Method for catalytically synthesizing diethoxymethane by ionic liquid

A technology of ionic liquids and cations, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of deactivation, low yield of target products, easy carbon deposition on the surface of catalysts, etc., and achieve mild reaction conditions, The effect of low corrosion and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

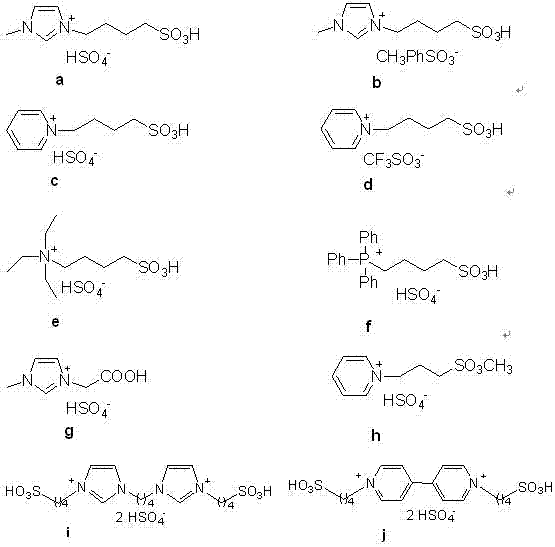

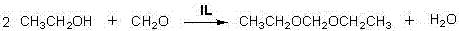

Method used

Image

Examples

Embodiment 1

[0038] In a 100mL autoclave, add 4.3g / 0.1mol (70%) formaldehyde solution, 0.73g / 2.3mmol ionic liquid a and 13.6g / 0.3mol ethanol successively, close the reactor, and use 1.0MPa of N 2 Replace the air in the reaction system, fill with N 2 to 1.0MPa. Stir and heat up to 120 within 30 minutes o C, react for 1h under the condition of 2.0 MPa. After the reaction is completed, cool to room temperature and release the pressure. GC analysis, quantification by internal standard method. The conversion of formaldehyde was 81.3% and the selectivity to diethoxymethane was 95.5%.

Embodiment 2

[0040] Same as Example 1, using 0.85g / 2.3mmol catalyst b, the conversion rate of formaldehyde is 82.1%, and the selectivity of diethoxymethane is 95.8%.

Embodiment 3

[0042] Same as Example 1, using 0.72g / 2.3mmol catalyst c, 60% formaldehyde aqueous solution as the reaction raw material, and the feeding amount is 5.0g / 0.1mol. The conversion of formaldehyde was 78.2%, and the selectivity to diethoxymethane was 96.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com