Continuous catalysis and rectification technology for synthesizing diethoxymethane

A diethoxymethane, catalytic distillation technology, applied in the chemical industry, sustainable manufacturing/processing, organic chemistry, etc., can solve the problems of low product purity, long production cycle, complicated operation, etc., to achieve high product purity, The effect of long production cycle and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

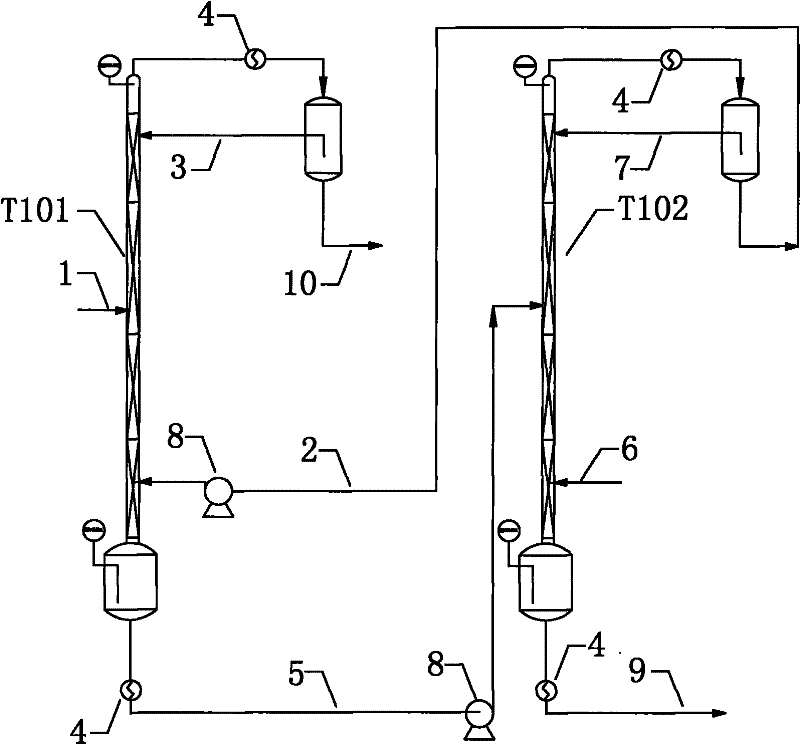

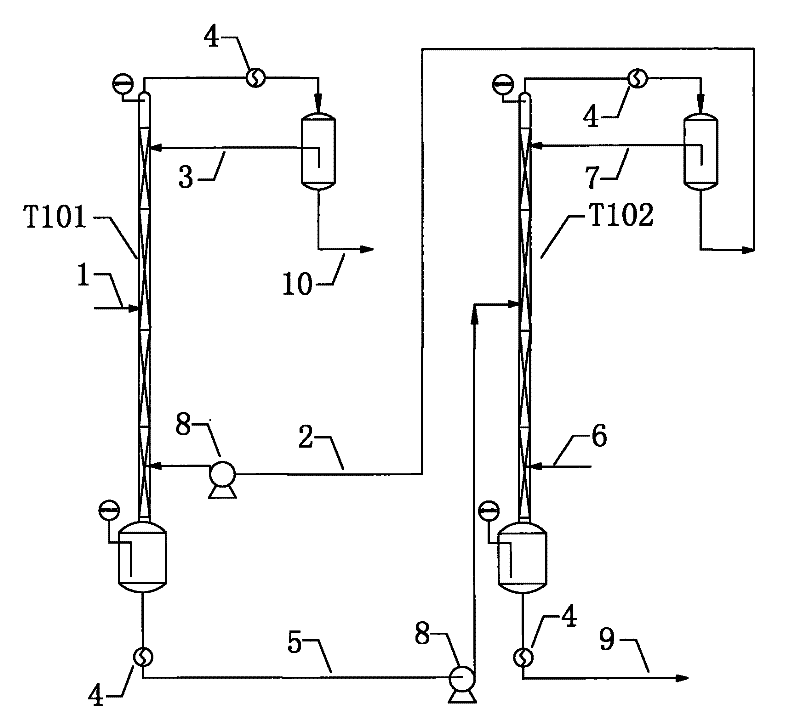

[0039] The continuous distillation synthesis process flow chart of diethoxymethane is as follows figure 1 shown. The catalytic reaction rectification tower is divided into the first-stage catalytic reaction rectification tower T101 and the second-stage catalytic reaction rectification tower T102. The reaction sections of the two-stage catalytic reaction rectification towers are filled with solid acid catalysts, and 30% formaldehyde enters through pipeline 1. To the top of T101, flow is 2.12g / min, and ethanol enters the bottom of T102 through pipeline 6, and flow is 2.00g / min, and the mol ratio of ethanol and formaldehyde is 2.051, and T101 overhead extract (diethoxymethane , unreacted ethanol and water) condenses through condenser 4, enters reflux tank, part returns T101 tower through pipeline 3, as the reflux of this reaction, reflux flow is 17ml / min, part is discharged as product through pipeline 10, and it is composed of : 2.835% of water, 1.490% of ethanol, 95.675% of die...

Embodiment 2

[0042] The continuous distillation synthesis process flow chart of diethoxymethane is as follows figure 1shown. The catalytic reaction rectification tower is divided into the first-stage catalytic reaction rectification tower T101 and the second-stage catalytic reaction rectification tower T102. The reaction sections of the two-stage catalytic reaction rectification towers are filled with solid acid catalysts, and 30% formaldehyde enters through pipeline 1. To the top of T101, flow is 2.12g / min, and ethanol enters the bottom of T102 through pipeline 6, and flow is 2.14g / min, and the mol ratio of ethanol and formaldehyde is 2.194, and T101 overhead extract (diethoxymethane , unreacted ethanol and water) are condensed through the condenser 4, enter the reflux tank, part returns to the T101 tower through the pipeline 3, and part is discharged as the product through the pipeline 10, and the discharge is composed of: water 2.670%, ethanol 7.236%, diethoxy Methyl methane 90.094%, f...

Embodiment 3

[0045] The continuous distillation synthesis process flow chart of diethoxymethane is as follows figure 1 shown. The catalytic reaction rectification tower is divided into the first-stage catalytic reaction rectification tower T101 and the second-stage catalytic reaction rectification tower T102. The reaction sections of the two-stage catalytic reaction rectification towers are filled with solid acid catalysts, and 30% formaldehyde enters through pipeline 1. To the top of T101, flow is 2.12g / min, and ethanol enters the bottom of T102 through pipeline 6, and flow is 2.00g / min, and the mol ratio of ethanol and formaldehyde is 2.051, and T101 overhead extract (diethoxymethane , unreacted ethanol and water) condenses through condenser 4, enters reflux tank, part returns T101 tower through pipeline 3, as the reflux of this reaction, reflux flow is 17ml / min, part is discharged as product through pipeline 10, and it is composed of : 2.835% of water, 1.490% of ethanol, 95.675% of die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com