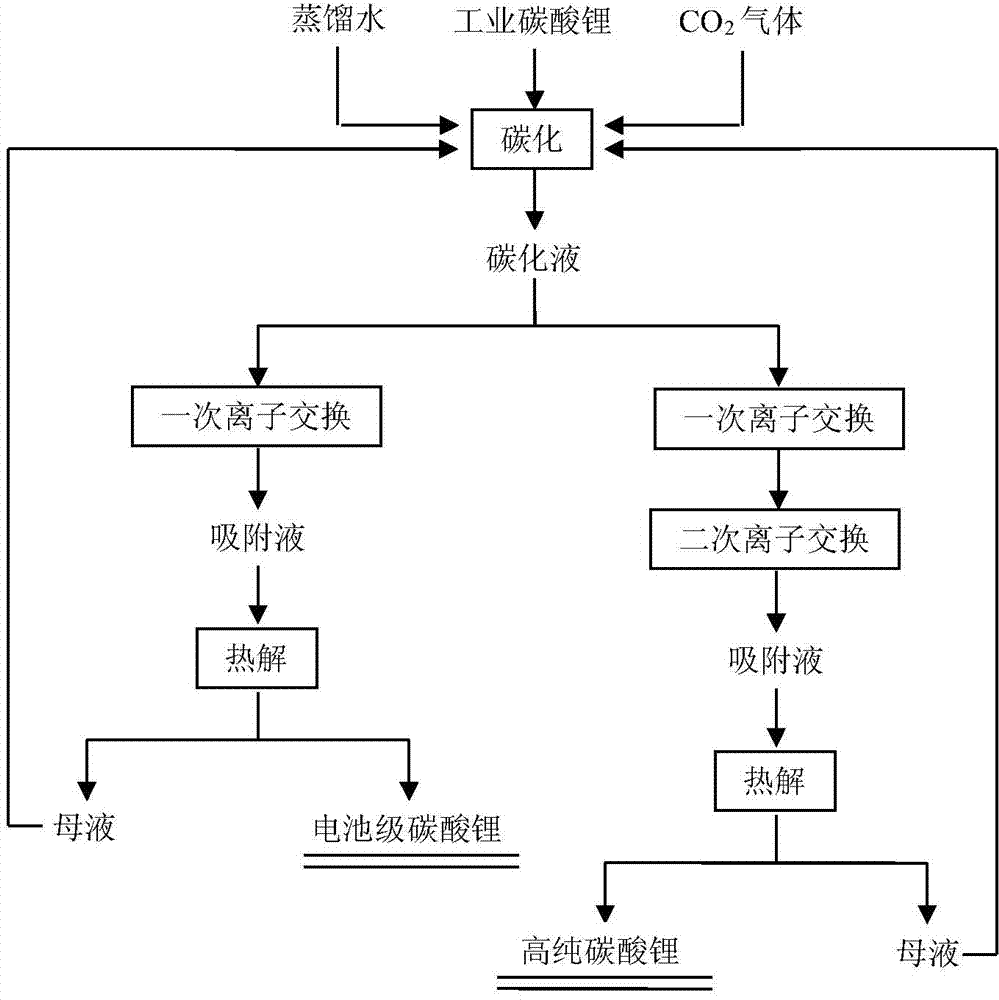

Method for preparing battery-grade lithium carbonate or high-purity lithium carbonate from industrial-grade lithium carbonate

A high-purity lithium carbonate, lithium carbonate technology, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of high impurity content, difficulty in further improving product purity, etc., achieving simple and easy process and increasing technology Content and added value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A certain industrial grade lithium carbonate, its composition is Li 2 CO 3 98.29%, Ca0.027%, Mg0.0055%, Na0.026%, K0.012%, Fe0.0015%, Cl0.009%, SO 4 2- 0.18%, hydrochloric acid insoluble matter 0.38%.

