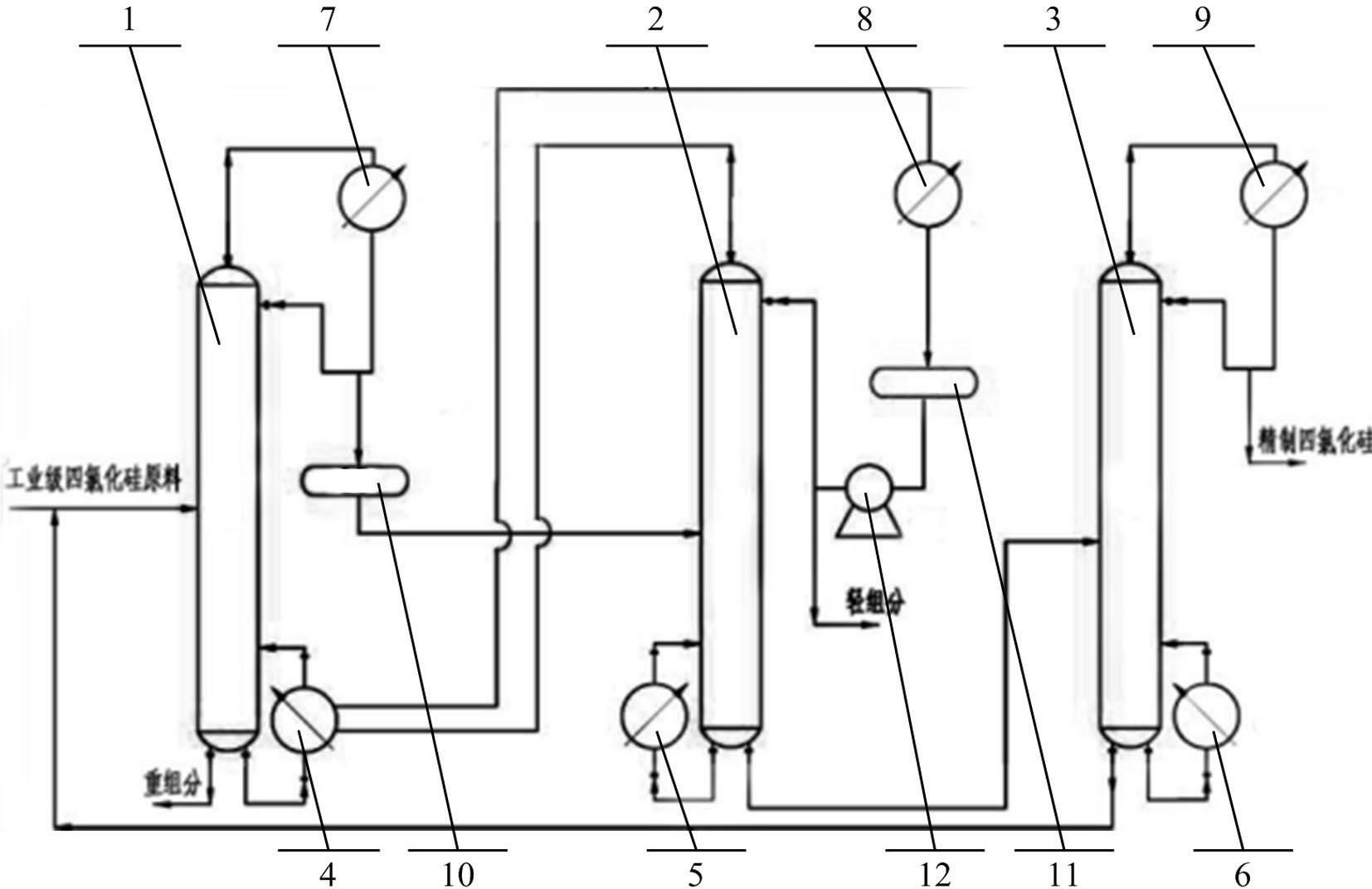

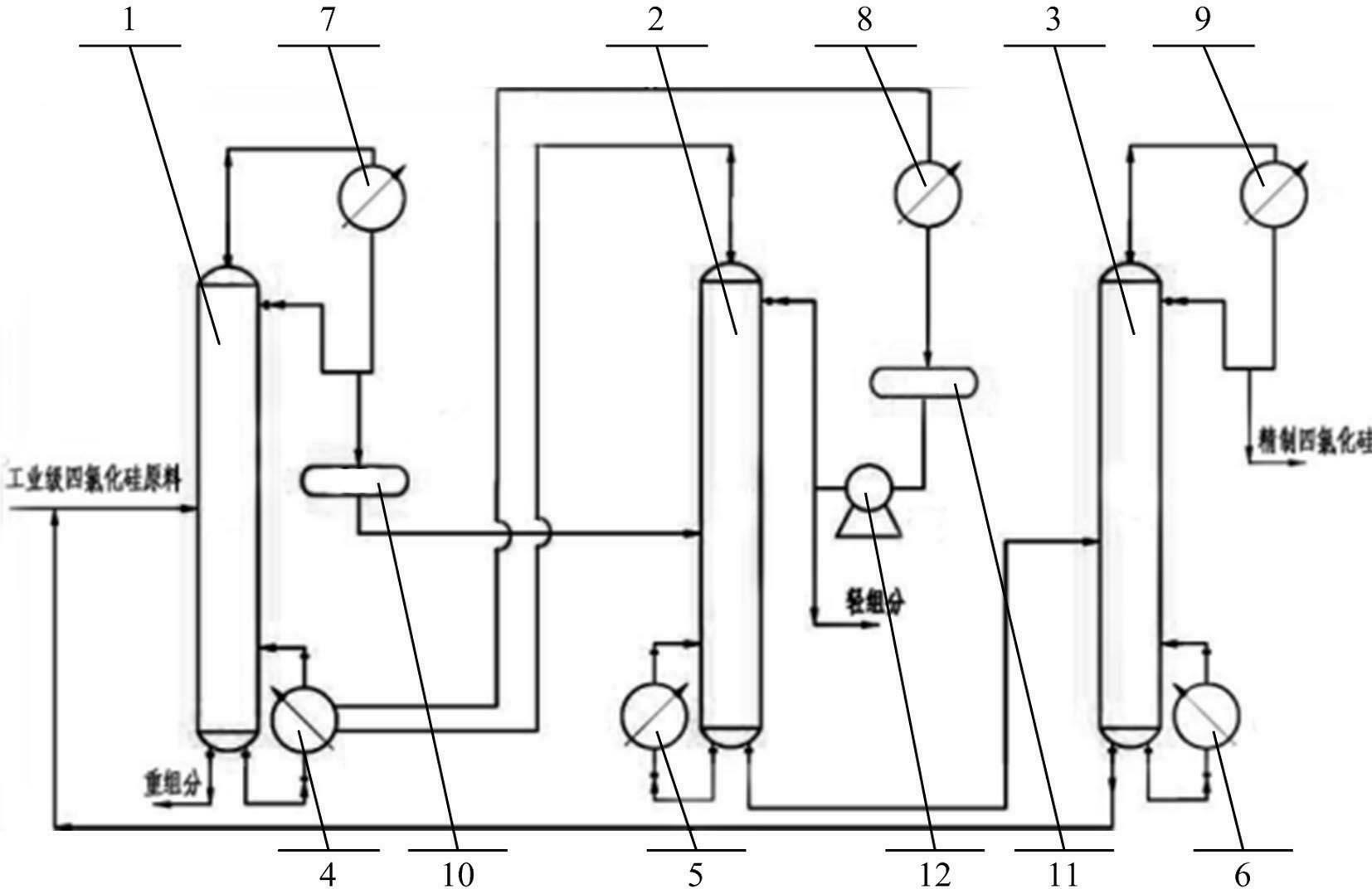

Processing process of industrial grade silicon tetrachloride

A technology of silicon tetrachloride and treatment process, applied in the directions of halogenated silicon compounds, halogenated silanes, etc., can solve the problems of pipeline blockage and high solid impurities, and achieve the effects of energy saving, wide application range and low raw material quality requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 85 (mass)% of crude silicon tetrachloride enters the weight removal tower at a flow rate of 2000kg / h, the temperature of the bottom of the tower is controlled at 75°C, the temperature of the top of the tower is controlled at 65°C, and the reflux ratio is 6:1. The gas phase at the top of the tower The material is transformed into a liquid phase through the condenser, and part of the obtained liquid phase material is returned to the weight removal tower, and part of it is extracted as a primary product and enters the buffer tank at a flow rate of 1700kg / h, and a part of the material in the tower tank is returned to the weight removal tower through a reboiler , the other part is extracted, and the output from the tower kettle is high-boiling viscous substances such as polymers and complexes, as well as solid impurities. The primary product in the buffer tank is pumped into the light removal tower. The temperature of the tower bottom is controlled at 90°C, the temperature of...

Embodiment 2

