Method for producing A1Npowder with microwave carbon thermoreduction cooling-down catalysis calcination

A low-temperature catalysis and microwave technology, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve the problems of high cost, long time, high synthesis temperature, etc., and achieve the effect of simple operation, simple equipment and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

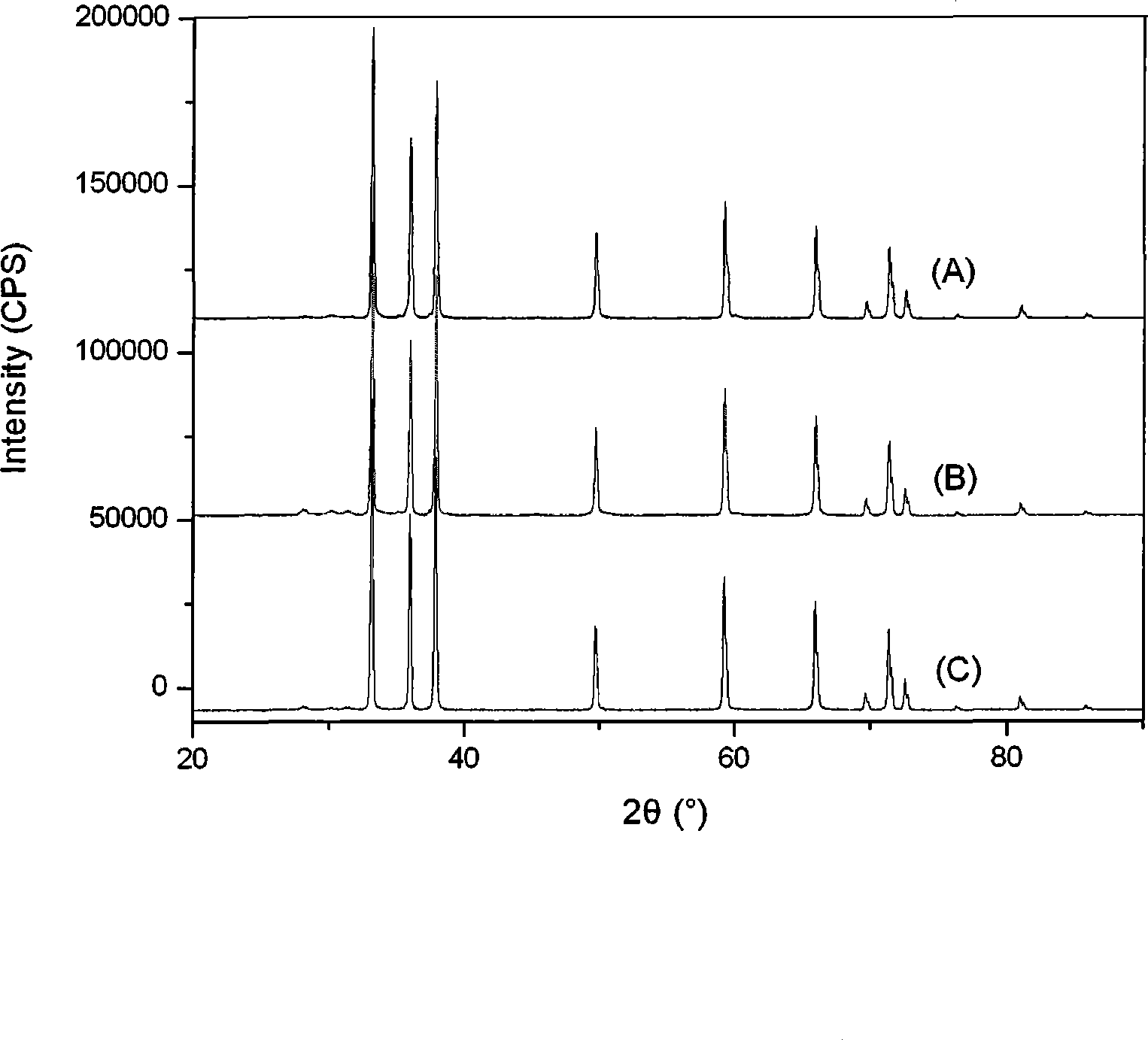

Embodiment 1

[0036] First, mix 100g of industrial aluminum hydroxide with 3g of ammonium chloride, add 50ml of deionized water, and perform wet ball milling for 30min at a ball milling speed of 300r / min. After ball milling, wash with boiling while stirring, the boiling time is 30min, filter with suction, then wash with boiling for three times as above, filter with suction, dry to obtain the mixture of treated ammonium chloride and aluminum hydroxide. Then take 100g of the treated mixture of ammonium chloride and aluminum hydroxide and mix it with 77g of acetylene black, add 3.5g of aluminum powder, and ball mill with absolute ethanol for 5 hours at a speed of 300r / min. Dry after ball milling to obtain a precursor powder with fine particle size and uniform mixture of carbon and aluminum. Then put the precursor into a microwave high-temperature sintering furnace, set the temperature regime, and raise the temperature to 1200°C at a rate of 15°C / min in an ordinary nitrogen atmosphere, and keep...

Embodiment 2

[0038]First, mix 100g of industrial aluminum hydroxide with 9g of ammonium chloride, add 50ml of deionized water, and perform wet ball milling for 30min at a ball milling speed of 300r / min. After ball milling, wash with boiling while stirring, the boiling time is 30min, the stirring speed is 300r / min, and suction filtration. Boil and wash three times as above, filter with suction, and dry to obtain a mixture of treated ammonium chloride and aluminum hydroxide. Then take 100g of the treated mixture of ammonium chloride and aluminum hydroxide and 28g of acetylene black, add 15g of aluminum powder, and use absolute ethanol as the medium for ball milling for 5 hours at a speed of 300r / min. Dry after ball milling to obtain a precursor powder with fine particle size and uniform mixture of carbon and aluminum. Then put the precursor into a microwave high-temperature sintering furnace, set the temperature regime, and raise the temperature to 1350°C at a rate of 25°C / min under an ordi...

Embodiment 3

[0040] First, mix 100g of industrial aluminum hydroxide with 15g of ammonium chloride, add 50ml of deionized water, and perform wet ball milling for 30min at a ball milling speed of 300r / min. After ball milling, wash with boiling while stirring, the boiling time is 30min, the stirring speed is 300r / min, and suction filtration. Boil and wash five times as above, filter with suction, and dry to obtain a mixture of treated ammonium chloride and aluminum hydroxide. Then take 100g of the treated mixture of ammonium chloride and aluminum hydroxide and mix it with 23g of acetylene black, add 25g of aluminum powder, and ball mill it with absolute ethanol for 5 hours at a speed of 300r / min. Dry after ball milling to obtain a precursor powder with fine particle size and uniform mixture of carbon and aluminum. Then put the precursor into a microwave high-temperature sintering furnace, set the temperature regime, and raise the temperature to 1300°C at a rate of 35°C / min in an ordinary ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com