Method for producing potassium salt and sodium salt by using waste incineration fly ash

A technology for waste incineration fly ash and potassium salts, applied in the direction of alkali metal halide purification, etc., can solve the problems of low purity and separation of potassium chloride, and achieve the effect of high purity and yield, good repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

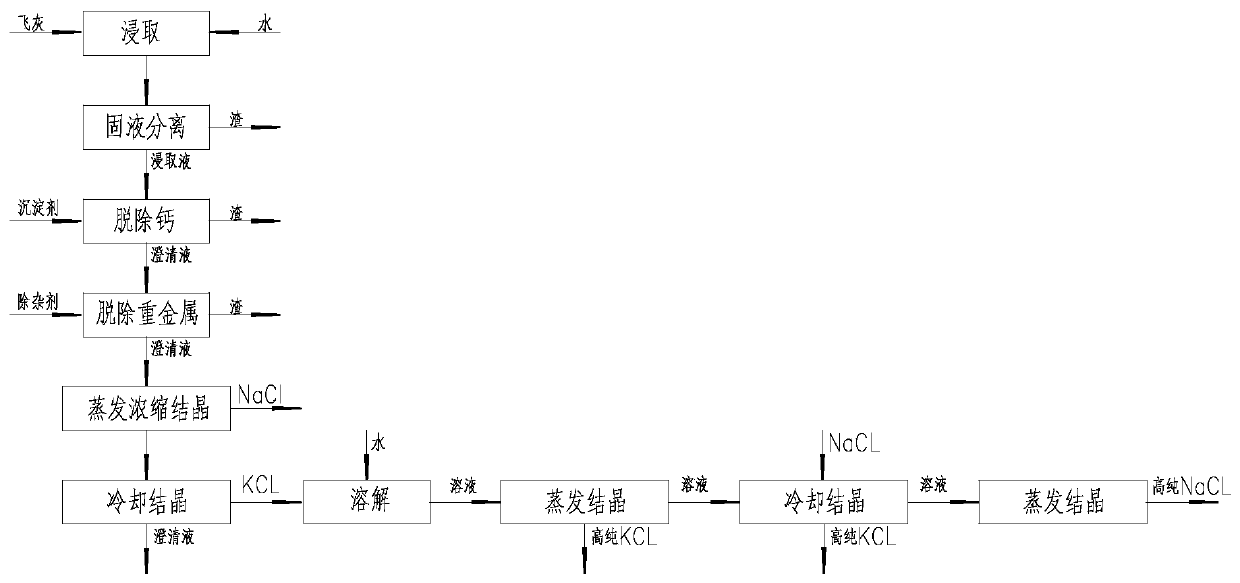

Method used

Image

Examples

Embodiment 1

[0033] (1) The waste incineration fly ash is leached with water. The conditions for leaching the fly ash with water are normal temperature and pressure, the leaching time is 0.5h, the liquid-solid ratio is 3, and the solid-liquid separation is obtained to obtain a mixture containing potassium chloride and sodium chloride. solution and residue. The mixed solution was used to leach fresh fly ash under the same conditions for several times continuously, and the number of consecutive leaching times was 5 times to obtain the leaching solution.

[0034] (2) Under normal temperature and pressure, add sodium carbonate to the leaching solution to remove calcium, the dosage of sodium carbonate is 20g / L, the reaction time is 2h, filter to obtain a clear solution.

[0035] (3) Add impurity remover polyacrylamide to the clarified liquid filtered out in step (2). The dosage of impurity remover is 0.3g / L to remove heavy metal impurities. The reaction time is 4h, and filter to obtain clarifie...

Embodiment 2

[0051] (1) The waste incineration fly ash is leached with water. The conditions for leaching the fly ash with water are normal temperature and pressure, the leaching time is 2 hours, the liquid-solid ratio is 5, and the solid-liquid separation is obtained to obtain a mixed solution containing potassium chloride and sodium chloride. and filter residue. The mixed solution was used to leach fresh fly ash under the same conditions for several times continuously, and the number of consecutive leaching times was 7 times to obtain the leaching solution.

[0052] (2) Under normal temperature and pressure, add precipitant sodium carbonate to the leaching solution to remove calcium, the amount of sodium carbonate added is 40g / L, react for 4 hours, filter to obtain a clear solution.

[0053] (3) Add impurity remover sodium sulfide to the clarified liquid filtered out in step (2) in an amount of 0.7 g / L to remove heavy metal impurities, react for 8 hours, and filter to obtain a clarified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com