Production method of dibutoxymethane, diethoxymethane, dipropoxymethane or dipentyloxymethane

A technology of diethoxymethane and dipropoxymethane, which is applied in the field of dibutoxymethane, can solve the problems of increasing production costs, decreasing product purity, and unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

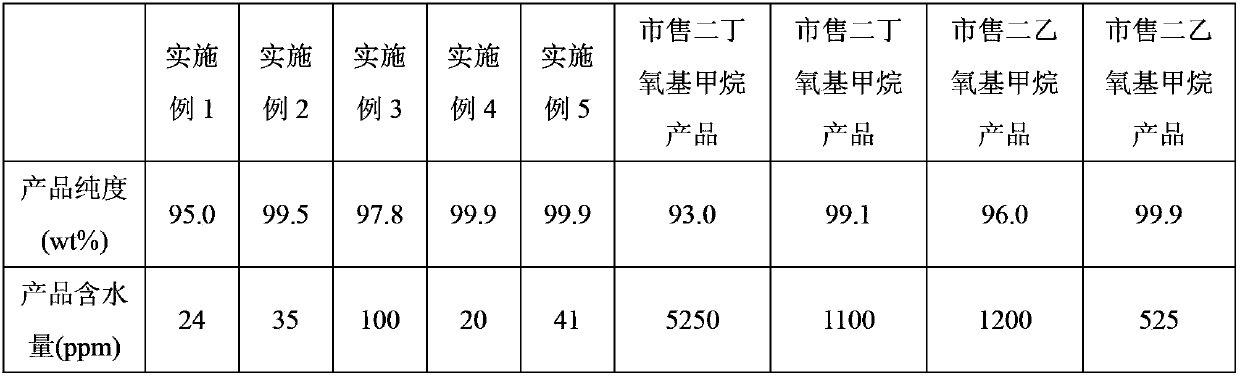

[0020] The production method of embodiment 1 dibutoxymethane

[0021] Put formaldehyde and butanol into the mixing tank at a ratio of 5:1, heat to 70°C, then add the acid catalyst to the reactor at a certain rate, and raise the temperature to 180°C, the gas continuously escapes from the reactor and enters the reactor The connected rectification tower; the system is evacuated, the pressure is controlled at -0.09MPa, and the dibutoxymethane product with a concentration of 95.0% is obtained at the bottom of the rectification tower. The top of the distillation tower is water and a small amount of organic matter, which is discharged into the wastewater treatment system. The whole production method is continuous production, no need to add dehydrating agent during the production process.

Embodiment 2 2

[0022] The production method of embodiment 2 dipentoxymethane

[0023] Paraformaldehyde and amyl alcohol are added into the mixing tank at a ratio of 1:5, heated to 160°C, then added to the reactor at a certain rate, acid catalyst is added to the reactor, and the temperature is raised to 200°C, the gas continuously escapes from the reactor and enters the reactor. The rectifying tower connected to the reactor; the system is evacuated, the pressure is controlled at -0.09MPa, and the concentration of 99.5% dipentoxymethane product is obtained at the bottom of the rectifying tower. The top of the distillation tower is water and a small amount of organic matter, which is discharged into the wastewater treatment system.

Embodiment 3 2

[0024] The production method of embodiment 3 diethoxymethane

[0025] Paraformaldehyde and ethanol are added into the mixing tank at a ratio of 1:4, heated to 145°C, then added to the reactor at a certain rate, and acid catalyst is added to the reactor, and the temperature is raised to 160°C, the gas continuously escapes from the reactor and enters the reactor The connected rectification tower; the system is evacuated, and the pressure is controlled at -0.06MPa, and a diethoxymethane product with a concentration of 97.8% is obtained at the bottom of the rectification tower. The top of the distillation tower is water and a small amount of organic matter, which is discharged into the wastewater treatment system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com