Low-carbon aged steel and preparation method thereof

A aging steel and aging technology, applied in the field of metallurgy, can solve problems such as unreasonable material composition and heat treatment process, undeveloped low-carbon aging steel, and increased notch sensitivity, so as to achieve good cutting performance, increase hardness, and promote crystallization. The effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention provides the preparation method of the low-carbon aging steel described in the above scheme, comprising the following steps:

[0049] (1) batching, casting and heat preservation treatment are carried out sequentially according to the chemical composition to obtain a low-carbon aging steel slab;

[0050] (2) Hot forging and cooling the billet described in the step (1) successively to obtain a billet before aging;

[0051] (3) Machining and shaping the pre-aging billet in step (2), performing aging treatment, and then air-cooling to room temperature to obtain low-carbon aging steel.

[0052] According to the chemical composition, the invention sequentially performs batching, casting and heat preservation treatment to obtain the low-carbon aging steel slab. In the present invention, after batching according to the chemical composition, the vacuum furnace is preferably used for melting and casting. In the present invention, the vacuum degree of the v...

Embodiment 1

[0062] A preparation method of low-carbon aging steel: comprising steps as follows:

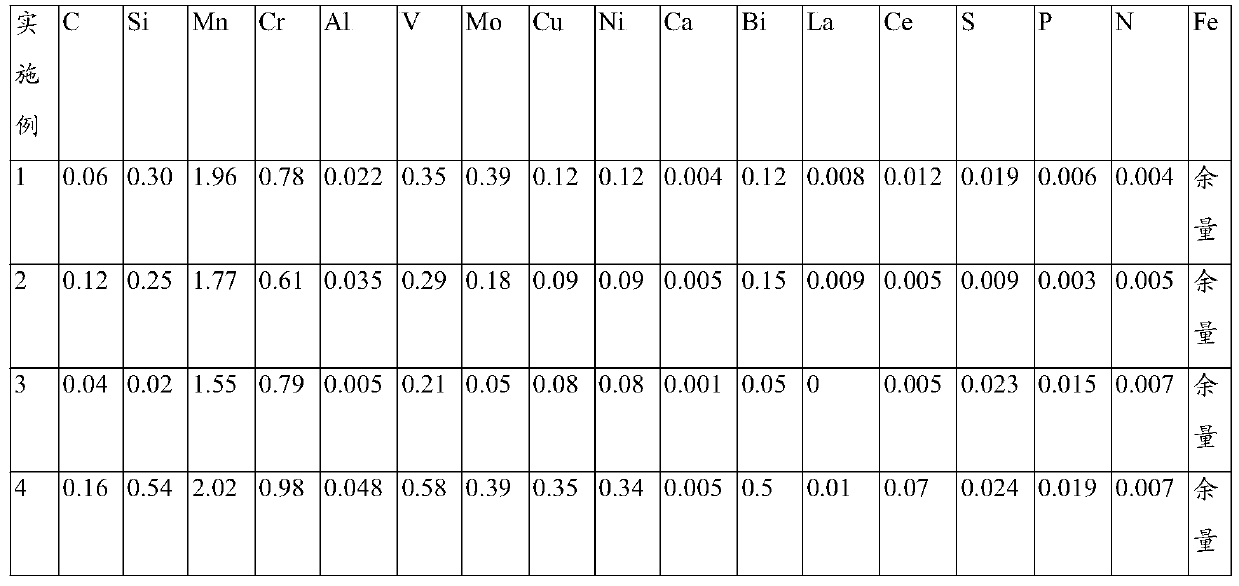

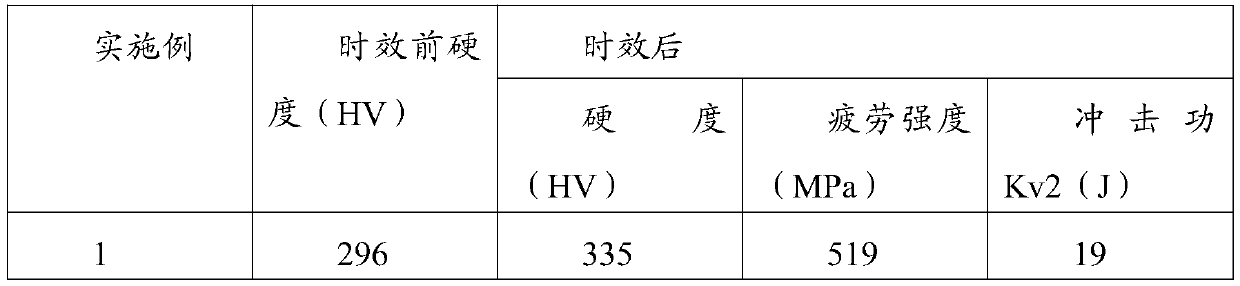

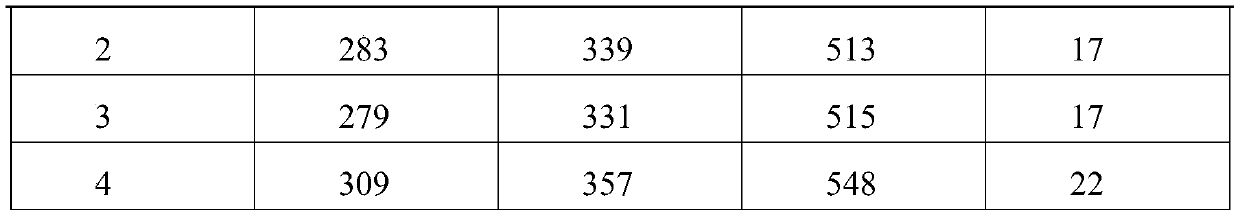

[0063] Dosing according to the alloy composition in Table 1, smelting in a vacuum furnace, the vacuum degree is 0.1Pa, the melting temperature is 1548°C, the size of the cast slab is 300mm long × 250mm wide × 50mm thick, and the slab is kept at 1200°C for 30 Minutes later, hot forging to a thickness of 30mm, the temperature of the billet after hot forging is 865°C; the forged billet is cooled to 430°C at a cooling rate of 60°C / min, and then air-cooled to room temperature to obtain a billet before aging;

[0064] Cut a 20×20×250 mm sample from the pre-aging billet, heat the sample to 630° C. and keep it warm for 80 minutes to complete the aging heat treatment, and then air-cool to room temperature to obtain a square columnar part of low carbon aging steel.

Embodiment 2

[0066] A kind of low-carbon aging steel, according to the alloy composition in Table 1, the preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com