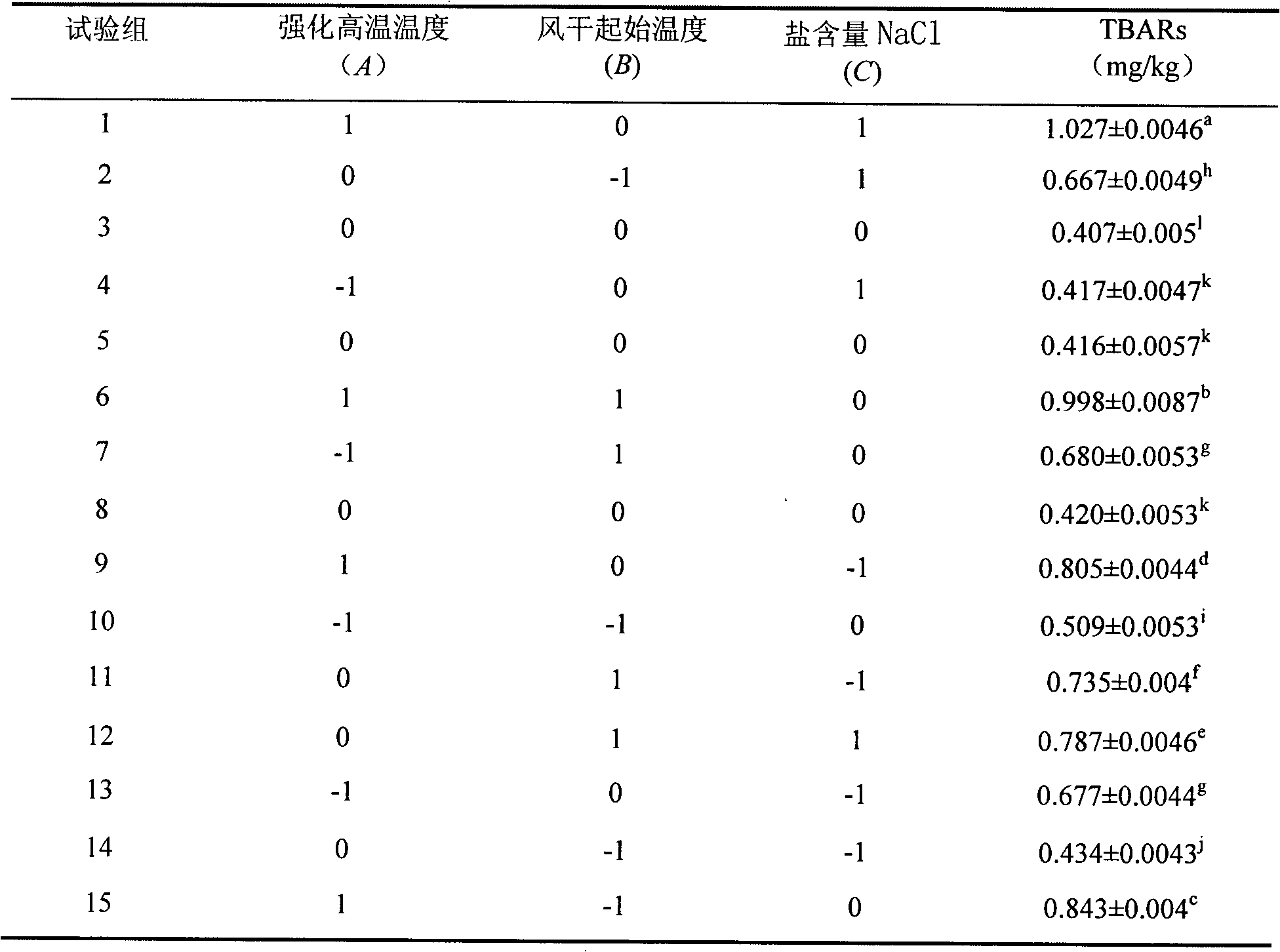

[0011] Taking the enhanced high temperature temperature, the starting temperature of air-drying, and the salt content as the experimental factors, the response surface test was designed according to Table 1; the lipid oxidation index TBARs of the duck product was used as the investigation index, and the test results are shown in Table 2: only when the enhanced high temperature temperature is 60 ℃, air-drying start temperature 16 ℃, and salt content 20...

Embodiment 2

[0022] Taking the lowest TBARs of the test product as an index, regression optimization was carried out on the enhanced high-temperature air-drying ripening process of Fengya, and the optimal process conditions were the enhanced high-temperature temperature of 45.41°C, the initial temperature of air-drying of 14.44°C, and the salt content of 10.07%. The research group's patent ZL200810023306.3 "air-dried high-temperature ripening process for air-dried ducks" (control group) and the optimal process of enhanced high-temperature ripening are based on five processes: raw materials, after pickling, air-dried for 1 day, air-dried for 2 days, and air-dried for 3 days Point sampling (three repeated samples were taken at each process point), and the determination of various indicators such as moisture content, salt content, LOX, TBARs, and peroxide value were carried out, as shown in Table 5. The results showed that: after enhanced high-temperature air-drying for 1 hour, the LOX activit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com