[0020] 95 (mass)% of crude silicon tetrachloride enters the weight removal tower at a flow rate of 2000kg / h, the temperature of the tower bottom is controlled at 100°C, the temperature of the tower top is controlled at 88°C, the reflux ratio is 20:1, and the gaseous phase material at the top of the tower After being transformed into a liquid phase by the condenser, part of the obtained liquid phase material is refluxed in the weight-removing tower, and part of it is extracted as a primary product and enters the buffer tank at a flow rate of 1700kg / h. The other part is extracted, and the output from the tower kettle is high-boiling viscous substances such as polymers and complexes, as well as solid impurities. The primary product in the buffer tank is then pumped into the light removal tower. The temperature of the tower kettle is controlled at 114°C, the temperature of the tower top is controlled at 85°C, the pressure of the tower top is 0.37MPa, and the reflux ratio is 150:1. ...

Embodiment 3

[0022] 90 (mass)% of crude silicon tetrachloride enters the weight removal tower at a flow rate of 2000kg / h, the temperature of the bottom of the tower is controlled at 120°C, the temperature of the top of the tower is controlled at 100°C, the reflux ratio is 24:1, and the gas phase material at the top of the tower After being transformed into a liquid phase by the condenser, part of the obtained liquid phase material is refluxed in the weight-removing tower, and part of it is extracted as a primary product and enters the buffer tank at a flow rate of 1700kg / h. The other part is extracted, and the output from the tower kettle is high-boiling viscous substances such as polymers and complexes, as well as solid impurities. The primary product in the buffer tank is then pumped into the light removal tower. The temperature of the tower bottom is controlled at 135°C, the temperature of the top of the tower is controlled at 100°C, the pressure of the top of the tower is 0.45MPa, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com