Method for preparing battery-grade iron phosphate and industrial-grade lithium phosphate in waste lithium iron phosphate battery

A lithium iron phosphate battery and lithium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems that have not been seen yet, meet high environmental protection recycling requirements, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

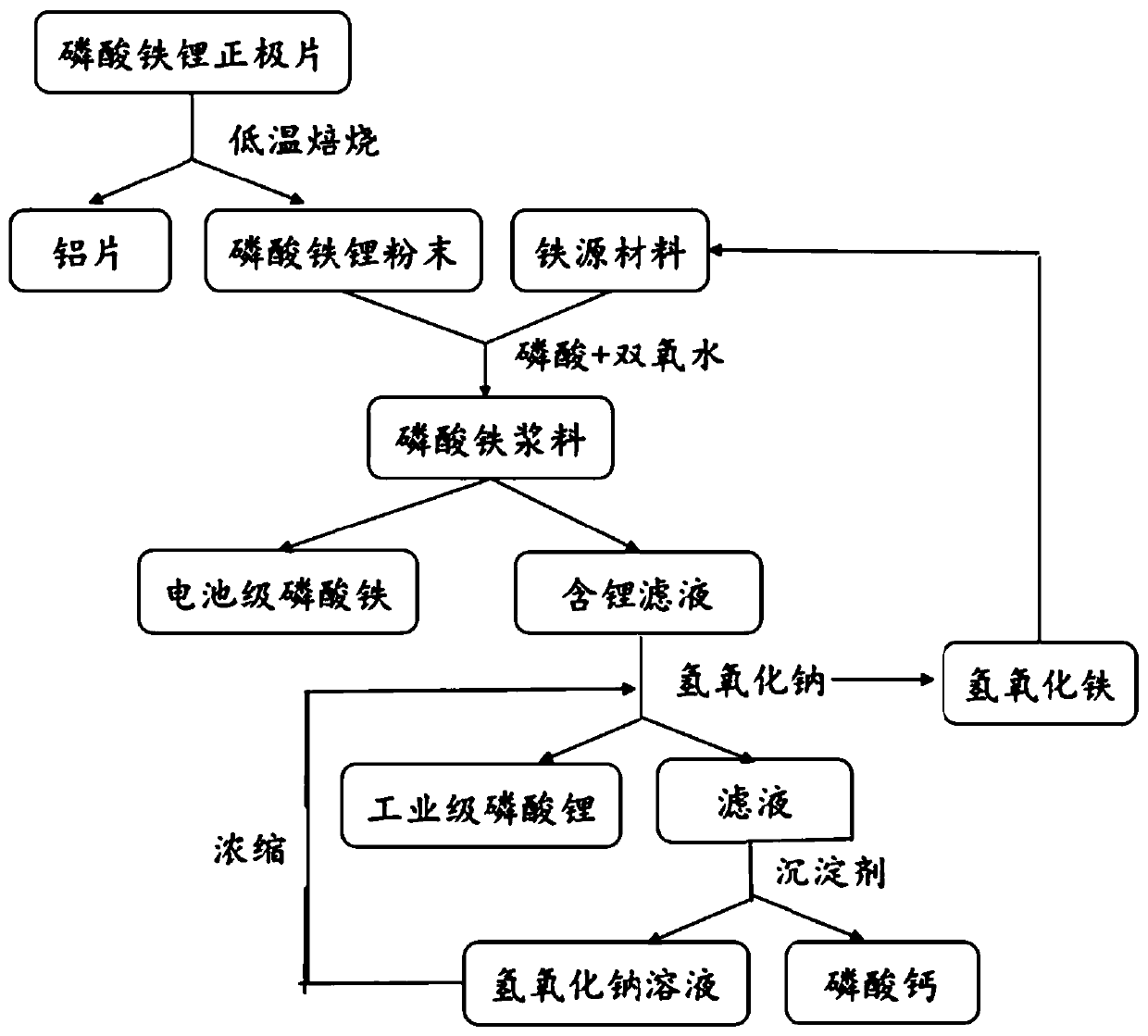

Method used

Image

Examples

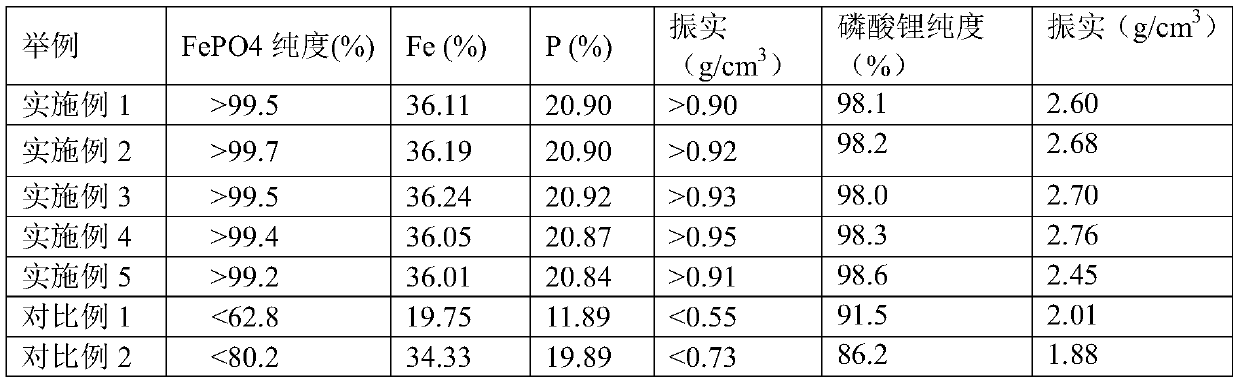

Embodiment 1

[0035] (1) Disassemble the waste lithium iron phosphate battery, and sort out the positive pole piece; after cleaning, put it in a heating furnace at 200 ° C, and bake it for 3 hours; take out the pole piece, mechanically crush it, and sieve it to obtain aluminum flakes and lithium iron phosphate-based positive electrode material;

[0036] (2) Get 200 g of the positive electrode material obtained and mix it with 46 g of ferrous oxide, and add it to 1.34 L of a 15% mass fraction of phosphoric acid solution and hydrogen peroxide mixed solution; add water and dilute it and stir it in a water bath at 80° C. for 4 hours to obtain ferric phosphate slurry;

[0037] (3) Wash and filter the ferric phosphate slurry obtained in (2), dry the obtained ferric phosphate filter cake and dehydrate at 500° C. for 4 hours to obtain battery-grade ferric phosphate; after the filtrate is concentrated and evaporated 4 times, keep the solution temperature at 80 ℃, after adding sodium hydroxide solut...

Embodiment 2

[0040] (1) Disassemble the waste lithium iron phosphate battery, and sort out the positive pole piece; after cleaning, put it in a heating furnace at 400 ° C, and bake it for 5 hours; take out the pole piece, mechanically crush it, and sieve it to obtain aluminum flakes and lithium iron phosphate-based positive electrode material;

