Exhaust system

a technology of exhaust system and exhaust heat, which is applied in the direction of generator/motor, machine/engine, generator/motor, etc., can solve the problems of reducing the thermoelectric unable to effectively collect thermal energy, and reducing the thermal energy conversion efficiency of the exhaust heat power generation apparatus, so as to prevent the degradation of catalysts and improve fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

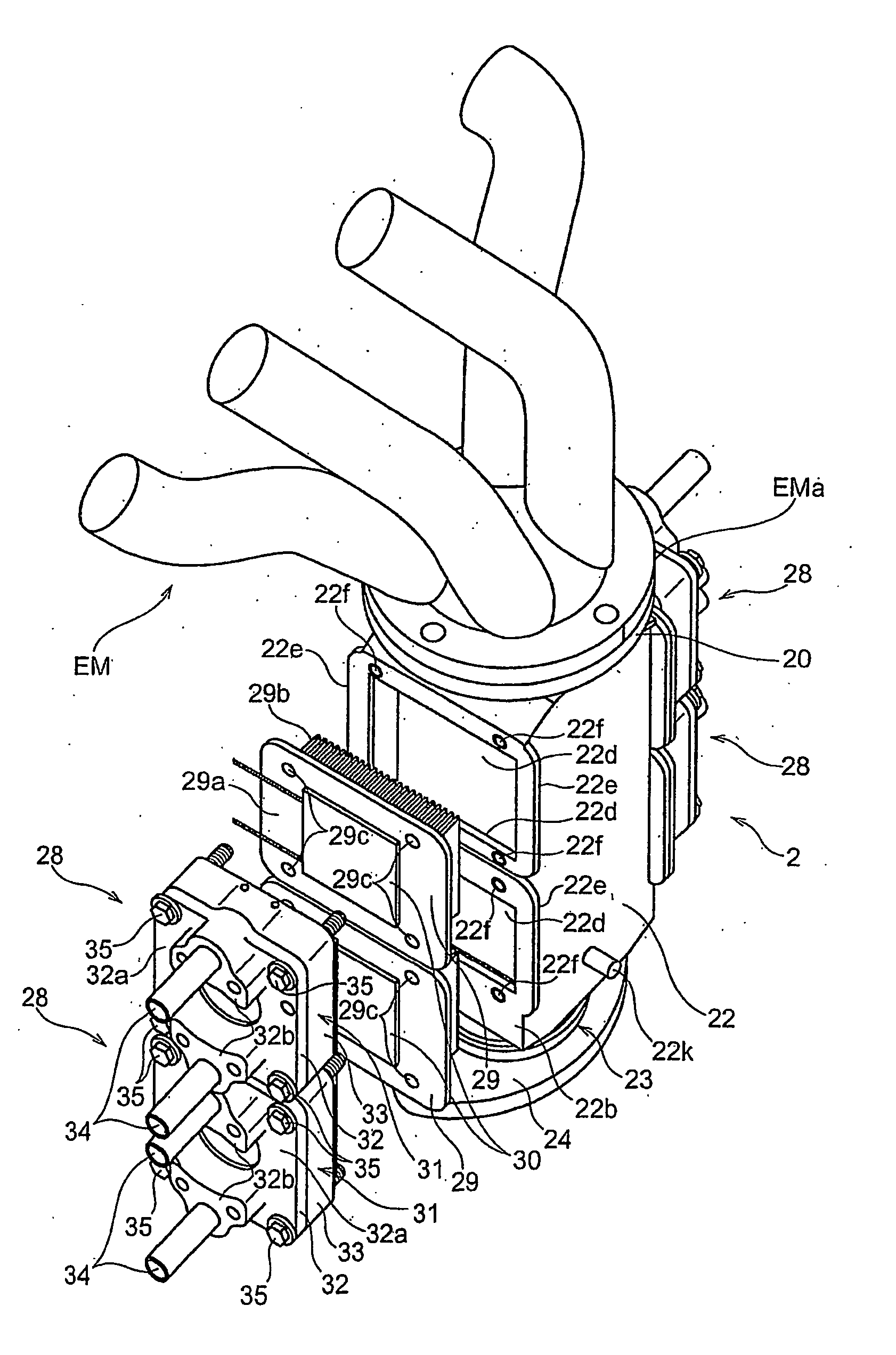

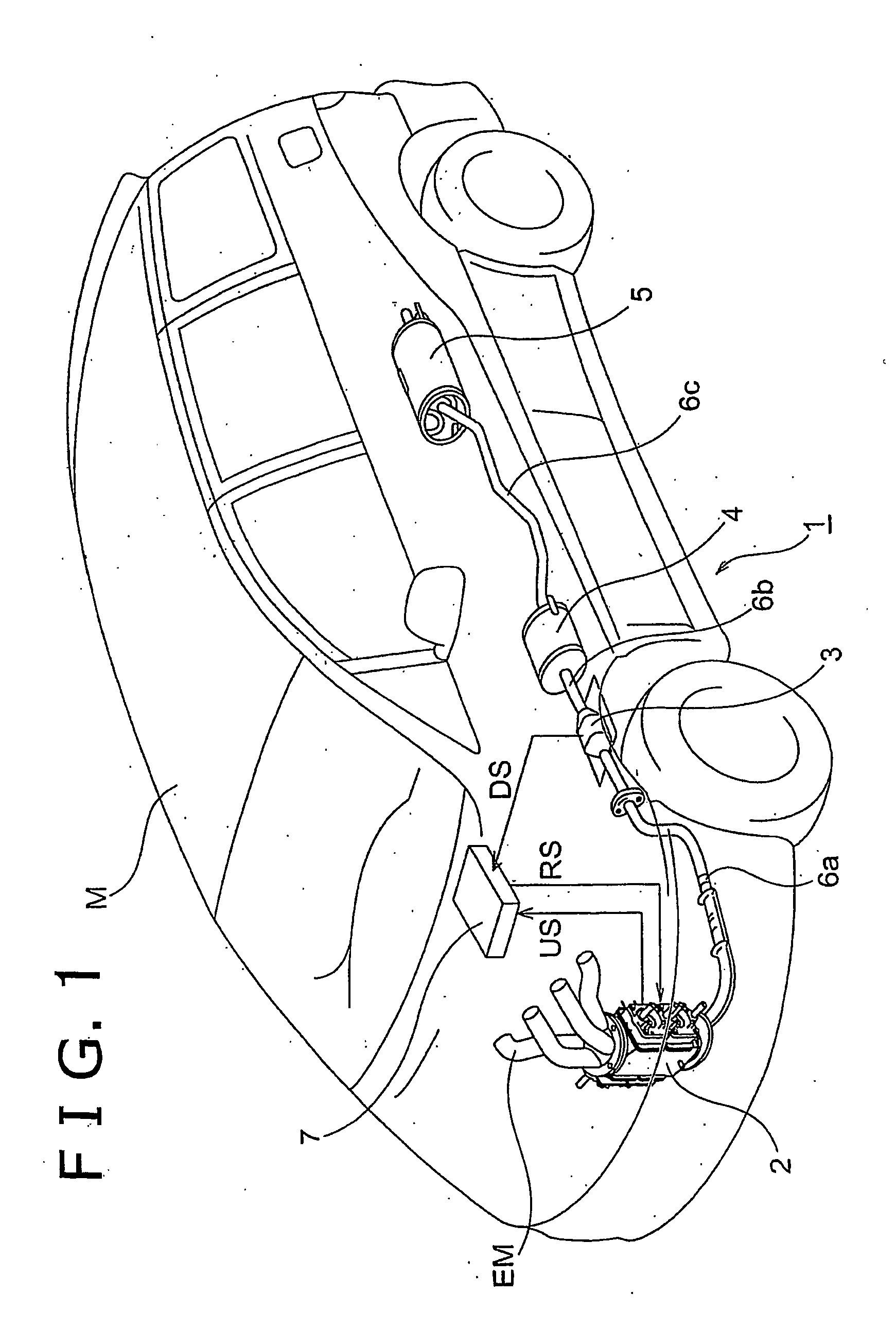

