Method for preparing diethoxymethane

A technology of diethoxymethane and dimethoxymethane, which is applied in the field of preparing diethoxymethane, can solve the problems of low output, high dosage, and limited output, and achieve less side reactions, good selectivity, and high product quality. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

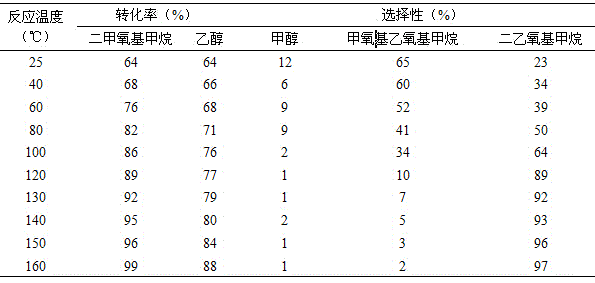

[0041] Add 30g of dimethoxymethane, 40g of ethanol and 3g of catalyst into a 200mL autoclave. The catalysts are sulfuric acid with a mass fraction of 98% (Shandong Jiuding), hydrochloric acid with a mass fraction of 38% (Hebei Yongfei), mass Nitric acid with a fraction of 50% (Hebei Yongfei), hydrofluoric acid with a mass fraction of 45% (Shandong Jiuding). use N 2 Replace the air in the kettle three times under the condition of 1.0MPa, so that the remaining air content in the kettle is less than 0.1%, and then pass 2.0MPaN again 2 , let it stand for 30 minutes, and use it to test the leak of the reactor to ensure that the device is airtight and then empty the gas in the kettle. Under the condition of ensuring no air leakage, the reaction was heated and heated. The stirring speed of the reactor was 500 rpm, the reaction temperature was 120 ° C, the reaction pressure was 3.0 MPa, and the reaction time was 6 hours. The results of controlling the catalyst type are shown in Table...

Embodiment 2

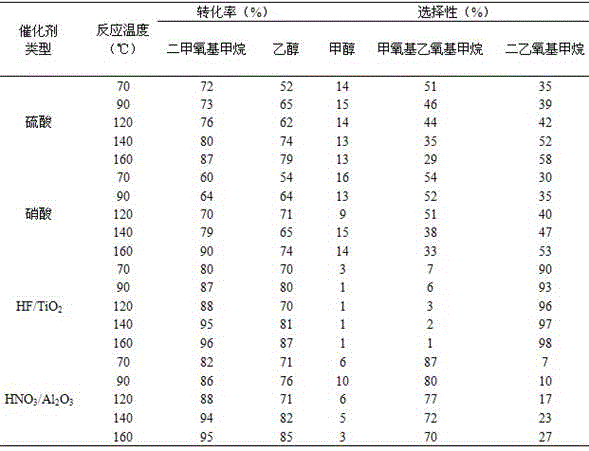

[0046] In a 200mL autoclave, the ratio of the amount of the raw material dimethoxymethane and ethanol is 2:1, 1:1, 1:2, 1:3, 1:4 and 3g hydrofluoric acid catalyst, at room temperature Next use N 2 Replace the air in the kettle three times under the condition of 1.0MPa, so that the remaining air content in the kettle is less than 0.1%, and then pass 2.0MPaN again 2 , let it stand for 30 minutes, and use it to test the leak of the reactor to ensure that the device is airtight and then empty the gas in the kettle. Under the condition of ensuring no air leakage, the temperature was raised under normal pressure, the stirring speed of the reactor was 500 rpm, the reaction temperature was 120°C, the reaction pressure was 3.0 MPa, and the reaction time was 6 hours. The results of controlling the ratio of raw materials are shown in Table 2.

[0047] Table 2. The effect of different raw material ratios on the reaction activity and product selectivity.

[0048]

[0049] As can be se...

Embodiment 3

[0051] Preparation of sulfuric acid with a mass fraction of 20% H 2 SO 4 / SiO 2 Supported catalyst, the preparation process is as follows: first put silica into a muffle furnace and roast at 500°C for 4 hours to remove the water adsorbed in silica, take 80g of silica after roasting as carrier; take 20g of 98% concentrated Sulfuric acid was diluted into 49% sulfuric acid solution, and 40g of the sulfuric acid solution was impregnated into 80g of silica carrier pores in an ultrasonic environment; ℃ roasting for 3 hours to produce H 2 SO 4 / SiO 2 supported catalyst. In 200mL autoclave, add 30g dimethoxymethane, 40g ethanol, 3gH 2 SO 4 / SiO 2 catalyst, at room temperature with N 2 Replace the air in the kettle three times under the condition of 1.0MPa, so that the remaining air content in the kettle is less than 0.1%, and then pass 2.0MPaN again 2 , let it stand for 30 minutes, and use it to test the leak of the reactor to ensure that the device is airtight and then empt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com