[0027] (1) At a liquid-solid ratio of 17.5, CO 2 Carry out carbonization test under the conditions of flow rate 40L / h, carbonization time 1.5h, and filter. Li + The loss rate in the solid phase was 1.52%, and the Ca in the filtrate 2+ 24mg / L, Mg 2+ 12mg / L.

[0028] (2) Pass the filtrate of (1) into the exchange column equipped with chelating resin, the flow rate is 0.8ml / min, and the removal rate of primary ion exchange calcium is 78%.

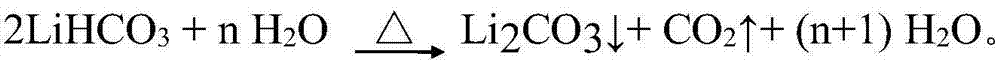

[0029] (3) Put the liquid after primary ion exchange into a three-necked flask with a stirrer, stir, heat until the material liquid boils, react for 1.5h, filter, wash, and dry to obtain lithium carbonate product.

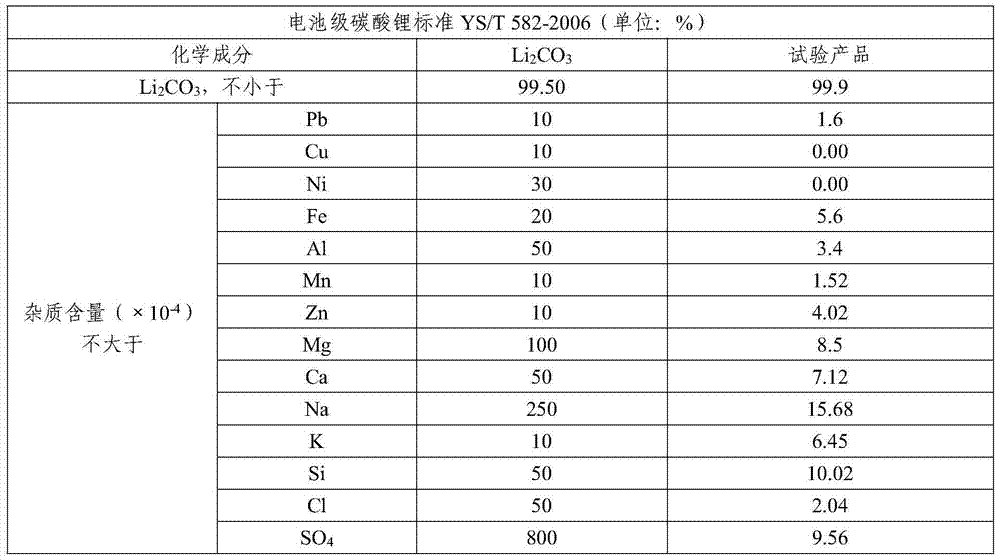

[0030] (4) After analysis, the content of lithium carbonate in the product is 99.9%, reaching the quality standard...

Embodiment 2

[0033] A certain industrial grade lithium carbonate, its composition is Li 2 CO 3 98.29%, Ca0.027%, Mg0.0055%, Na0.026%, K0.012%, Fe0.0015%, Cl0.009%, SO 4 2- 0.18%, hydrochloric acid insoluble matter 0.38%.

[0034] (1) At a liquid-solid ratio of 20, CO 2 Carry out carbonization test under the conditions of flow rate 45L / h, carbonization time 1h, and filter. Li + The loss rate in the solid phase was 1.09%, and the Ca in the filtrate 2+ 5.3mg / L, Mg 2+ 2.4mg / L.

[0035] (2) Pass the filtrate of (1) into the exchange column equipped with chelating resin, the flow rate is 1ml / min, the removal rate of calcium in the primary ion exchange is 80%, and the removal rate of calcium in the secondary ion exchange is 99%.

[0036] (3) Put the ion-exchanged solution into a three-necked flask with a stirrer, stir, heat until the material solution boils, react for 1 hour, filter, wash, and dry to obtain lithium carbonate product.

[0037] (4) After analysis, the content of lithium ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com