Electronic grade hydrogen chloride purification method

A purification method and hydrogen chloride technology, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, chemical instruments and methods, etc., can solve problems such as high production cost, high equipment requirements, corrosion, etc., and achieve low production cost, simple operation, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

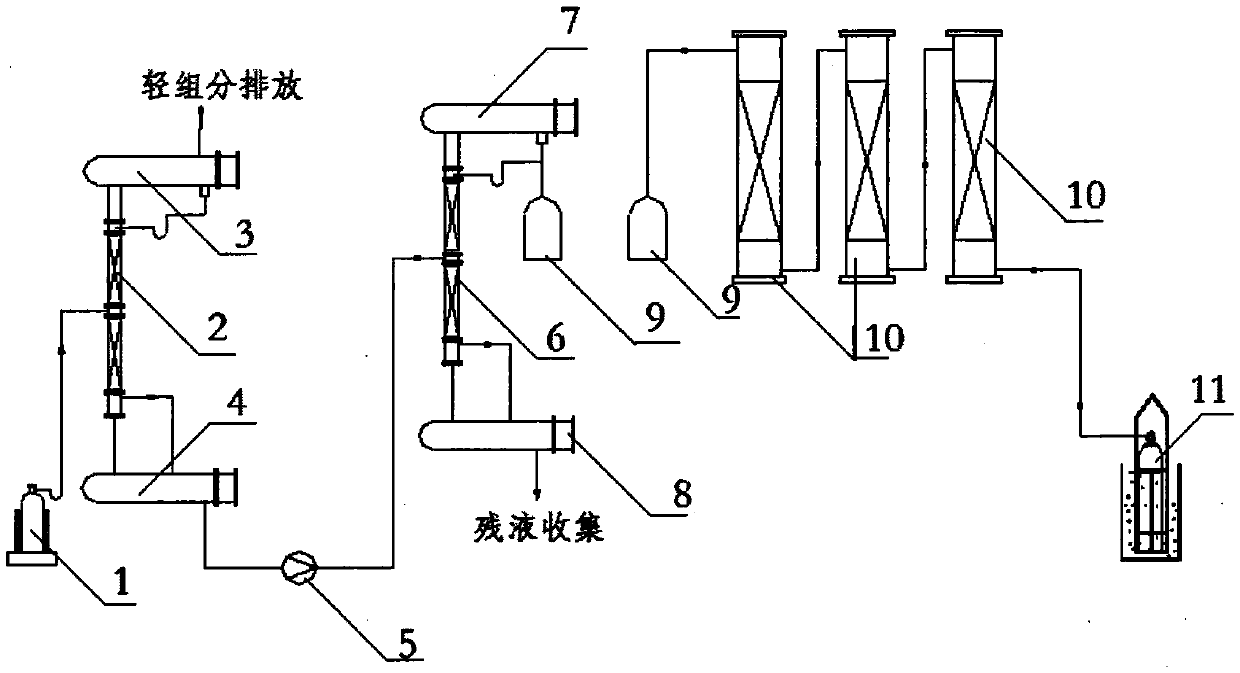

[0022] Such as figure 1 As shown, the specific steps of the purification method of the electronic grade hydrogen chloride of the present embodiment are:

[0023] The first step: introducing industrial-grade liquid hydrogen chloride with a purity of 99% to the middle position of the first rectification tower 2 for rectification, the first rectification tower 2 is a packed tower, and the fillers used are Hastelloy Raschig annular packing made of alloy material, the number of theoretical plates is 24, the rectification pressure is 10bar, the temperature at the top of the column is -20°C, the temperature at the bottom of the column is 10°C, the top of the first rectification column is connected to the first condenser 3. The bottom of the tower is connected to the first reboiler 4, and the first reboiler 4 is heated by an electric heating blanket. In the distillation tower 2, the uncondensed waste gas is discharged into the waste gas treatment system to remove light components suc...

Embodiment 2

[0027] Such as figure 1 As shown, the specific steps of the purification method of the electronic grade hydrogen chloride of the present embodiment are:

[0028] The first step: introducing industrial-grade liquid hydrogen chloride with a purity of 99% to the middle position of the first rectification tower 2 for rectification, the first rectification tower 2 is a packed tower, and the fillers used are Hastelloy The Pall annular packing made of alloy material has a theoretical plate number of 20, a rectification pressure of 12 bar, a tower top temperature of -25°C, and a tower bottom temperature of 0°C. The top of the first rectification column is connected to the first condenser 3. The bottom of the tower is connected to the first reboiler 4. The first reboiler 4 is heated by heat transfer oil. The hydrogen chloride gas generated by the heating of the first reboiler 4 is condensed by the first condenser 3 and then fully refluxed to the first rectification In tower 2, the unc...

Embodiment 3

[0032] Such as figure 1 As shown, the specific steps of the purification method of the electronic grade hydrogen chloride of the present embodiment are:

[0033] The first step: introducing industrial-grade liquid hydrogen chloride with a purity of 99% to the middle position of the first rectification tower 2 for rectification, the first rectification tower 2 is a packed tower, and the fillers used are Hastelloy The stepped annular packing made of alloy material has a theoretical plate number of 12, a rectification pressure of 15 bar, a tower top temperature of -30°C, and a tower bottom temperature of -10°C. The top of the first rectification column is connected to the first condenser 3. The bottom of the tower is connected to the first reboiler 4, and the first reboiler 4 is heated by an electric heating blanket. In the distillation tower 2, the uncondensed waste gas is discharged into the waste gas treatment system to remove light components such as nitrogen, oxygen, hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com