Macromolecular material polymerization reaction kettle

A technology for polymerization reactors and polymer materials, applied in chemical/physical/physicochemical fixed reactors, mixers, mixers with rotating stirring devices, etc., can solve the problem of affecting the reaction process and polymer molecular weight, stirring failure , mechanical failure and other problems, to achieve the effect of improving the efficiency of mass transfer activities such as devolatilization, improving the stirring efficiency, and increasing the discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

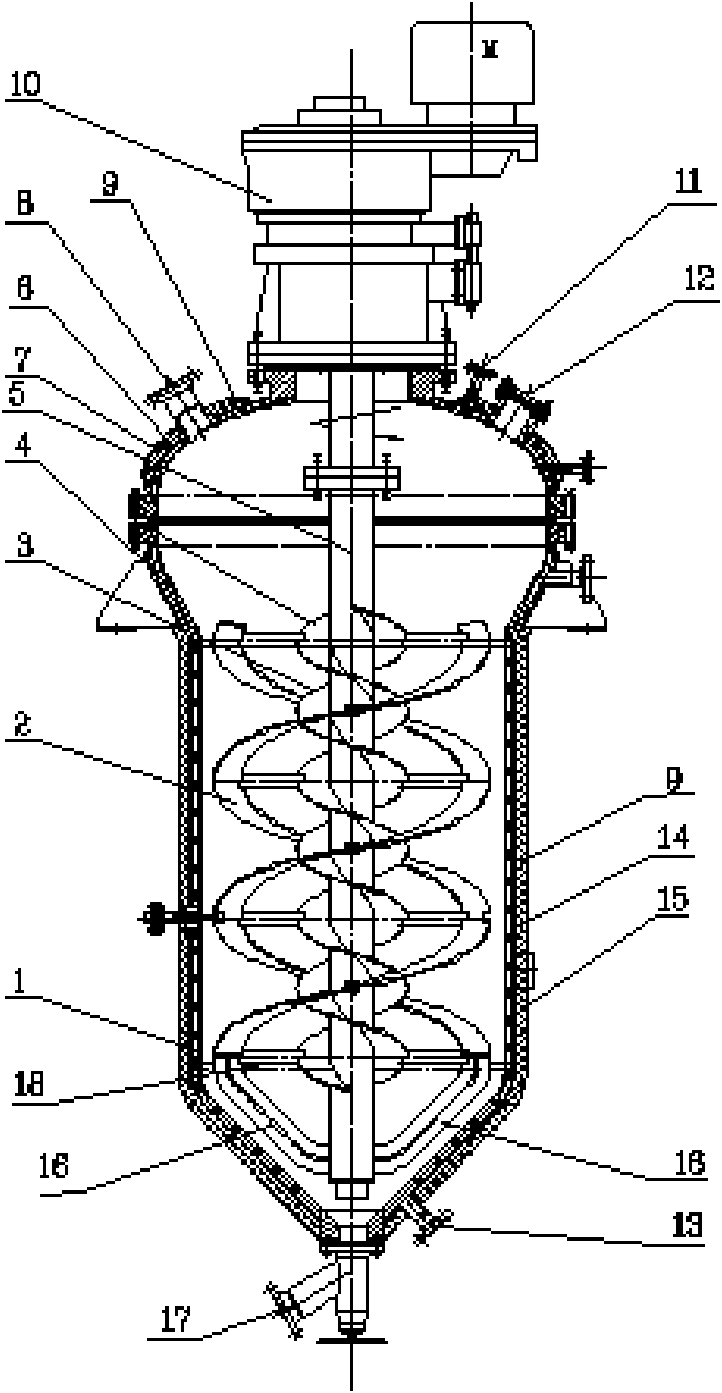

[0045] Describe a polymer material reaction kettle according to the present invention. The height of the barrel part of the reaction kettle is 1200mm, the inner diameter is 1100mm, the height of the wide mouth part is 390m, the bottom angle of the wide mouth is 60°, the bottom angle of the conical part is 90°, and the diameter of the outlet at the center of the bottom of the kettle is 100mm. Outlet valve. The jacket gap is 16mm, and the thickness of the insulation layer is 50mm. The diameter of the stirring shaft is 160mm, the width of the inner propeller blade is 100mm, and the width of the outer propeller blade and scraper blade is 100mm. The diameter of the feed pipe is 200mm, extending into the kettle by 150mm. Equipped with a water ring Roots vacuum unit with a maximum pumping capacity of 300L / s.

[0046] When the thermoplastic polyester elastomer polycondensation process with a hard segment content of 58% is carried out in the reactor, the absolute pressure is 100Pa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com