Method and device for preparing mass spectrum level acetonitrile

A mass spectrometry, acetonitrile technology, applied in the purification/separation of carboxylic acid nitrile, organic chemistry and other directions, can solve the problems of many impurity interference peaks, the purity does not meet the detection requirements of pesticide residues, etc., achieves simple operation, wide market application prospects, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

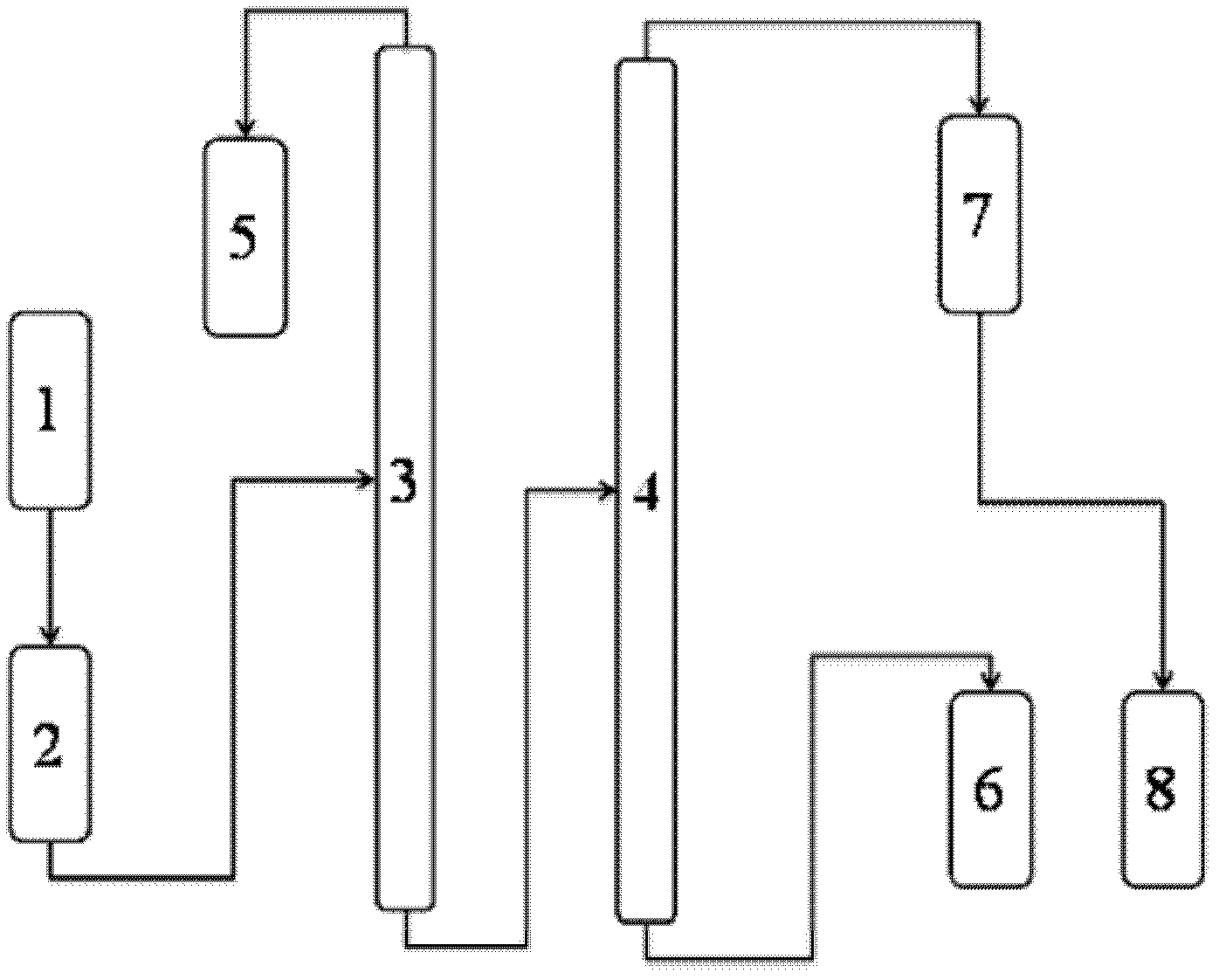

Method used

Image

Examples

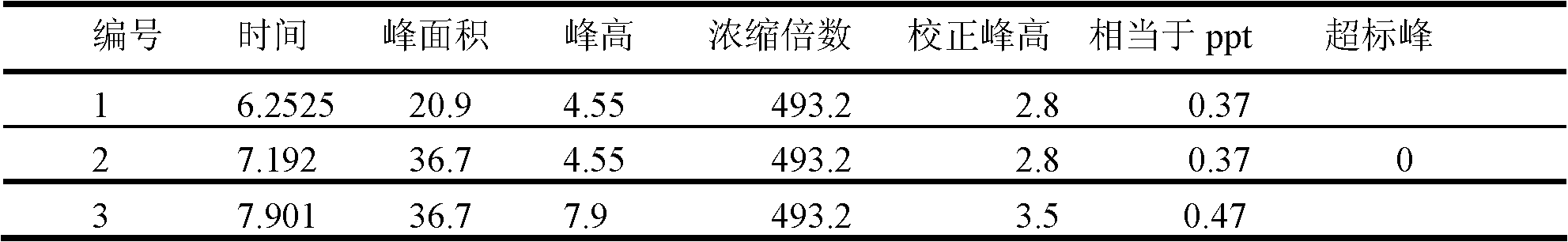

Embodiment 1

[0068] 1. Oxidation

[0069] 2. Chromatography or adding sulfuric acid (choose one of the two)

[0070] Pass the acetonitrile raw material through two columns equipped with acidic alumina and activated carbon to remove allyl alcohol, oxazole and a certain amount of water. Or adding sulfuric acid can also remove allyl alcohol and oxazole, and can also neutralize a small amount of lye in the oxidation process.

[0071] Part of the preceding liquid was discarded and the remaining solvent was collected for a rectification step.

[0072] 3. Distillation

[0073] By optimizing the distillation conditions, the desired product is finally obtained.

[0074] Device parameters

[0075] 1) Oxidation reaction tank: the volume is 2000 liters.

