Method for rapidly synthesizing pure-phase small-grain ZSM-11 molecular sieve

A technology of ZSM-11 and small crystal grains, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of unfavorable industrial production and long crystallization time, and achieve the synthesis time Short, easy-to-handle, low-sodium effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

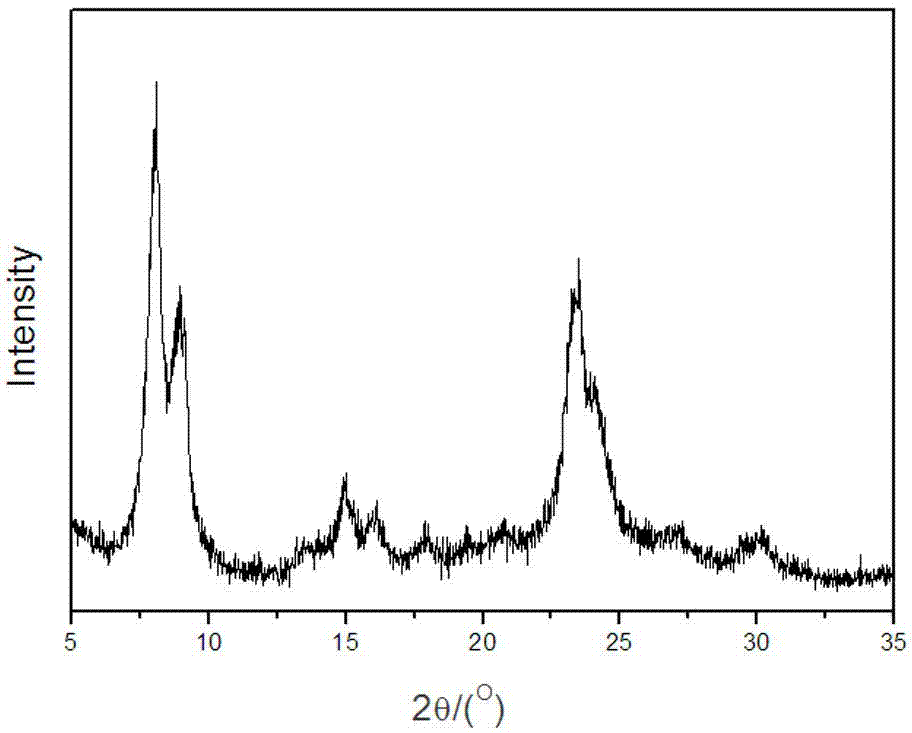

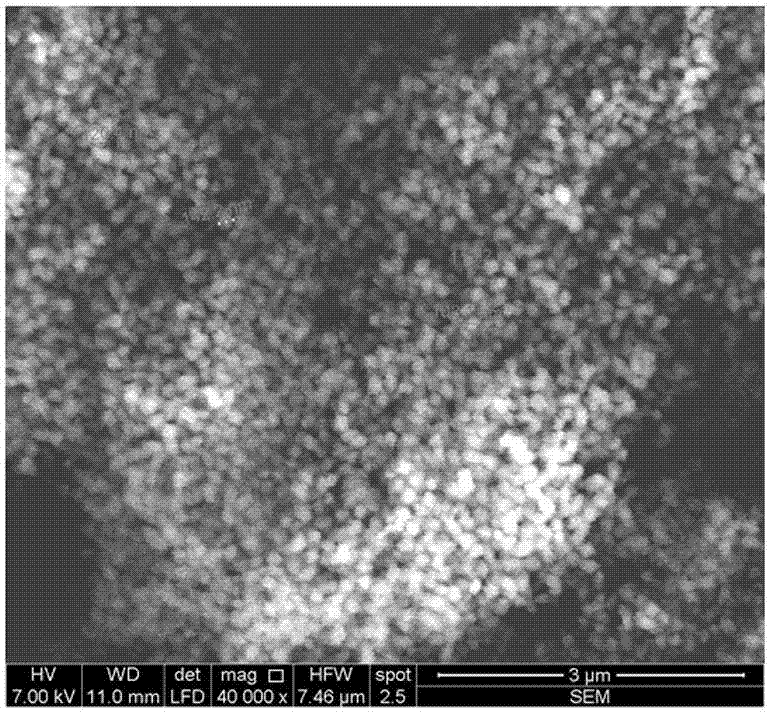

[0019] First, dissolve 1.77 g of aluminum sulfate octadecahydrate in 120 g of deionized water, then add 10 g (30 wt %) of tetrabutylammonium hydroxide aqueous solution and 10.41 g of 1,8-octanediamine in sequence, stir until dissolved, and finally, under stirring, add 52.00 g silica sol solution (SiO 2 30wt%), after adding, continue to stir for 4h to make it evenly mixed, and the composition of the amount of substance of the reaction sol is Al 2 o 3 : SiO 2 : R1 : R2 : H 2 O=0.01: 1: 0.04: 0.28:35, R1 is tetrabutylammonium hydroxide, R2 is 1,8-octyldiamine. The above reaction sol was sealed in a 250 ml stainless steel autoclave lined with polytetrafluoroethylene, and crystallized at 160 °C for 1 day. Wash until neutral, dry overnight at 100°C to obtain the product, which is the crystal phase structure of ZSM-11 molecular sieve with pure phase and small crystal grains as tested by X-ray diffraction (XRD). The X-ray diffraction (XRD) diagram of the sample is shown in the ...

