Method for separating diethoxymethane and ethanol by glycerol and water multi-stage countercurrent liquid-liquid extraction

A technology of diethoxymethane and glycerin, which is applied in liquid solution solvent extraction, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of high energy consumption and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

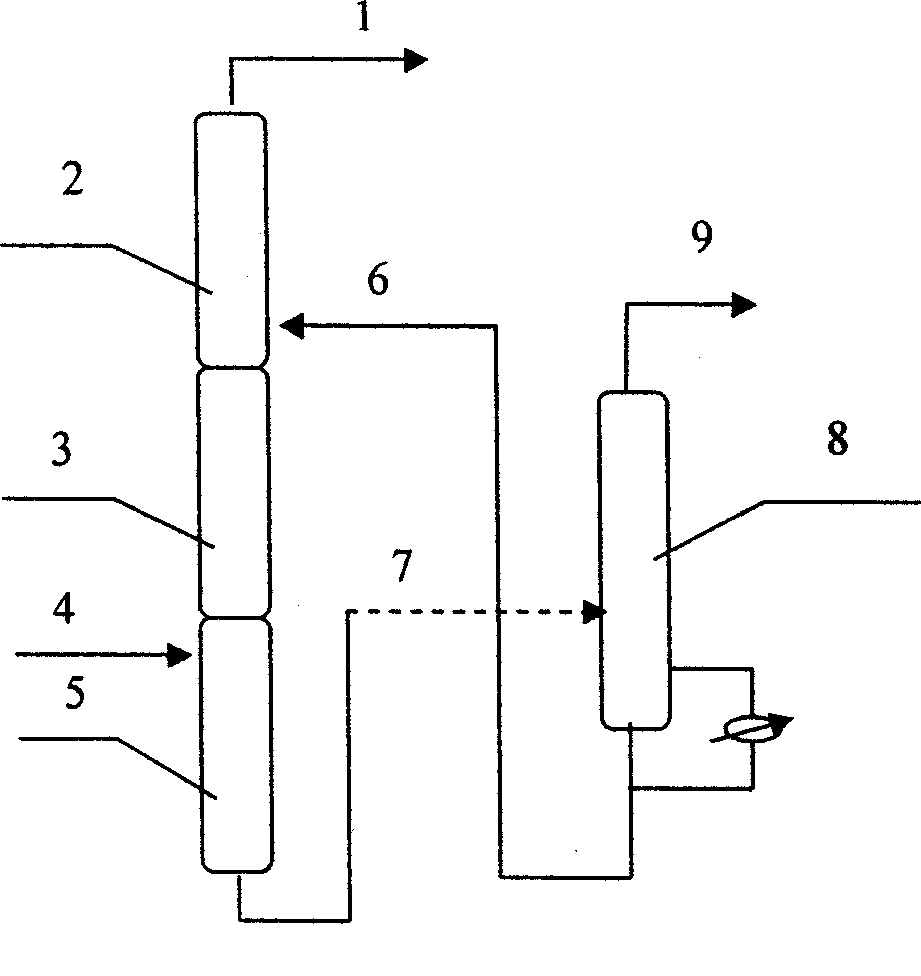

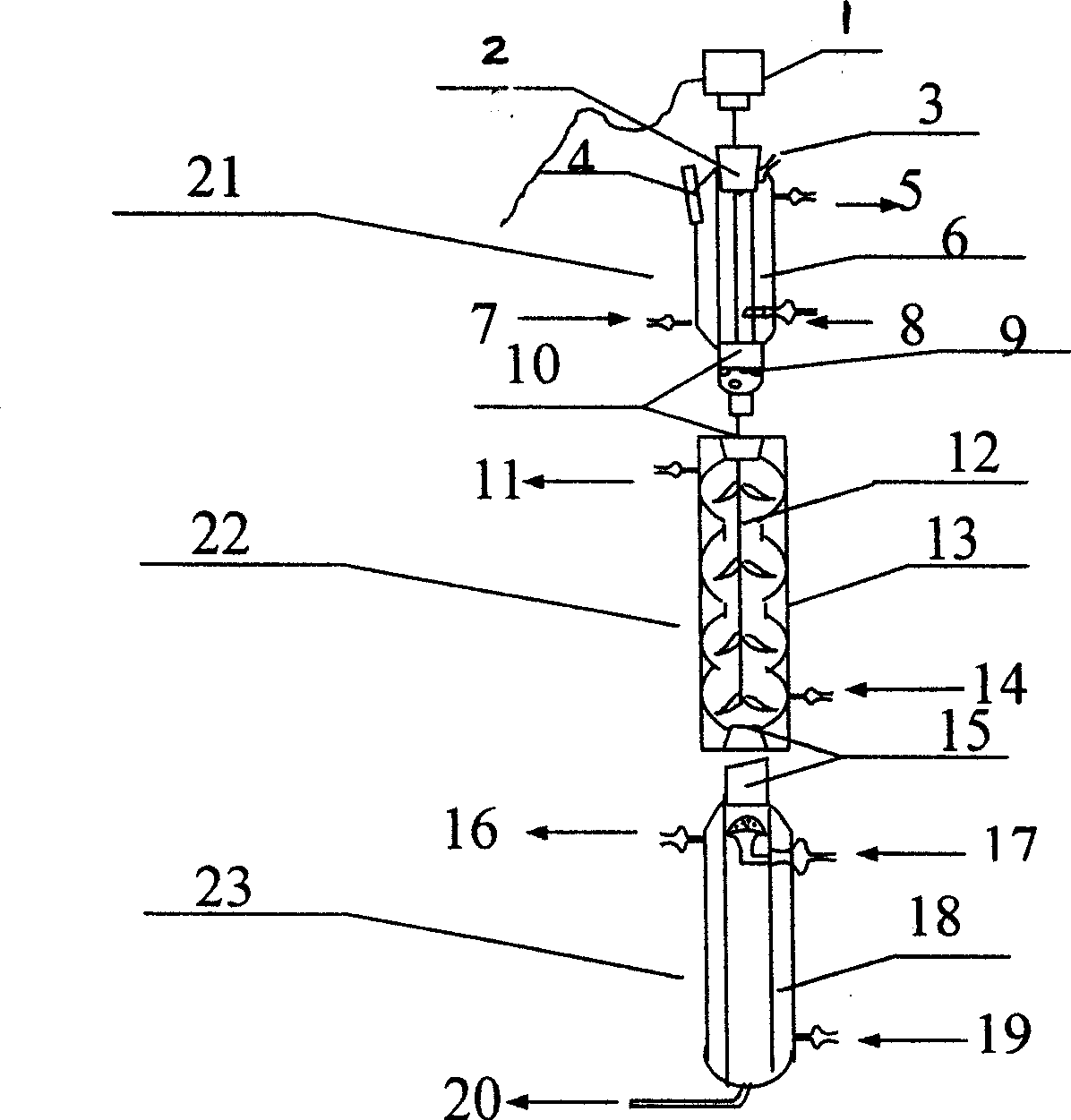

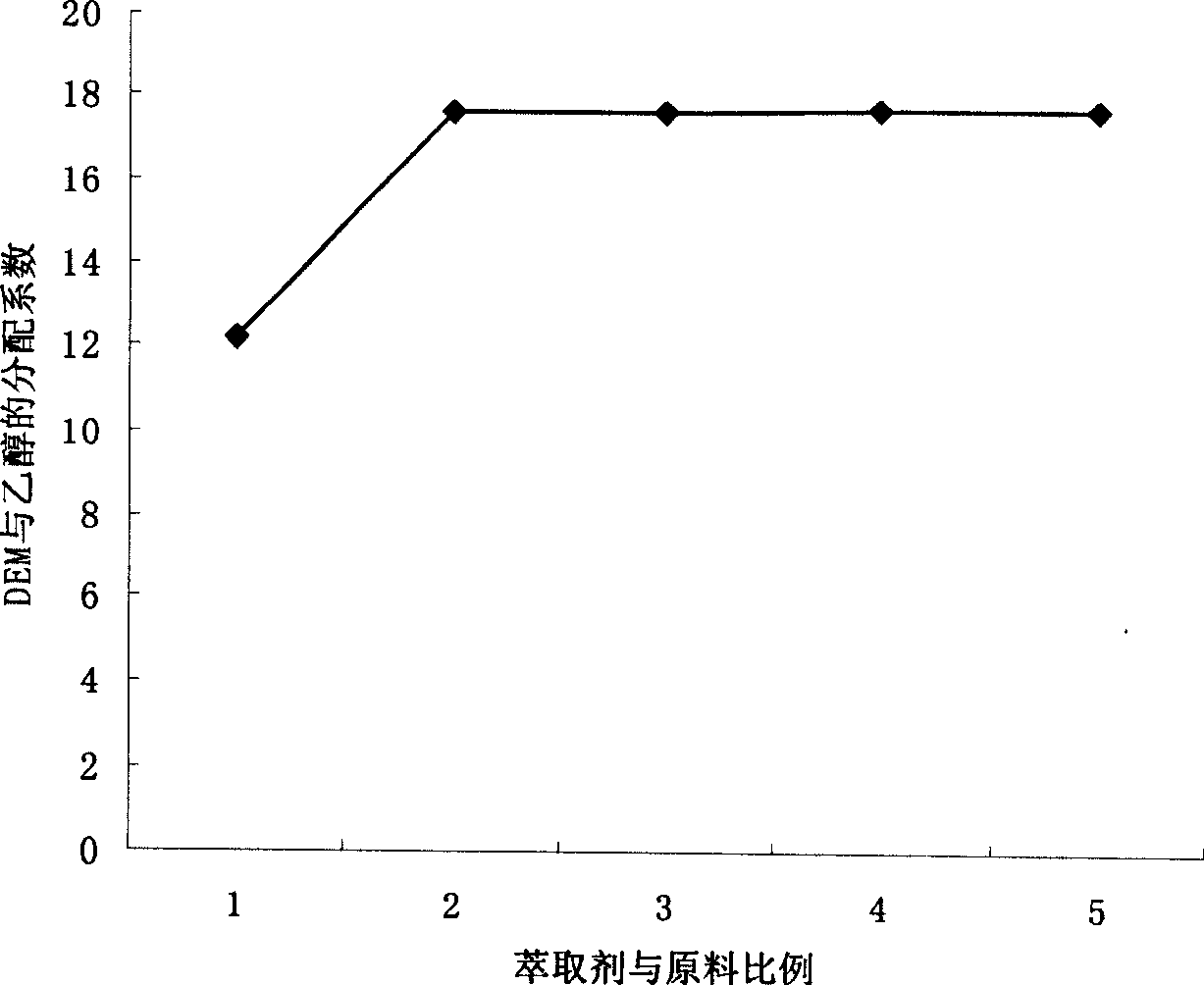

[0026] Embodiment 1, with reference to figure 1 , figure 2 As shown in the process diagram, the raw material is ethanol solution of DEM, the contents of DEM and ethanol are 92% and 8% respectively, the raw material is 20Kg, and the extractant (glycerol:water=1:1) is 20Kg. In the case of 298.2K, press figure 1 As shown in the process flow, the mixed solution is sent into the extractor and fully stirred with the inflowing extractant, separated in layers, the extraction phase (E) and the raffinate phase (R) reach equilibrium in each stage of the extractor, and the extraction phase E is formed by the refined Distillation tower processing, after separation, E and R composition are shown in Table 2 (not counting the amount of solvent), and the results of Table 2 show that through 5 stages of countercurrent extraction, the primary yield of raffinate phase (R) DEM reaches more than 98%, and the purity can reach 98%. Up to 99.7% (mass content). After E is processed by rectificati...

Embodiment 2

[0027] Embodiment 2 is basically the same as Example 1, but wherein the mass ratio of extractant to raw material is 0.5:1; the mass ratio of glycerol to water in the extractant is 1:0.5.

Embodiment 3

[0028] Embodiment 3 is basically the same as Example 1, but wherein the mass ratio of extractant to raw material is 2.5:1; the mass ratio of glycerol to water in the extractant is 1:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com