Rare earth and sodium humate compound feed additive and preparation method thereof

A technology of sodium humate and compound feed, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of reducing the cost of feed, not promoting the activation and absorption of feed ingredients, and not having the ability to effectively prevent and control various diseases, so as to reduce the cost of feed , Low residue, the effect of promoting activation and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Air-dry the weathered coal and crush it into more than 40 mesh

[0026] 2. Alkali solution treatment:

[0027] Add 100 catties of weathered coal above with 1200 catties of 1% sodium hydroxide solution, stir and leach, let it stand for about 24 hours, discard the precipitate, the soy sauce-like solution in the upper layer is sodium humate solution, and further remove iron to obtain Sodium humate solution for porcelain.

[0028] 3. Acid analysis treatment

[0029] Add appropriate amount of sulfuric acid or hydrochloric acid to the solution for acid analysis. At this time, the humic acid is in a gel state and precipitates out from the solution. The mixture was allowed to settle for 24 hours to separate by itself. Separate and remove the upper layer of acid water, and precipitate water several times to remove acid anions and soluble iron ions. Then take out the humic acid and let it dry.

[0030] 4. Purification of humic acid

[0031] Put the dried humic acid in a ...

Embodiment 3

[0038] Divide 10 fattening sheep into 2 groups and compare the addition of the compound feed additive of the present invention and no addition in their feed.

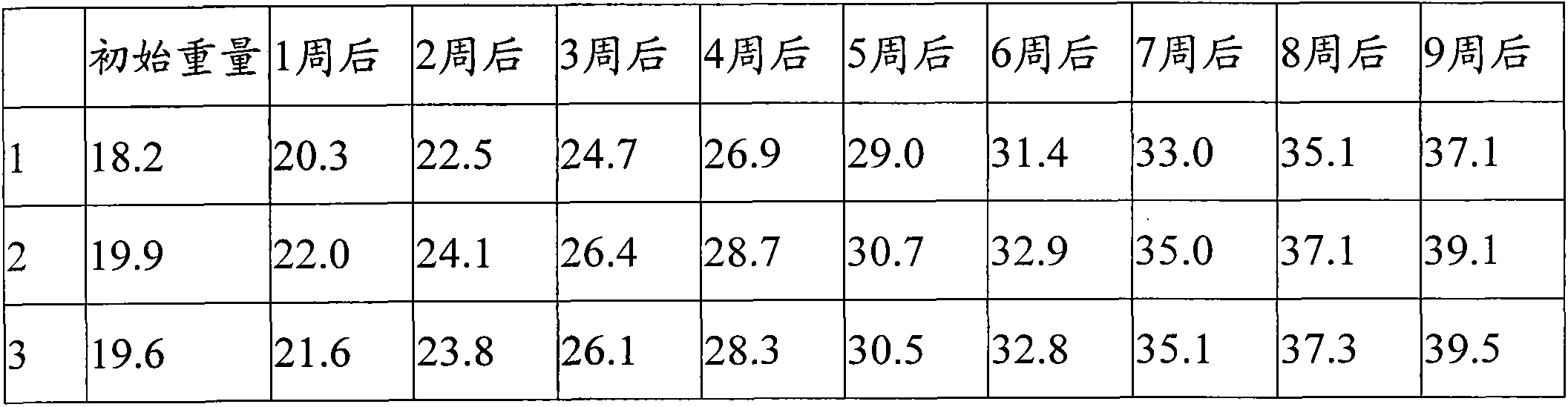

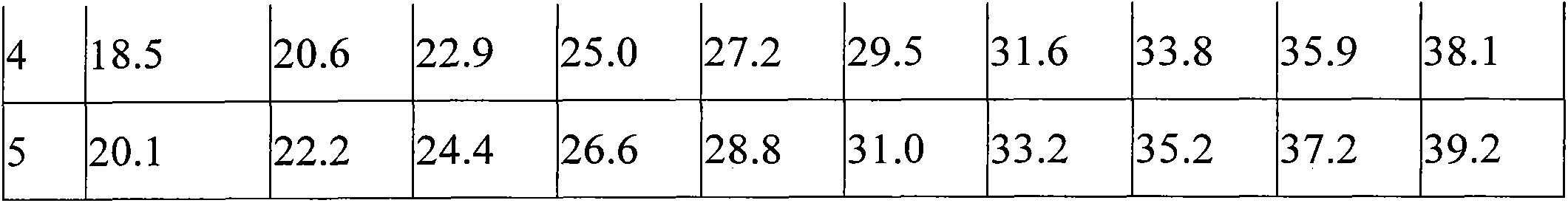

[0039] Feed and add compound additive feed of the present invention Unit: (kg)

[0040]

[0041] Feed without additives Unit: (kg)

[0042]

[0043]

[0044] From the comparison, it can be clearly seen that the fattening sheep can increase the weight gain by more than 20% after using the additive of the invention, compared with that without adding feed.

[0045] 5 groups (every group of 5) lambs with diarrhea were fed with different proportions of this compound feed additive feed for 3 weeks and carried out weighing observations every week, and the initial total weight of each group was listed in the header of each group.

[0046] 29.5

[0047] The diarrhea of each group of sheep basically recovered at the end, but it was obvious that the lambs recovered early and their weight increased ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com