Embodiment 2

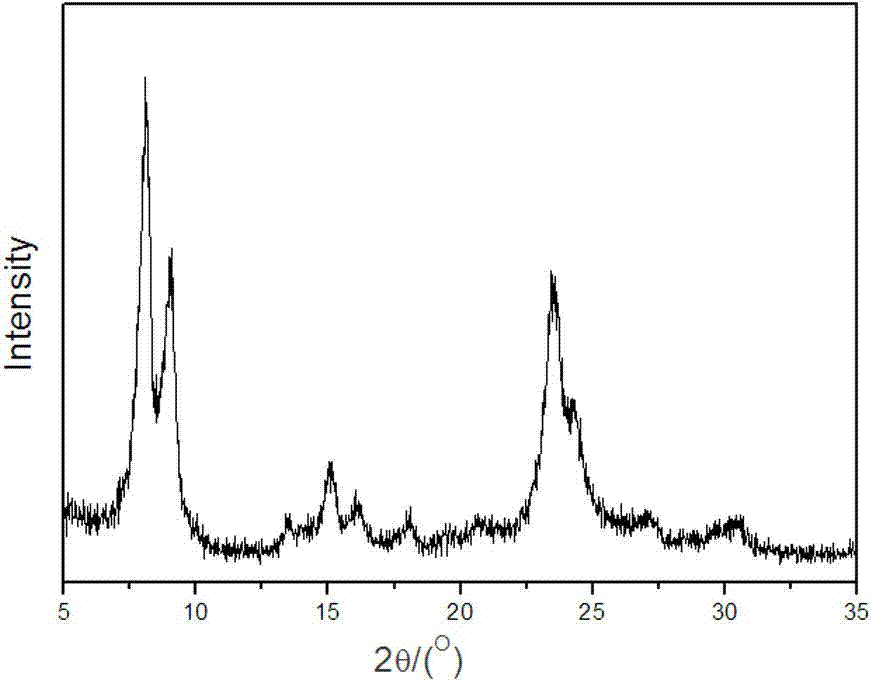

[0021] First, dissolve 0.89g of aluminum sulfate octadecahydrate in 100g of deionized water, then add 6.54g (30 wt%) tetrabutylammonium hydroxide aqueous solution and 8.78g of 1,8-octanediamine in sequence, stir until dissolved, and finally, under stirring , adding 52.00 g of silica sol solution (SiO 2 30wt%), after adding, continue to stir for 4h to make it evenly mixed, and the composition of the amount of substance of the reaction sol is Al 2 o 3 : SiO 2 : R1 : R2 : H 2 O=0.0050: 1 : 0.026 : 0.24 :30, R1 is tetrabutylammonium hydroxide, R2 is 1,8-octanediamine. The above reaction sol was sealed in a 250 ml stainless steel autoclave lined with polytetrafluoroethylene, and crystallized at 160 °C for 2 days. Wash until neutral, dry overnight at 100°C to obtain the product, which is the crystal phase structure of ZSM-11 molecular sieve with pure phase and small crystal grains as tested by X-ray diffraction (XRD). The X-ray diffraction (XRD) diagram of the sample is shown...

Embodiment 3

[0023] First, dissolve 0.51 g of sodium metaaluminate in 110 g of deionized water, then add 4 g (30 wt %) of tetrabutylammonium hydroxide aqueous solution and 9.41 g of 1,8-octyldiamine in sequence, stir until dissolved, and finally add 52.00 g of g silica sol solution (SiO 2 30wt%), after adding, continue to stir for 4h to make it evenly mixed, and the composition of the amount of substance of the reaction sol is Al 2 o 3 : SiO 2 : R1 : R2 : H 2 O=0.0125: 1 : 0.016 : 0.255 :31.9, R1 is tetrabutylammonium hydroxide, R2 is 1,8-octanediamine. The above reaction sol was sealed in a 250 ml stainless steel autoclave lined with polytetrafluoroethylene, and crystallized at 160 °C for 1 day. Wash until neutral, and dry at 100°C overnight to obtain the product. It is the crystal phase structure of the pure-phase small-grain ZSM-11 molecular sieve through X-ray diffraction (XRD). The X-ray diffraction (XRD) diagram of the sample is shown in the attached Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com