[0041] (2) Mix 500 g of the positive electrode material obtained with 508 g of ferric hydroxide, and add it to 4.2 L of 20% phosphoric acid solution and hydrogen peroxide mixed solution; dilute with water and stir for 2 h in a water bath at 50° C. to obtain ferric phosphate slurry;

[0042] (3) Wash and filter the ferric phosphate slurry obtained in (2), dry the obtained ferric phosphate filter cake and dehydrate at 400°C for 6 hours to obtain battery-grade ferric phosphate; after the filtrate is concentrated and evaporated twice, keep the solution temperature at 90 ℃, after adding sodium hydroxide solution, adjust the pH to 4.5, and iron hydroxid...

Embodiment 3

[0045] (1) Disassemble the waste lithium iron phosphate battery, and sort out the positive pole piece; after cleaning, put it in a heating furnace at 500°C, and roast it for 1.5h; take out the pole piece, mechanically crush it, and sieve to obtain aluminum pieces and lithium iron phosphate as The main positive electrode material;

[0046] (2) Take 1000 g of the positive electrode material obtained and mix it with 177 g of iron, and add it to 1.16 L of a 20% mass fraction of phosphoric acid solution and hydrogen peroxide mixed solution; add water to dilute it and stir it in a water bath at 95° C. for 1 h to obtain ferric phosphate slurry ;

[0047] (3) Wash and filter the ferric phosphate slurry obtained in (2), dry the obtained ferric phosphate filter cake and dehydrate at 700°C for 1 hour to obtain battery-grade ferric phosphate; after the filtrate is concentrated and evaporated 10 times, keep the solution temperature at 50 ℃, after adding sodium hydroxide solution, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com