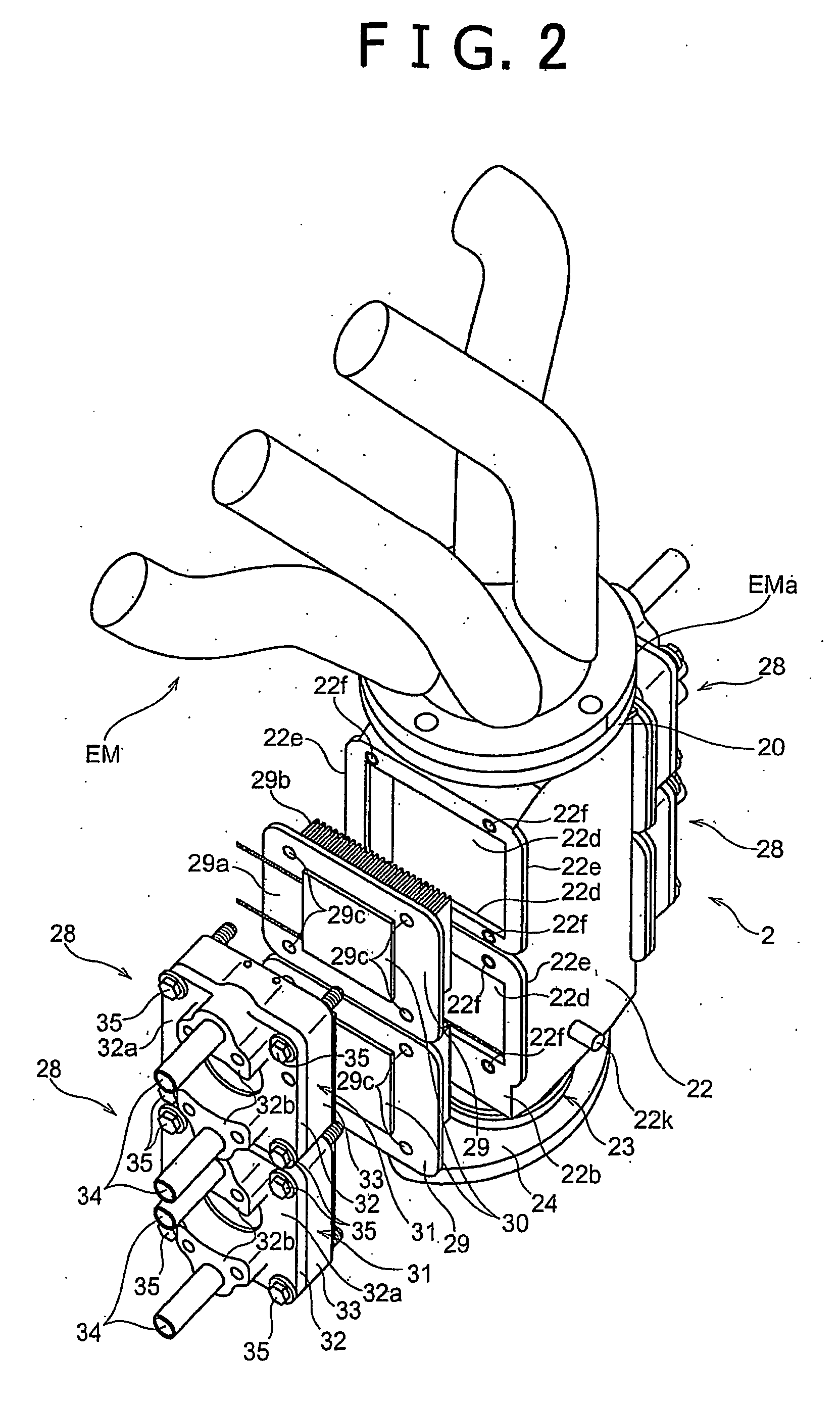

[0039] Embodiments of an exhaust system according to the invention will be described referring to the drawings.

[0040] In this embodiment, an exhaust system is mounted on a vehicle for purifying the exhaust gas from the engine while converting the thermal energy of the exhaust gas into electric energy. The exhaust system according to the embodiment is provided with two exhaust emission catalysts, one is placed in the vicinity of the exhaust manifold (hereinafter referred to as an upstream catalyst), and the other is placed downstream thereof (hereinafter referred to as a downstream catalyst). The upstream catalyst in the vicinity of the exhaust manifold is provided with an exhaust heat power generation unit. In this embodiment, no additional exhaust heat power generation apparatus other than the aforementioned exhaust heat power generation unit is provided. In the other embodiment to be described later, an additional, exhaust heat power generation apparatus is provided.

[0041] A str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com