Production method of electronic-grade sulphuric acid

A sulfuric acid production, electronic-grade technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as high energy consumption and the difficulty of sulfuric acid reaching electronic-grade standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

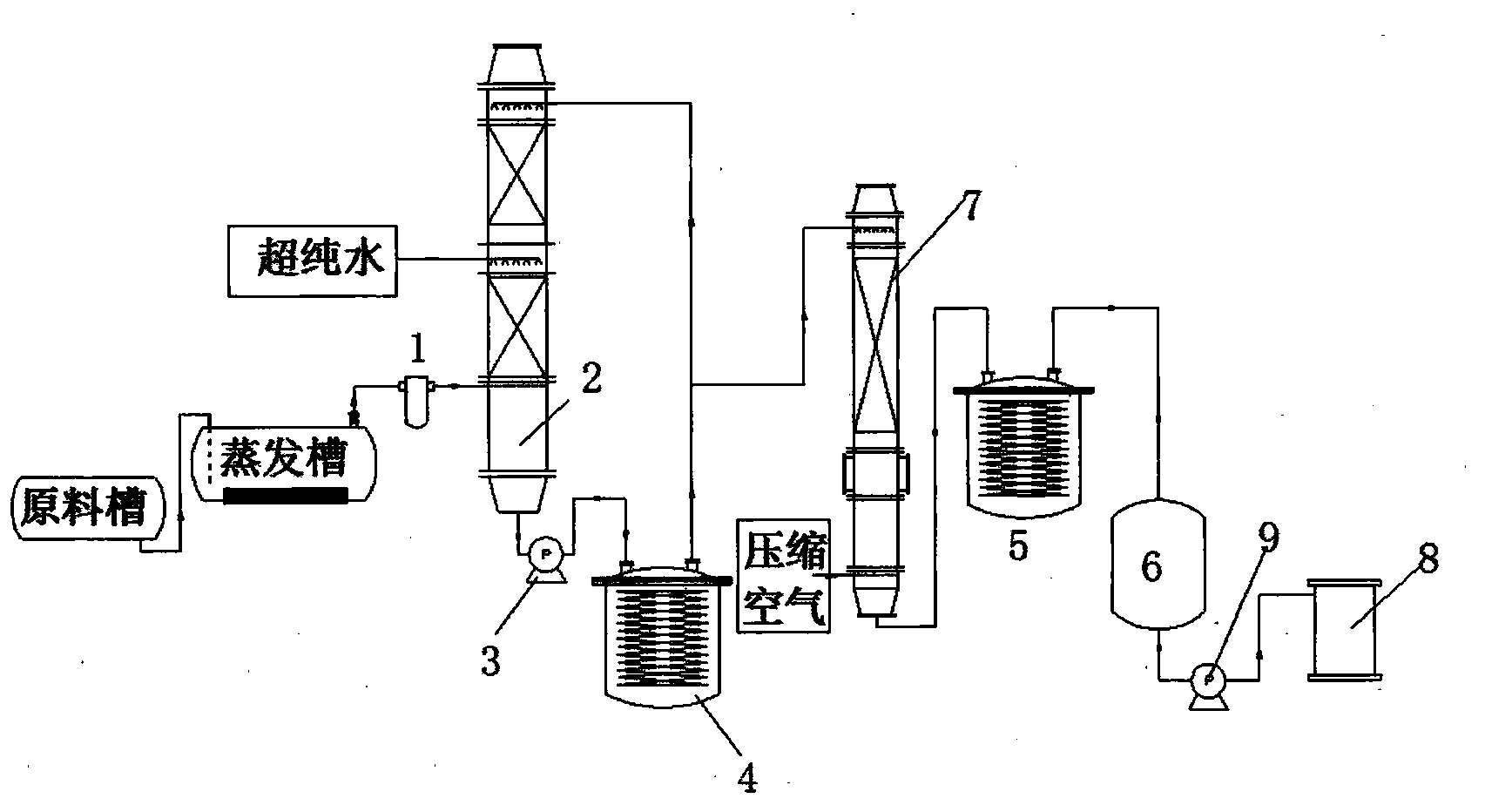

[0038] see figure 1 , the implementation steps of embodiment 1 are as follows:

[0039] 1): Provide industrial-grade sulfur trioxide raw materials into the raw material storage tank;

[0040] 2): The above-mentioned sulfur trioxide raw material is transported into the evaporation tank with a centrifugal pump;

[0041] 3): Use hot water to heat the evaporation tank, the heating temperature is controlled at 60°C, and the sulfur trioxide vapor generated by heating enters the absorption tower 2 after passing through the first filter 1;

[0042] 4): In the adsorption tower 2, the sulfur trioxide vapor is absorbed with electronic grade ultrapure water, and the concentration of the absorption solution is adjusted to be 97% ± 0.5% by controlling the flow rate of the sulfur trioxide vapor and the flow rate of the ultrapure water, and the absorption tower The temperature of 2 is controlled at 100°C, and the absorbed solution enters the degassing tower 7 after being cooled by the first...

Embodiment 2

[0048] see figure 1 , the implementation steps of embodiment 2 are as follows:

[0049] 1): Provide industrial-grade sulfur trioxide raw materials into the raw material storage tank;

[0050] 2): press the above-mentioned sulfur trioxide raw material into the evaporation tank with nitrogen;

[0051] 3): Use steam to heat the evaporation tank, the heating temperature is controlled at 70°C, and the sulfur trioxide steam generated by heating enters the absorption tower 2 after passing through the first filter 1;

[0052] 4): In the adsorption tower 2, the sulfur trioxide vapor is absorbed with electronic grade ultrapure water, and the concentration of the absorption solution is adjusted to be 97% ± 0.5% by controlling the flow rate of the sulfur trioxide vapor and the flow rate of the ultrapure water, and the absorption tower The temperature of 2 is controlled at 95°C, and the absorbed solution enters the degassing tower 7 after being cooled by the first cooler 4, and the outle...

Embodiment 3

[0058] see figure 1 , the implementation steps of embodiment 3 are as follows:

[0059] 1): Provide industrial-grade sulfur trioxide raw materials into the raw material storage tank;

[0060] 2): The above-mentioned sulfur trioxide raw material is transported into the evaporation tank with a centrifugal pump;

[0061] 3): Using electric heating wire to heat the evaporation tank, the heating temperature is controlled at 50°C, and the sulfur trioxide vapor generated by heating passes through the first filter 1 and then enters the absorption tower 2;

[0062] 4): In the adsorption tower 2, the sulfur trioxide vapor is absorbed with electronic grade ultrapure water, and the concentration of the absorption solution is adjusted to be 97% ± 0.5% by controlling the flow rate of the sulfur trioxide vapor and the flow rate of the ultrapure water, and the absorption tower The temperature of 2 is controlled at 85°C, and the absorbed solution enters the degassing tower 7 after being cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com