[0076] Oxidation reagent: potassium permanganate (Beijing Chemical Reagent Factory), the purity is 98%, and the consumption of high-efficiency oxidation reagent is 22% of raw material weight.

[0077] 2) Dehydrogenation tower: tower height 6m, ...

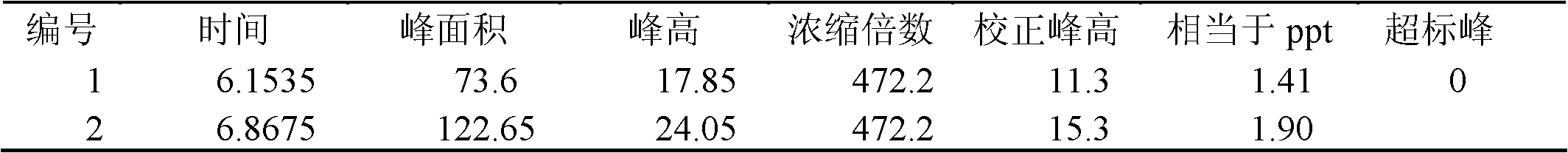

Embodiment 2

[0110] Device parameters

[0111] 1) Oxidation reaction tank: glass separatory funnel, volume 2.5 liters.

[0112] Oxidation reagent: potassium permanganate (Beijing Chemical Reagent Factory), the concentration is 98%; the consumption of potassium permanganate is 5% of raw material weight.

[0113]2) Dehydrogenation tower: the height of the glass tower is 1.3m, and the inner diameter of the tower is 10cm; packing: θ ring packing.

[0114] The condenser tube is a coiled glass condenser.

[0115] Dehydrogenation tower kettle: a 3-liter triangular round-bottom glass flask, heated by an electric heating pot.

[0116] 3) Distillation tower: the height of the glass tower is 1.5m, and the inner diameter of the tower is 10cm; packing: θ ring packing.

[0117] The condenser tube is a coiled glass condenser.

[0118] Rectification tower kettle: a 3-liter triangular round-bottom glass flask, heated by an electric heating pot.

[0119] 4) Filtration device: glass solvent filter, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com