High reactivity coke and its production method

A high-reactivity coke and production method technology, applied in coking ovens, petroleum industry, etc., can solve the problems of unfavorable operation of blast furnaces and less application research, and achieve the effects of low price, wide sources, and reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

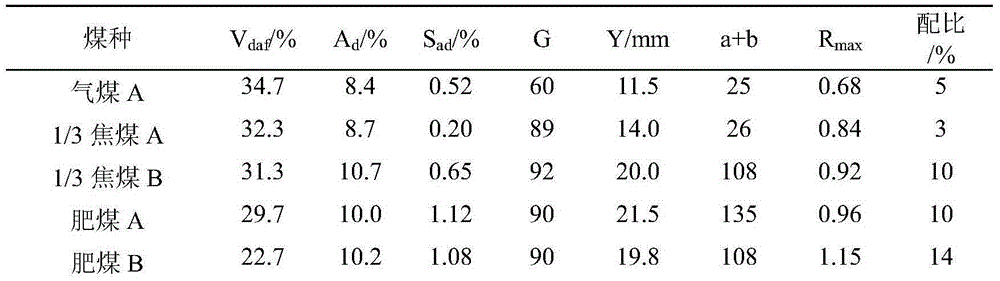

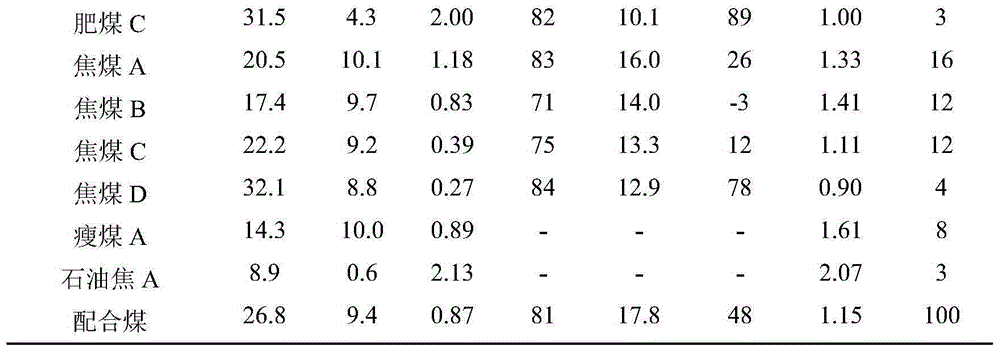

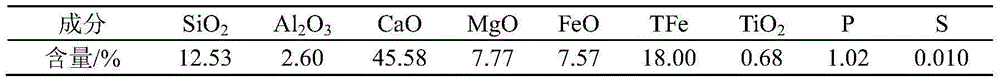

[0031] The selection of each single coal and the coal blending scheme in Examples 1-4 are the same as those in Comparative Example, and the composition of the added steel slag is shown in Table 2.

[0032] Table II

[0033]

[0034] The steel slag was evenly mixed into the blended coal, and then the same 40kg coke oven coking test as that of the comparative example was carried out, and the detection method of the obtained coke was also the same as that of the comparative example. The particle size and amount of steel slag mixed into the blended coal are shown in Table 3.

[0035] Table three

[0036]

[0037] The properties of the cokes prepared in Comparative Examples and Examples 1-4 are shown in Table 4.

[0038] Table four

[0039]

[0040] As can be seen from the data in Tables 3 and 4, for the cokes of Examples 1-4, steel slag was added during coking, and the addition of steel slag made the coke strength index M 40 , M 10 And the ash and sulfur content have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com