Method for producing sulfur-free honey-carrying brown sugar

A production method and technology of brown sugar, applied in the fields of sugar production, sucrose production, sugar products, etc., can solve the problems of complex production process of nutritious sugar, difficulty in popularization and application, etc., and achieve the effect of beautiful taste, mellow flavor, and promotion of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

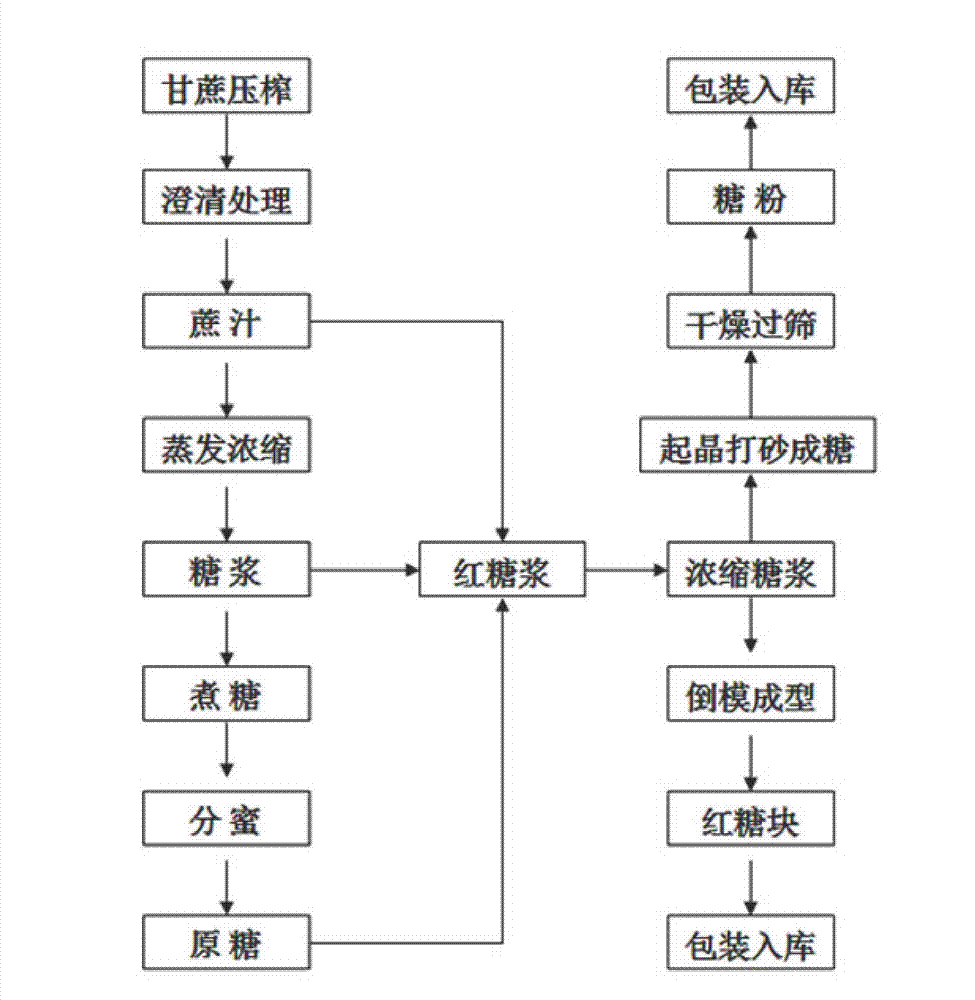

Method used

Image

Examples

Embodiment

[0033] The method of the present invention will be described below in conjunction with specific embodiments.

example 1

[0035] a. Sugarcane juice is squeezed out, including primary juice and mixed juice, and clear cane juice is obtained after clarification;

[0036] b. Send the above-mentioned clear cane juice to the evaporation concentration tank, and carry out multi-effect evaporation concentration to obtain syrup with a Brix of 60~65oBx;

[0037] c. Send the above-mentioned syrup into the sugar boiling tank, carry out the sugar boiling operation, and then obtain raw sugar with a sucrose content of not less than 95% through a nectar separation mechanism;

[0038] d. After inspection, the following raw data are obtained:

[0039] project Brix / % Simple purity / % Sucrose / % Moisture / % Initial press clarified juice 19 84 / / raw sugar 98.5 / 95 1.5

[0040]Set the quality of the brown sugar finished product as M grams, the sucrose content is 90%, and the moisture content is 1.5%, then the required raw sugar (X gram) and initial pressure clarified juice (Y g...

example 2

[0047] a. Sugarcane juice is squeezed out, including primary juice and mixed juice, and clear cane juice is obtained after clarification;

[0048] b. Send the above-mentioned clear cane juice to an evaporation concentration tank for multi-effect evaporation concentration to obtain a syrup with a Brix of 60-65 oBx;

[0049] c. Send the above-mentioned syrup into the sugar boiling tank, carry out the sugar boiling operation, and then obtain raw sugar with a sucrose content of not less than 95% through a nectar separation mechanism;

[0050] d. After inspection, the following raw data are obtained:

[0051] project Brix / % Simple purity / % Sucrose / % Moisture / % syrup 65 85 / / raw sugar 98.5 / 95 1.5

[0052] Set the quality of the brown sugar finished product as M grams, the sucrose content is 90%, and the moisture content is 1.5%, then the required raw sugar (X gram) and initial pressure clarified juice (Y grams) dosage. That is:

[0053...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com